Clean Up Your Water with Carbon Filtration

Are pesticide residues in your irrigation water suppressing crop growth or causing phytotoxicity? Filtration using granular activated carbon (GAC, Figure 1) in most cases is the best solution to remove pesticides from water. This article provides guidelines on design and operation of a GAC filter for greenhouses and nurseries.

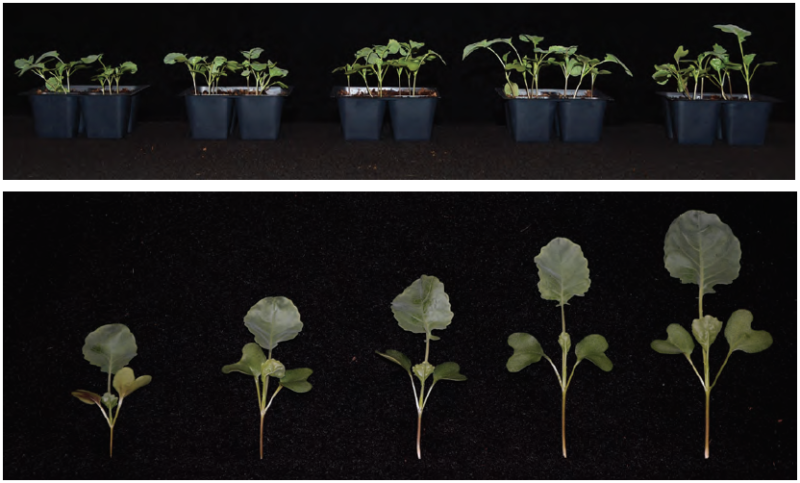

Agrichemicals in water can be an issue in several situations. Persistent chemicals can accumulate in recirculation systems and affect subsequent crops even in the parts per billion (ppb) range (Figure 2). Growers using pond water occasionally experience a problem when herbicides are applied to surrounding land in the water shed and crop growth is suddenly deformed (Figure 3).

Hydroponic and aquaponic growers may need to remove chlorine from a municipal water supply to avoid phytotoxicity. Some growers treat recirculated water with a high dose of chlorine or another sanitizer for control of resistant waterborne plant pathogens, such as Fusarium spores, and need to remove the sanitizer before reusing the water. Regulations may require remediation of chemicals that have harmful environmental impacts, such as bifenthrin, before irrigation runoff leaves a property.

BROAD RANGE OF ACTIVITY

GAC filtration is a simple and cost-effective technology to

remove agrichemicals compared with other options, which include ozone and ultraviolet radiation. At the University of Florida, we tested GAC remediation of several chemicals that included insecticides (acephate, bifenthrin, chlorpyrifos and imidacloprid), herbicides (glyphosate and triclopyr) and plant growth regulators (flurprimidol, paclobutrazol and uniconazole) at one tenth of label rates to simulate diluted levels in nursery runoff. Providing 64 seconds of contact time under research conditions with fresh GAC filter media removed over 90% in all cases except bifenthrin (72%) and imidacloprid (85%). These results lend confidence in using GAC to remove a wide range of pesticides, although a longer 15-minute contact time is recommended in commercial conditions.

GAC filters were also very effective at removing sanitizers (quaternary ammonium chloride at 7-ppm active ingredient, sodium hypochlorite at 2-ppm free and total chlorine, and a combination of hydrogen peroxide + peracetic acid at 58 ppm and 4 ppm). Levels were non-detectable with 64 seconds of contact time. These results indicate GAC is effective at removing a sanitizer after treatment in recirculated water.

A GROWER CASE STUDY

A grower in northeastern U.S. generously shared information about their installation of GAC. In this case study, the grower collected and re-used irrigation drain water from 20 acres of subirrigated greenhouse production space, resulting in approximately 1,450,622 gallons of recycled irrigation water filtered annually by GAC. The treatment goal was to remove paclobutrazol to below 5 ppb.

The larger the flow rate, the bigger (and more expensive) the filter. In the case study operation, return water from the ebb-and-flood system first went into a holding tank. It was then pumped at a slow flow rate (50 gallons/minute) through three 264-gallon (1,000 pound) GAC vessels in series before being recycled for irrigation. To calculate the required filter volume for a 15-minute contact time, multiply the flow rate (in this case, 50 gallons/minute) x 15 minutes = 750 gallon volume. By running the filter for several hours per day at a low flow rate, cost was reduced in the case study operation.

Ensuring there is adequate pre-filtration is important. First, use a coarse screen, sand, or paper filter to remove large particles from return water. At the case study location, irrigation solution passed through a series of 50- and 5-micron polyester bag filters (Figure 4) before receiving GAC filtration. GAC filters can be back-flushed, and pressure gauges should be placed before and after the filter to indicate when a backflush is necessary.

Although this was not an issue at the case study operation, GAC filters can also become clogged with bacteria and algae, and if the source has a lot of microbial growth (such as pond water) it may be necessary to sanitize (for example, with chlorine) before passing water through the GAC. Remember that GAC will remove most of the sanitizing agent, so if a residual sanitizer is required post-GAC then a sanitizer will need to be re-injected.

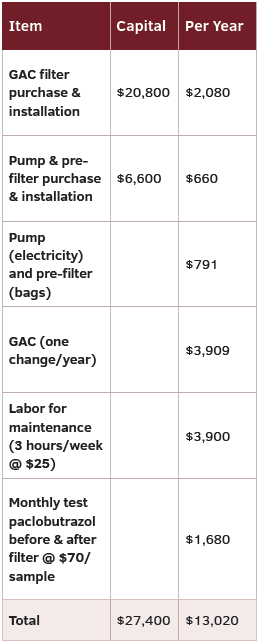

The system cost $27,400 to set up (Table 1), with annual costs of $13,020 to treat ≈1.4M gallons = $8.97/1,000 gallons. This is a significant cost, and the benefit would only occur if you have either a proven issue of pesticide residue (based on crop symptoms and water tests) or a serious risk such as a surface water supply that is vulnerable to herbicide contamination by surrounding land users.

Each GAC filter contained 8×30 U.S. mesh (595–2380 micron) bituminous coal-based GAC. We have tested both coal and coconut shell-based GAC, and both were equally effective at removing paclobutrazol. A particle size around 8×30 is important to ensure adequate surface contact to allow adsorption of the target chemical onto the carbon, but still allowing sufficient water flow rate through the filter.

A common question is how often the carbon needs to be replaced. Chemicals adsorb to the carbon particles, eventually filling the exchange sites, and the GAC will no longer function effectively. In the case study operation, GAC was replaced once annually by the GAC supplier at an annual cost of $3,909 (Table 1).

To check that the GAC is functioning correctly or if carbon needs replacement, before and after water samples were taken weekly by the case study operation and sent to Waters Agricultural Labs for testing of paclobutrazol concentration. Over 17 months of testing, the post-GAC level of paclobutrazol never reached above the 5-ppb target level even though pre-treatment levels reached as high as 73 ppb.

To save costs, we recommend monthly (rather than weekly) testing of the target chemical before and after GAC. When sending in a water sample to test, let the lab know the specific target agrichemical to avoid a very high analytical cost.

There are other ways to check whether the filter is still effective. Broccoli seedlings can be sown and irrigated with your raw recirculated water, GAC-treated water, and clean (bottled or tap) water (Figure 5). Check growth after two to three weeks as a non-specific chemical bioassay. Begonia plugs are another good “canary in the coal mine” for paclobutrazol.

You can also check non-target chemicals before and after GAC filtration. For example, we found that GAC is very effective (95% removal after 64 seconds) at removing the soracid blue dye used to color many water-soluble fertilizers. In addition, 48% of iron-EDDHA at 2-ppm iron was removed at the same GAC level. Both fertilizer dye and Iron-EDDHA provide a visual indicator of GAC efficacy (Figure 6). In addition, if you are repeatedly treating a recirculating nutrient solution containing iron-chelates, it is likely that you will need to add iron back into your water after filtration.

In this article, we covered several aspects to consider on the design and operation of GAC filters. If you are interested in using GAC to treat irrigation water, please contact the authors for more information.

Video Library

Video Library