Cover Story — A Solid Foundation

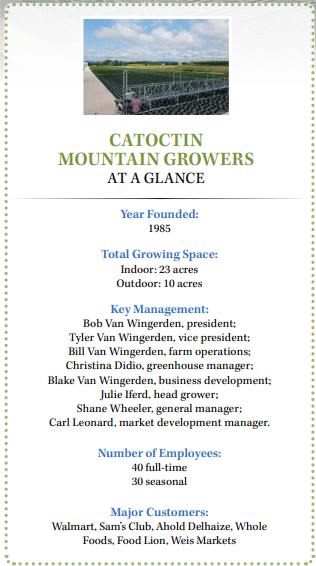

Keymar, Maryland, may be a small, unincorporated community with a population of fewer than 3,000, but it’s home to a major player in our industry: Catoctin Mountain Growers.

population of fewer than 3,000, but it’s home to a major player in our industry: Catoctin Mountain Growers.

In 1985, Bob and Denise Van Wingerden married, moved to Carrol County, Maryland, and built the first acre of their greenhouse business — all in the same year. They started selling contract to other greenhouses and then retail outlets, all while slowly growing the operation.

Today, the Van Wingerdens’ 1 acre has expanded into 23 acres indoors and another 10 acres outdoors. Catoctin Mountain Growers, however, continues to have family at its core. All four of Bob and Denise’s children (Tyler, Bill, Christina and Blake) grew up at the greenhouse and are now back working in the business.

We caught up with Tyler, vice president of the company, to discuss the keys to their success and plans for growth.

A COMMUNITY STAPLE

Tyler has great memories of working in the greenhouse all throughout his childhood, even starting to gain some retail experience as a 6-year-old.

“My dad let my brother and I work on weekends when we were in first grade,” he says. “People would come in and shop. There’d be maybe 20 or 30 people, not a lot, and [my dad] would give us a cut, so we would get to sit there and sell plants.”

This first retail venture has organically grown into something the community looks forward to every season, even though it only accounts for a percent or two of sales. Saturdays throughout the spring, mostly in March, April and May, individuals can come out to the greenhouse, grab a rolling rack that’s normally used for shipping, and shop.

“Now it’s a bit more of an ordeal, and we put a little more effort into it than having first graders man the registers,” Tyler jokes. “People have access to basically the whole greenhouse. They walk around and pick up what they’d like, bring it to the front, and we check them out.

“A lot of people enjoy just being in a 20-plus acre facility of lots of beautiful annuals. That’s a fun experience, and it’s an event for some people. It’s nicely priced bedding plants as well, so they enjoy that.”

FOCUSED ON GROWTH

At Catoctin Mountain Growers, a long-term mindset shapes all business decisions, which is especially apparent in its greenhouse structures. Tyler says they buy their greenhouses with 30-year plans in mind, so they aren’t having to deal with facilities that are ripped, falling apart or torn up 10 years later.

“Financially, yes, you have to put more money up front, but year in and year out, labor only goes up, cost of plants only goes up. All those things are always increasing and becoming more difficult, so we try to build in as much efficiency in the capital side when we’re building a project,” Tyler says. “It also makes working in it much more enjoyable. Our employees are not working in windy, ripped, open houses. It’s all tight glass and metal structures that are very easy to keep clean, very easy to stay organized within. It allows us to have long-term sustainability as a company.”

Catoctin has greenhouses that are 30 years old and just as viable as some of the new greenhouses. The booms are still working, there aren’t windows ripped out, the concrete is still in great shape, etc.

“I’ve been here for my whole life, and I have children now who are very young, and I don’t know if they’ll be in the greenhouse or not,” Tyler says. “But I want these buildings to be here and in good shape for them if they may take over at some point.”

Catoctin Mountain Growers is currently working on a building project that has been in the pipeline for a while. Five new acres should be up and running by March for this spring season. The facility will be modern, up-to-date and relatively automated.

“We’re setting ourselves up to be a company that can last and compete into the future as supply chain changes, as labor market changes and as products change,” Tyler says.

In the spring, Catoctin Mountain Growers focuses primarily on annuals, but it’s continuing to grow its perennial portfolio.

“Something we’re really leaning into is to offer more plants, more of a variety, so our customers are able to get more of what they need at one stop with us,” Tyler says. “This isn’t a novel idea, but something that we’re leaning into more now, going into 2024.”

In addition to spring crops, the business also grows fall mums, fall annuals, poinsettias, and rosemary and lavender plants shaped like trees.

AUGMENTING LABOR

Finding good team members is top-of-mind for most businesses, and this rings true for Catoctin Mountain Growers. Tyler says as they continue expanding, they’re always looking to find employees who can have a productive influence on the work they do and have the energy and desire to try new things.

Catoctin has approximately 70 employees, 40 fulltime and 30 seasonal, who bring a lot of expertise. “Our employees are very important to us,” Tyler says. “I’ve grown up right here, and a lot of the employees have been here for a long time. Just this fall we celebrated three employees’ 20-year anniversaries.”

A generous profit-sharing program helps retain good employees and shows them how important they are to the business.

“It’s very transparent for the employees. We share with them honestly what our profit number is, and we have a formula that depending on the number and depending on the threshold, there’s a piece that’s shared with the team,” Tyler explains. “We try to be very open with that and help to encourage people that if we work as a group and make this company more profitable, everybody directly benefits.”

This bonus program is the same formula for every level of employee, whether they’re at a starting wage or a senior manager at a higher wage. Tyler says there are busy weeks for sure, but they want to make sure there’s a good balance of time where people can decompress and have the pay be in line with the effort.

Tyler has a labor-centric approach to automation as well.

“We’re growing and trying to grow rapidly where I say I’d like to have automation augment the labor that exists, so I don’t have to do that next hire. I’m not firing the existing team member, but when I add 2 acres or 5 acres or whatever it is, my team of 70 can still be a team of 70,” Tyler says. “I have 70 people taking care of 5 more acres of greenhouse because automation augments their abilities. It allows them to do more, it allows them to grow more, it allows them to produce more.”

Specifically, Tyler is keenly aware of and trying to work on augmenting the irrigation team.

“On this team, you have to have people who know plants, they can feel plants, they understand the biology, understand the science and how to grow crops,” he says. “The intelligence is there, the capacity is there, but sometimes physical limitations and mundane tasks like turning on faucets, walking hoses, or moving irrigation booms slows down their ability to grow more.”

chain and labor market change.

INNOVATION & SUSTAINABILITY

Catoctin Mountain Growers has two major technology projects going on currently. The first is in partnership with IUNU, a Seattle-based developer of AI and computer vision greenhouse management systems.

In December, Tyler and his team installed IUNU’s camera system as a trial in an acre of the greenhouse. The system uses robotic optical scanners on tracks to assess plant growth, predict harvests, detect anomalies and track inventory. Tyler hopes to get familiar with it and see what type of information it gives back and what it’s like growing plants relying on this feedback.

“It’s hard as a grower who is used to literally picking up plants and touching them and sticking your finger in the dirt to switch to relying on computer sensory input to make decisions on plant growing. That’s a big paradigm shift,” Tyler says. “This is a really neat leap forward in growing plants, especially bedding plants, monitoring them with the camera, looking at growth rates, germination, and hopefully plant health, counts, and inventory tracking.”

Tyler hopes that relying on computer intelligence for menial tasks can help the talented growers on the team have the time to be more innovative and focus on higher-level thinking, more-creative thinking.

Catoctin Mountain Growers’ second project right now is with the University of Maryland and focuses on energy usage in manufacturing facilities, including “plant manufacturing.” Three specific targets are lighting, heating and irrigation.

“On the heat side, we’re looking at measuring the heat circulation and where we can capture more day, natural heat, sun-heat, and not have to put in supplemental heat from boilers,” Tyler says. “Then on the irrigation side, we have some flow meters put up on a couple of our irrigation booms now, and so we’re measuring actual gallons put down on crops and then correlating that to other variables like sunlight, temperature, humidity, and things of that nature.”

Building this database can help save energy not only with potentially less watering but also with less growth regulators by eliminating overwatering by accident. Tyler and his team are trying to be more objective in when they water, why they water, how much water they put down and how this watering correlates to pot size and plant type. A third huge energy expense for any greenhouse operation is lighting.

“From a lighting standpoint, we’re doing things like measuring light, being really specific and picky on when we turn lights on for certain crops and putting in dimmable LEDs rather than just on-off, high pressure sodium (HPS) type,” Tyler says.

In addition to its work with the University of Maryland, Catoctin Mountain Growers received a grant from Maryland’s state-backed agency TEDCO to help convert some of its HPS lighting to LEDs, in what Tyler refers to as a “stars-aligned type of situation.”

The grant was specific to agriculture companies in Maryland working with technology companies in the state. Horticultural lighting company JumpLights Inc. found the grant and, already having a relationship with Catoctin, urged them to apply.

Tyler and his team were able to convert approximately an acre of HPS to LED with very little cost on their end, one piece of the puzzle to shrinking its energy usage.

“Cutting down on electricity saves us money right away,” Tyler says. “But we think it’s good for the environment. The less we use the better.

“We grow plants and natural products that are good for the earth, and we want to do as little damage to the natural environment as we can. Sometimes you forget, there’s a blurry line, between just normal business practices here and sustainable efforts.”

Catoctin Mountain Growers hopes to tweak its soil mix to become a more sustainable company as well. Tyler has been meeting with local manufacturing facilities who have a lot of scrap wood from making trusses and parts for houses. It’s pine lumber, making it a viable option for potting mix.

“We’re looking at taking that and getting grinding systems here to turn it into basically a sawdust that we can put into our potting mix to help offset some of the costs of peat moss and other things that go in our mix,” Tyler says. “That’d be nice to get rid of trash from one group and put it back into a living plant that’ll end up in a garden somewhere.”

Sidebar: Catoctin Hemp

In 2019, the Van Wingerden family decided to expand their growing expertise into a new category. Catoctin Hemp was born, and although it’s a separate business entity, it still operates in the same facilities as Catoctin Mountain Growers and is owned and operated by the Van Wingerdens.

“We’re learning a lot. It’s growing; it’s slowly growing. It’s not the gold mine everybody expected it to be three or four years ago when everyone was diving into it like crazy,” Tyler says. “A lot of people have left and aren’t in it anymore, but we’ve become believers in it, so that’s why we’ve stayed.” Tyler Van Wingerden, second generation leadership and vice president, shared a case study of how CBD has helped his dad, owner Bob Van Wingerden.

“He has arthritis and was on prescription medication. And since we’ve been doing the hemp business and he’s taking the pills that we make here, he’s off all prescriptions,” Tyler says. “We have stories like that from customers who buy our products, so that type of stuff keeps us going. We totally believe in the plant and the product.”

Tyler’s brother Blake runs the day-to-day operations of Catoctin Hemp. In addition to the growing facilities, the business has an 80,000-square-foot climate-controlled drying facility and an extraction lab. They are a true seedto-shelf company, making all its CBD products on-site and selling them both retail and wholesale.

“It’s such a different world than gardening, so we’re getting a lot of exposure to huge players and then super niche players,” Tyler says. “We would be a really small, niche player in it, and then you have these Charlotte’s Web and massive national brands. It’s been interesting to interact with all those different levels.”

For an enhanced reading experience, view this article in our digital edition by clicking here.

Video Library

Video Library