Cover Story — Generating Success

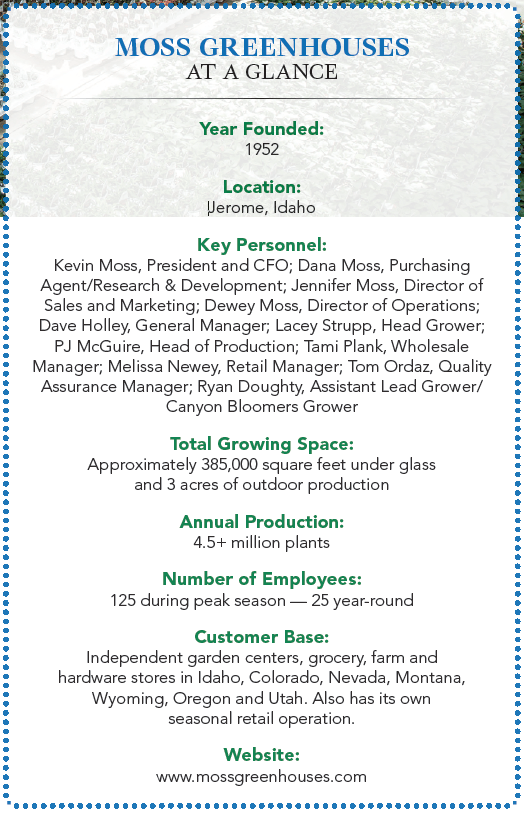

Over the years, Moss Greenhouses, situated in the high desert altitude of Jerome, Idaho, has established its reputation as a producer of some of the highest quality plants in the West.

As the company approaches its 70th anniversary and the fourth generation of the family prepares to take the company reins in the coming years, Moss Greenhouses is well positioned to continue its upward trajectory for the long haul.

A few days after Mother’s Day, Big Grower had the opportunity to talk to fourth-generation family member Jennifer Moss (an alumnus of GPN’s 40 Under 40 Class of 2020) and learn a little bit about how Moss Greenhouses got its start, why it has been successful for so many years and where the company is headed.

A few days after Mother’s Day, Big Grower had the opportunity to talk to fourth-generation family member Jennifer Moss (an alumnus of GPN’s 40 Under 40 Class of 2020) and learn a little bit about how Moss Greenhouses got its start, why it has been successful for so many years and where the company is headed.

FROM THE FIELDS TO THE GREENHOUSE

Moss Greenhouses’ roots were established in 1952 when Ed and Ruth Adams (Jennifer’s great-grandparents) made the decision to turn their plant growing hobby into a business. “If you ever see any old pictures of my great-granddad, he’s always got a cigar in his mouth and a plant in his hand,” Jennifer says.

After more than a decade of operating their family farm, Ed and Ruth decided to become wholesale growers and built a 100-square-foot greenhouse to grow cut flowers and potted crops for grocery stores and floral shops in the region.

In the early days, the company established itself as one of the best orchid growers in the country thanks to their attention to detail and the ideal growing conditions in Idaho.

The company really began to grow when Generation Two, DeWitt and Carolyn Moss (Ed and Ruth’s daughter and husband/Jennifer’s grandparents), joined the family business in 1973. The company continued to build greenhouses to produce bedding plants for its existing customers while adding new customers every year.

Ten years later, Kevin and Dana Moss (DeWitt and Carolyn’s son/Jennifer’s parents) returned to the Magic Valley to help with the company’s latest greenhouse construction project. Kevin was instrumental in the launch of Moss Seedling to produce plugs for other growers back when there were not too many growers specializing in plugs.

In 1996, Kevin and Dana purchased the company from Dewitt and Carolyn and continued their expansion with the addition of even more greenhouses. They also made the decision to exit the plug production business following the transition as the company grew.

Today, Moss Greenhouses has more than 380,000 square feet of greenhouse production with an additional 3 acres of outdoor production space to serve customers in seven states in a 600-mile radius of Jerome (Idaho, Colorado, Nevada, Montana, Wyoming, Oregon and Utah).

Approximately 85% of the company’s revenue is wholesale growing, while the remaining 15% is the company’s retail operation that is open four months (March-July) of the year.

TALKIN’ ‘BOUT THEIR GENERATIONS

Ownership of Moss Greenhouses has passed through three different family generations and now Kevin and Dana’s children, Jennifer and Dewey, are preparing to lead the company into the future. The Moss family has developed a

well thought-out and gradual succession plan for the company. “We’ve already been talking about succession for four years now, and we’ve got another two years to go. That’s not a short road to walk down.”

Like their father and grandfather before them, after graduating from college, both Jennifer and Dewey pursued careers outside the horticulture industry before returning to the family business. This provided them with additional perspectives about the plant business and about themselves.

“You had to work for someone else before you came back to the family farm. And after you came back, you have to learn how to do every single job on this farm and be willing to do so,” Jennifer says.

“I’m good with people, marketing and vision and Dewey’s really good at finance, planning and strategizing. So, between the two of us, we each have a skill set that will really help continue to drive the company,” she adds.

“We have figured out how to work as a family that likes and respects each other,” so the business and the relationships always remain healthy. While there will always be minor disagreements, “We have a very workable family relationship and we all get along most days of the week,” she jokes.

“Our biggest goal with the transition from generation to generation is we wanted our parents to be here overlapping for continuity,” Jennifer says. “We want to make sure the company doesn’t suffer as well as the employees. They are a part of the Moss family.”

To take care of these family members, 15 years ago, Kevin and Dana started an Employee Stock Ownership Program (ESOP) so today the company is 35% employee owned, while the Mosses own the remaining 65%. Jennifer says the ESOP provides a really good retirement plan for employees who stay with the company for a while.

Jennifer and Dewey will take over the 65% as Kevin and Dana exit the company in the next few years.

BETTER NOT ALWAYS BIGGER

When asked what does the company attribute its success to, Jennifer responds, “Our biggest strength is we produce the best quality plants in our market. Our selections have really been fine tuned for our market.

“We want to make sure we offer the best quality at all times. It is very important for us that better is more important than bigger.”

Jerome’s growing climate has its benefits and challenges. At an elevation of nearly 3,800 feet, Moss Greenhouse has very high light levels but it also has weather extremes — oftentimes in the same week.

“We trial and test everything for our climate. We have got to have plants that can handle a bit of diversity when it comes to our temperatures,” Jennifer says.

One way they do that is by cold toning the plants. “It was 82 degrees here yesterday and it’s supposed to snow later in the week.” Cold toning the plants helps the home gardener be more successful in spite of what Mother Nature might throw at them in a given week.

“We are always trying to get better at what we do before we grow. We want to make sure that we are always doing the best for our customers.

“Our rule with our wholesale customers is, if you don’t like it, if that plant is not up to your standards, you put it right back on the truck and don’t pay for it.” Something that rarely happens.

A CHALLENGE BECOMES AN OPPORTUNITY

Labor is a major challenge for all growers — large and small — and the pandemic made it even more challenging. Moss Greenhouses competes with many other agricultural-based companies in the region for labor as well as with many large corporations that are moving to Idaho and offering much larger compensation packages and benefits to potential employees.

Last year’s stimulus checks along with increased unemployment benefits for potential employees in an agricultural-based state like Idaho really hurt their hiring. “We weren’t able to get bodies through the door. We’re not in a large metropolitan area where you had a lot of people [looking for jobs].”

So, during the off-season they took that challenge and turned it into an opportunity to simplify what they do and how they do it. By streamlining their product offerings and eliminating approximately 30% of the items, they were able to operate more proficiently. “We had a lot of redundancy … so we streamlined the whole selection process and, in turn, that meant the production runs were faster, they were more efficient” in the greenhouse as well as in the office.

“Going forward, we know we are going to have to do more with less … so in our next off-season we are going to really fine tune our processes even more,” Jennifer remarks.

She anticipates they will have to pay more for labor in the future, but she knows they will be able to maximize their productivity by cross-training employees to work in multiple areas of the company. This also allows the team at Moss to plan ahead, order inputs earlier and work further in advance.

Wherever they can, they look for ways to automate any processes they can. Both her father and grandfather received engineering degrees and “processes and technology are something we really believe in. We have automation in every house in some capacity or another.”

They are always looking for new technology. “We try to stay as current as possible within our budget and what the needs of the company are at any time. With the labor market as it is, you really have to be looking ahead on any piece of equipment or building.”

RETAIL HAS A LIFE OF ITS OWN

According to Jennifer, the retail operation at Moss Greenhouses has a personality of “her” own. “She’s one of our best [wholesale] customers. She gets the benefit of getting whatever she needs, but she has to order just like any other wholesale customer,” Jennifer says. “But she’s also kind of the perfect trial ground for any new programs. I can test things with her to see how retail customers react.”

But, Jennifer adds, the Moss wholesale pricing strategy does not provide any “family discounts” for the retail operation. “We never want [our retail operation] to compete against our wholesale customers. [Our retail price] is always a full markup of our wholesale price in our retail center. We never budge on that. We

want to give our wholesale customers every opportunity to make as much money as possible on our products.”

Jennifer says when it comes to marketing she is always focusing on the next generation of consumers, not their current customer base. One of the key areas she is aiming at is the houseplant category. “I’m a firm believer in the Plant Parent movement. Houseplants are something our industry has to pay attention to because they are the ‘gateway drug’ for millennials and Gen Z. We have got to pay attention to that generation because they are going to dictate completely new buying patterns in the future.”

Jennifer says when it comes to marketing she is always focusing on the next generation of consumers, not their current customer base. One of the key areas she is aiming at is the houseplant category. “I’m a firm believer in the Plant Parent movement. Houseplants are something our industry has to pay attention to because they are the ‘gateway drug’ for millennials and Gen Z. We have got to pay attention to that generation because they are going to dictate completely new buying patterns in the future.”

The retail operation also offers custom container planting, educational and entertaining events for consumers and students, socially distanced greenhouse tours and other related activities.

Regular Facebook Live sessions in the garden center are popular with customers. During these sessions, Jennifer “walks and talks” around the garden center showing off the latest and greatest products while answering consumers’ questions.

A DIVERSE FUTURE

As Moss Greenhouses prepares to enter its eighth decade in business, the Moss family is always looking for new opportunities that they can specialize in.

“We are always trying to diversify,” Jennifer says. They have added more and more houseplants to their catalog that they re-wholesale to their customers. Even with supply challenges facing the industry, the category is growing rapidly for the company.

Last winter, they trialed a caladium program for the holiday season instead of growing poinsettias. Initial response was very positive and Jennifer says the are continuing to evaluate the product line for the future.

They also grow shoulder crops such as carrots, beets and potatoes. And, they are participating in a natives projects where they have been growing Douglas fir trees in test tubes that eventually will be planted as part of fire/drought restoration projects.

And the company has plans to begin a new program to produce hemp plant startlets on a contract basis for hemp farmers.

“We are diversifying our menu, so to speak, focusing on [other categories] because we want to keep our people here year-round, but we have to have enough for them to do.

“We’re being asked to do a lot of different things. We need to make sure that [they] fit within our core business and business policies … and make sure we are always really good at what we do!”

Jasmina Dolce is managing editor of GPN magazine. She can be reached at jdolce@greatamericanpublish.com.

Video Library

Video Library