Cuttings in the Tropics

In March, I ventured down to Central America to visit three of Dümmen Orange’s production facilities that are relatively close together. I gave you an inside look at Antigua Flowers, a new perennial production facility in Antigua, Guatemala, in the June issue of GPN.

This month, I want to take you across the border to Las Mercedes in El Salvador. Las Mercedes opened in 2008 and is situated on approximately 300 acres, with greenhouses currently taking up more than 70 acres. A concrete wall spanning more than three miles surrounds the perimeter.

Las Mercedes specializes primarily in spring crops — think petunia, calibrachoa, verbena, dahlia, impatiens and begonia, as well as poinsettia — according to the farm’s general manager, Carl Kroon.

Why El Salvador?

“There is a good climate with a lot of light even during the rainy season,” Kroon says. “We also wanted to be close to the markets, and 85 percent of our production goes to North America.”

The farm is a massive operation that produces 250 million cuttings a year and employs 500 people year-round with an additional 1,000 people during the high season.

The People

Dümmen Orange’s Las Mercedes has attained all three MPS certifications: MPS-ABC, focused on environmental impact; MPS-GAP, looking at Good Agricultural Practices; and MPS-SQ, which stands for Socially Qualified and looks at how employees are treated.

Related to that third recognition, on our tour we heard a lot about what Dümmen Orange does to go above and beyond for employees, both seasonal and fixed.

“We try to get the same seasonal employees back,” Kroon says. “Often when they leave at the end of the spring season, they already have a letter in their hands offering them a position for the following season.”

Education is an important component for both Las Mercedes employees as well as their families.

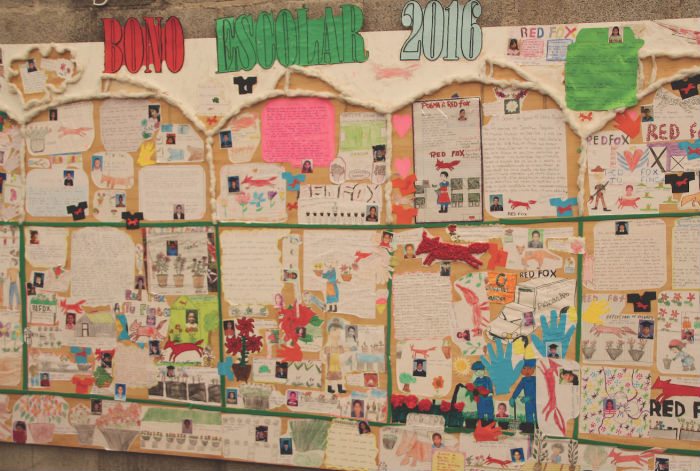

All employees with school-aged children can participate in a program called “Bono Escolar” that provides a subsidy for $30 worth of school materials at a local store. Parents must fill out a form while little children often draw a picture and older children write a story or poem that are posted in the lunchroom.

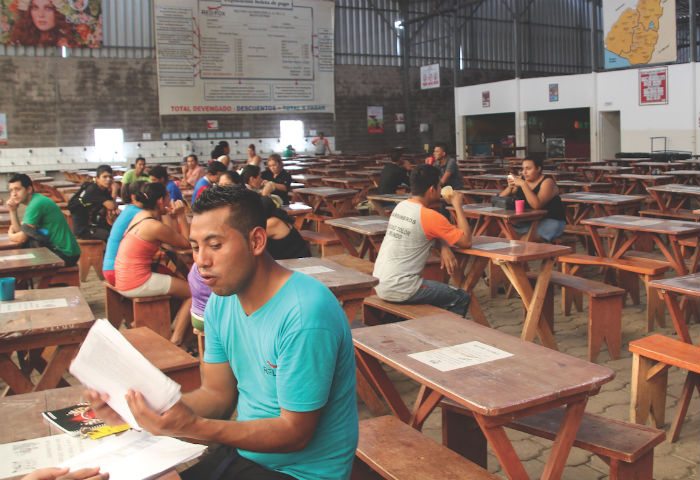

For employees, they can participate in the “Bachillerato Para Adultos” program in order to obtain a high school education.

“A lot of our workers are very intelligent but simply never had the opportunity to go to school because school was too full, they didn’t have money, they had to work, etc.,” Kroon says.

Official teachers come to the farm on Wednesdays, so many employees attend class then, and flexible hours allow them to make up the production work at a different time.

Another education program, “Bono Universitario,” is aimed at employees who are already higher up in the company, such as group leaders.

“We select candidates for this program that show potential and a strong desire to advance and we help them get admitted into university and support through to graduation,” Kroon says. “They attend classes in the evenings so after work they go to university here in Santa Ana.”

Lastly, Las Mercedes has a partnership with the University of Florida; workers can get certificates by taking online horticulture courses in Spanish. The farm even has a cyber café for those people who might need a computer for work-related courses.

The team at Las Mercedes continues to think of things to make the job better. For example, the farm has extensive sanitation protocols, requiring employees in high-risk areas to shower when they come in and go out.

“Most employees only have cold water at home and we want to make sure that they wash their hair and really shower before entering our facilities, so you have to make the showering experience attractive,” Kroon says. “We have warm water, and after the shower, we have hair dryers for the ladies.”

Coffee is always free, and food vendors provide affordable meal options.

The Product

Kroon says that one of the benefits to Las Mercedes is that they were able to design it exactly how they wanted and modeled it after the Good Seeds and Plant Protection (GSPP) system, which originated with tomato seed production.

“The backbone of the system is that you create separate entities: red locks which are from outside to inside, and then green locks which are between one unit and another,” Kroon says. “You have dedicated people and material for each particular unit that don’t contact other units.”

One way of avoiding risk specifically for the Elite houses is to keep them completely separate from the rest of the farm. Workers go straight there without coming into contact with anyone else.

As for the petunia and calibrachoa houses, they are split into smaller compartments to minimize any potential issues.

“These greenhouses are 18,000 square meters or 4 acres and they’re split into eight compartments,” Kroon says. “Each compartment has its own clothes, and own teams.”

The clothes are color coded, so if someone is wearing yellow, they can only be in the yellow compartment, blue in the blue compartment, etc.

If an issue does arise, the idea is that the effects won’t be widespread. Las Mercedes also has a lab on site to test in a timely manner for bacteria and viruses.

Protocol includes labeling each sample and pot from the exact same spot, so they can track and trace all testing.

Timing is like clockwork on the farm with harvesting during the day, packing in the afternoon and evening, cuttings leaving the farm around 4 a.m. and getting on the first flights around 8:30 a.m.

“The most important part of the chain is at the airport before they go into the airplane,” Kroon says. “Once they’re in cargo, it’s cold up there.”

For this reason, Dümmen Orange recently installed its own cold area at the airport in a similar fashion as the cold rooms on the farm.

This is just one more step to make sure the cold chain is maintained from the farm to the thousands of final greenhouse destinations across the U.S. and Canada.

Abby Kleckler is retail editor for GPN. She can be reached at akleckler@greatamericanpublish.com.

Video Library

Video Library