Management — Lean Flow in Sales and Marketing

The focus of lean flow is to lean out the process, and make the product flow. So how can sales and marketing help achieve this goal? Below are four areas that have a major impact on your efficiency. Some of these are very controversial and that’s why they have never been addressed:

- Product Rationalization

- Order Minimums

- Cut-off Times

- Customer Rationalization

Product Rationalization

This is one topic that most growers say they address every year, but never really take action to improve on it. How many products do you grow? How many products of similar colors do you grow? How many different shades of red, or pink of the same variety do you offer your customer? These are all questions that we should be asking ourselves. Have you ever wondered what the impact of having so many items/SKUs has on production or shipping? The typical answer we get is “Our customers buy from us because they get all of their products from us.” That may be your perception. Have you ever asked your customer if they would buy another item, if the one that they buy (which is very low volume) were no longer offered? You may be surprised by what the answer may be.

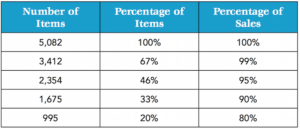

Since lean flow is based on math, we will let the results of a sales analysis guide us to the right decision. By completing a sales analysis of all your items, we can make a decision based on fact and not emotion. A sales analysis (Table 1) using the 80/20 rule is a great place to start. The 80/20 rule states that 80 percent of your sales comes from 20 percent of your items. If you do this analysis with your Items you may be surprised how close the results come to the 80/20 rule. Table 1 is an example of this type of analysis. In this study, the customer sells 5,082 different items. The results here were very substantial. You can see that by reducing the items sold to 3,412 or 67 percent of the 5,082 items you would only reduce sales by 1 percent.

With the understanding that sales are not this cut and dry, there will be some items at the bottom of the list that you will have to continue to sell because they are what we call “lost leaders.” You don’t make any money on them, but you get customers to buy other products that have a good profit margin. These lost leaders should not be confused with, “I like these plants and so do our customers.” Remember let the analysis, not gut feel, drive you to the correct decision.

Order Minimums

Now that we’ve reduced the number of items we offer, we need to look at the minimum order quantity that we offer to our customers. Another area that has a great impact on the efficiencies of a company is the quantity that we let our customers purchase. The order minimum is not a dollar minimum; it is a quantity minimum. Many growers say they have a $1,000 minimum, but they let their customers buy one of each of the items they sell. Think of the implications that this has on the shipping department. They have to go to many locations to pull one product.

This increases the amount of time to pick an order, thus reducing the efficiency and profitability of your company. Again, we hear quite often, “Our customers buy from us because they know they can buy one of an item.” However true this may be, it does not make it right.

Typically, there are two types of customers: the big box retail stores and the independent garden centers (IGCs). Most growers that supply to the big box stores have a minimum quantity; usually it’s a half shelf or full shelf minimum. The growers that sell to IGCs typically have no minimums.

If you were to do a time study on picking a rack of plants that has no minimum, compared to a rack with a half shelf minimum the results might surprise you. Once you recognize the difference in time and then multiply that time by the amount of racks you produce, the cost implications will astound you.

The question is, do you know how much more money it is costing you to allow no minimum order quantities? Or more importantly, if it’s costing you more money, are you selling it for more — probably not? Again, you need to do the math and see how much more it costs you to sell in quantities of one. You may change your opinion once you do the math and see the results.

Cut-Off Times

When we ask growers, “What are your cut-off times?” we typically get one of two answers. They either tell us “We don’t have one,” or “It’s at noon or 1 p.m.” followed by a “but.” The “but” means that there really isn’t a cut-off time. They let their customers place orders all day long. Although this may look good for sales, it has a major impact on the shipping process.

When we talk to shipping managers or supervisors they tell us that this type of behavior causes major disruption when they have an order already pulled, picked and ready to load into the truck. Getting a call from sales using the dreaded term “add-on” or “change” can cause a shipping dock to come to a screeching halt.

The question in this case we must ask ourselves is, what is the cost of adding to the order after it has been picked? We have seen growers take racks off a truck that has been loaded just to add more product to an order.

Understanding that a process can be developed to achieve anything, you need to consider the cost implications of doing this. In a lot of cases you spend more money jumping through hoops to change the order, than the additional sales is worth.

So how do we address the issue of sales saying no? Sometimes we just need to say, “We can’t add to your existing order, but we can put it on the next truck that is going to your area.” These may be tough words to tell your customer, but if you continue to satisfy last minute changes, you will continue to reduce your profitability. The rule of thumb we use is, once the master pull has been created no more changes will be allowed. The master pull is a compilation of orders, typically a half day’s worth. Once the master pull is created, the loads have been built and all the paperwork is printed out. Any changes to an order after the master pull is created is only creating havoc for the pulling and shipping crew. Set a cut-off time, and stick with it. You will be surprised how your customers will begin to abide by the cut-off time, only if you enforce it.

Customer Rationalization

As if the first three topics weren’t difficult enough to put your arms around, did you ever wonder if you should reduce the number of customers you have? Now this goes against the conventional thinking of a sales person. The more customers you have the more sales you get. Just for a minute, let’s discuss another type of conventional thinking, “Sometimes less is more.” Less customers can mean more profits.

Just as we rationalized our product offering, what if we do the same analysis with our customers. Take the sales of all your customers and perform the 80/20 rule analysis. You will see that 80 percent of your sales come from about 20 percent of your customers. This doesn’t mean that you should get rid of 80 percent of your customers, but it does mean you should rationalize the customers whose sales are at the bottom of total sales. In some cases, the customers that are providing the least percentage of sales are the ones that demand the most attention.

Just as it is more time consuming to pick an order with no minimums, it’s also time consuming and costly to pick very small orders. Although it’s a tough decision to make you need to do the analysis and let the math guide you to the right decision.

As we know, lean flow is a business strategy that affects all parts of the business. It is now time to look outside of the traditional areas we usually focus on and start looking at the sales and marketing area where there are many changes you can make to get lean and improve the company’s profitability.

Got Questions?

Want to learn more about how Lean Flow can impact all aspects of your business?

Gerson Cortés will discuss “What’s Next in the Greenhouse … and Your Office?” at the 2017 Big Grower Executive Summit, Oct. 1-3, in Wakefield/Boston, Massachusetts.

To learn more about the program or to register to attend go to www.biggrower.com/executivesummit.

Video Library

Video Library