Growing Better Greenhouse Microgreens

(To see larger versions of the images, click here to access a .pdf file of this article)

The recent popularity of microgreens in the culinary scene has proven to be a potential source of significant income for greenhouse growers both as a primary and secondary commodity crop.

While the definition of microgreens varies widely, these crops are best defined as edible vegetables and herbs harvested shortly after emergence of the first true leaf or leaves but prior to leaf expansion.

With few publications focused on their cultivation, growers are often challenged with experimenting in-house at their own financial expense. The intention of this article is to expose the reader to a small handful of environmental and cultural practices, aimed at optimizing microgreen cultivation.

These can then be tailored to most greenhouse operations, both large and small and can have a significant effect on microgreen yields. The treatments that were explored in this research include seeding densities, fertilizer concentrations, substrate depths, and air temperatures.

WHAT TO GROW AND HOW TO GROW IT

The process of determining which microgreens you should grow varies widely depending on environmental conditions, market supply and demand, seed availability and compatibility with existing greenhouse crops if you are adding them to an existing operation.

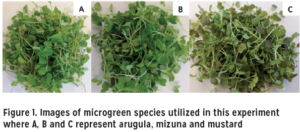

Three microgreen species; arugula (Eruca sativa L.), mizuna (Brassica rapa L. var. japonica) and mustard [Brassica. juncea (L.) Czern. ‘Garnet Giant’] were chosen for this study (Figure 1). They were selected to represent the diversity in sensory attributes for both vision and taste. In addition they not only represent popular crops on the market but also share similarities in seed size and number of days from seeding to harvest.

In practice, microgreens can be cultivated in a variety of systems ranging from soilless media in trays to capillary mats in troughs. A primary commonality between all systems is the use of high-density plantings.

The influence of seeding/population density on yield has been well established in traditional agronomic/horticultural crops such as corn and lettuce but little information exists on its effect on microgreens.

The influence of seeding/population density on yield has been well established in traditional agronomic/horticultural crops such as corn and lettuce but little information exists on its effect on microgreens.

Adding an additional layer of complexity to the decision-making process, recommendations for specific seeding rates vary widely by seed supply company and typically are not specified according to plant species or cultivar. While the availability of online resources is constantly shifting, at the time this research was conducted, Johnny’s Seeds (Fairfield, Maine) recommended the use of approximately seven seeds per square inch or 2.46 g per 10 x 20 inch tray for arugula, 2.87 g for mizuna and 2.79 g for mustard. In contrast, Mountain Valley Seed Company (Salt Lake City, Utah)  suggested an average seeding rate of 25.5 g per 10 x 20 inch tray for arugula, 29 g for mizuna and 27.5 g for mustard.

suggested an average seeding rate of 25.5 g per 10 x 20 inch tray for arugula, 29 g for mizuna and 27.5 g for mustard.

These are the general production methods we followed in our experiments (unless otherwise noted): Seed was broadcasted over a peat/perlite potting mix (Lambert LM-111) in 10 x 20 inch trays containing 2401 cell inserts (i.e., 24 cells per tray). Trays were overhead watered with a water-soluble complete fertilizer (Jack’s 21-5-20 at 150-ppm nitrogen) and covered with a propagation dome followed by a tray placed over the top of the propagation dome to induce darkness. Seeds were left exposed on the media surface and germinated at 68° F for 48 hours before the dark dome was removed. The germination dome was removed 48 hours thereafter. Trays were overhead watered on an as-needed basis with Jack’s 21-5-20 at 150-ppm nitrogen and plants were harvested when the average first true leaf measured a half inch in length.

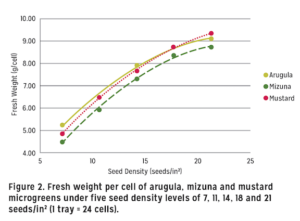

We investigated five seed densities ranging from 7 to 21 seeds per square inch, which correlated to seed weights of 2.5 to 7.4 g/tray for arugula; 2.9 to 8.6 g/tray for mizuna; and 2.8 to 8.4 g/tray for mustard.

We investigated five seed densities ranging from 7 to 21 seeds per square inch, which correlated to seed weights of 2.5 to 7.4 g/tray for arugula; 2.9 to 8.6 g/tray for mizuna; and 2.8 to 8.4 g/tray for mustard.

For all three cultivars, harvested fresh weight (FW) increased as seed density increased from seven to 21 seeds/ tray (Figure 2). Greatest FW yield increases occurred between seven and 11 seeds/tray at 24 percent for arugula, 32 percent for mizuna and 33 percent for mustard with diminishing returns above 18 seeds per square inch for all cultivars.

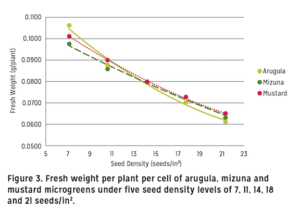

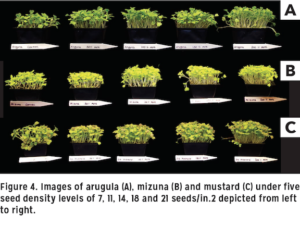

In contrast, fresh weight per plant decreased as seed density increased (Figure 3). At low population levels, individual plants were more compact with larger cotyledons, while those at higher densities were taller and had smaller leaves (Figure 4). Depending on your target market, it may be advantageous to produce one type of crop over the other.

FINDING THE RIGHT FERTILIZER

Across the United States, many small- to medium-sized greenhouse growers are highly diversified with respect to the crops they grow. Based on observations, many growers use the same growing media and fertility treatments across crop species (such as vegetable transplants and bedding plants). Furthermore, a commonality we found among growers was the assumption that the addition of a complete water soluble fertilizer was not needed, because the plants were harvested at such a young stage.

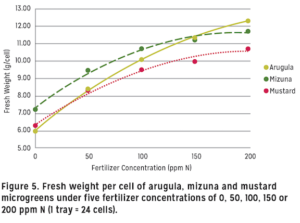

To address the question of the effects of fertility on microgreen yields, five concentrations of fertilizer solution were tested consisting of 0, 50, 100, 150 or 200 ppm of nitrogen from the complete water-soluble fertilizer (Jack’s 21-5-20).

Fresh weight of arugula, mizuna and mustard increased as fertilizer concentration increased from 0- to 200-ppm nitrogen (Figure 5). This was most apparent in arugula which exhibited an increase in fresh weight of 106 percent compared to mizuna’s 70 percent increase as fertilizer increased from 0- to 200-ppm nitrogen. Although fresh weight was greatest for all species at 200-ppm nitrogen, plants were more susceptible to lodging during irrigations and at harvest which resulted in entanglement and damage to the cotyledons (Figure 6).

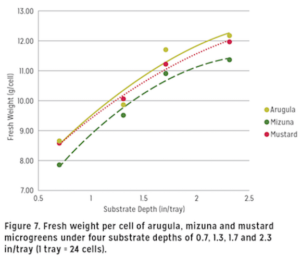

Substrate depth (i.e., root volume) impacts both physical properties (moisture holding capacity and air porosity) as well as total nutrient availability. For the cultivation of microgreens, it is very common to find growers using shallow layers of substrate in containers with the goal of reducing media costs. However, this could reduce media air porosity and require more frequent need for watering/fertilization.

Four substrate depths of 0.7, 1.3, 1.7 and 2.3 in/tray (where the tallest substrate height refers to filling a tray to the top with substrate) were tested. The fresh weight for arugula, mizuna and mustard increased by 41, 45 and 40 percent as substrate depth increased from 0.7 to 2.3 inches with no significant difference between species (Figure 7).

For all treatments, an excess or deficiency in moisture content by treatment was observed depending on substrate height. For example, cells at a substrate height of 0.7 inches dried out more frequently and needed more frequent irrigation than the 2.3 inch treatment which exhibited excess moisture and the occurrence of disease pressure especially in arugula. This suggests a media height of 1.7 inches may be an appropriate balance between holding moisture and not being too wet. Alternatively, growers would need to adjust timing of irrigation to match the substrate and substrate depth. The extent of the distribution of media depth is shown in Figure 8.

Similar to seed density, seed company recommendations for germination and growing temperatures are not species specific. For example, Johnny’s Seeds recommends 75° F for germination and 61° F from germination until harvest.

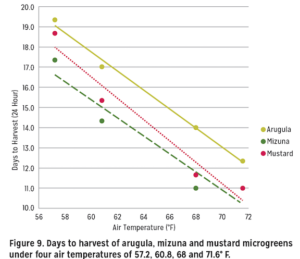

Selecting an optimal temperature can significantly reduce the number of days from seeding to harvest, resulting in several more crop rotations per year compared to suboptimal temperatures. For growers with a variety of temperature ranges, microgreens can be placed in the most compatible greenhouse.

In contrast, growers with unused bench space can compare the costs of heating at an optimal temperature for maximum crop rotation to the costs of reduced heating but longer crop cycles. This study investigated the effects of four average daily air temperatures of 57, 61, 68 and 72° F (± 2° F) on microgreen days to harvest. Increasing air temperature was linked to reduced days to harvest for all species (Figure 9). The number of days from seeding to harvest for arugula decreased by an average of seven days from 19 to 12 days as temperatures increased from 57 to 72° F. Mizuna crop length decreased by an average of 6 days while mustard decreased by an average of 8 days from a starting point of 17 and 19 days, respectively, as temperatures increased from 57 to 72° F. Overall lower temperature treatments had a significantly longer days to harvest, which was due to a slower development rate.

In contrast, growers with unused bench space can compare the costs of heating at an optimal temperature for maximum crop rotation to the costs of reduced heating but longer crop cycles. This study investigated the effects of four average daily air temperatures of 57, 61, 68 and 72° F (± 2° F) on microgreen days to harvest. Increasing air temperature was linked to reduced days to harvest for all species (Figure 9). The number of days from seeding to harvest for arugula decreased by an average of seven days from 19 to 12 days as temperatures increased from 57 to 72° F. Mizuna crop length decreased by an average of 6 days while mustard decreased by an average of 8 days from a starting point of 17 and 19 days, respectively, as temperatures increased from 57 to 72° F. Overall lower temperature treatments had a significantly longer days to harvest, which was due to a slower development rate.

Variations in the cultural practices associated with the cultivation of microgreens can have a significant effect on crop yield, harvest time and crop quality. Through the modification of the growing environment for seed density, fertilizer concentration, substrate depth and air temperature, growers can maximize yield, minimize production time and achieve a target crop size based on individual market demand.

In conclusion, based on our findings, initial parameters might be to sow seed at a rate of 18 seeds per in2 over a peat-lite media at a height of 1.7 in, fertilized with a complete liquid feed fertilizer at a rate of 150-ppm nitrogen and grown in a greenhouse with an average daily temperature of 72° F. As a grower, these values can be used as guidelines to help in the decision making process and starting points for the investigation of further cultivars.

Video Library

Video Library