Plant Lighting Efficiency and Efficacy: μmols per joule

Plant lighting continues to be a hot topic, especially as light-emitting diode (LED) technology continues to advance. Growers commonly ask which type of lighting technology to purchase. Supplemental lighting using LEDs is usually more efficient, but the initial cost is higher than with high-pressure sodium (HPS) technology.

The choice of lamp types involves multiple factors:

- Hours per year of lamp operation

- Cost of electricity

- Cost to purchase, install and maintain the lamps

- Possible cost of additional electrical capacity for some lamp options

- Rebates available for upgrading to more efficient lighting

- Electrical efficiency (efficacy) of each lamp type

The choice of lighting technology should primarily (but not exclusively) be based on economics. How long will it take for the energy savings to pay for the new lighting system? The answer varies among facilities.

An informed decision relies on understanding plant lighting efficacy (efficiency). Efficiency and efficacy can be used interchangeably for most purposes but, technically speaking, efficiency is used only when the units in the numerator and denominator are the same, and it is thus possible to have 100 percent efficiency.

When the output (numerator) has a different unit than the input (denominator) the ratio is called efficacy. It does not make sense to talk about the efficiency of spraying a plant growth regulator, but we can measure the reduction in plant height and divide by the amount of chemical required to determine the efficacy of the treatment. The values for lighting have different input and output units, so the appropriate term is lighting efficacy.

Until recently, the efficacy of all electrical lighting products was based on human perception of light, which is strongly weighted toward green light. Human lighting is measured as luminous efficacy and has units of lumens per watt (the number of lumens produced per watt of energy consumed). In contrast, photons with wavelengths between 400 and 700 nm (referred to as photosynthetically active radiation, or PAR) drive photosynthesis, so the luminous efficacy metric is not appropriate for plant applications.

The appropriate metric for plant lighting is photosynthetic photon efficacy (PPE). This is the PAR photon output (unit of micromoles per second, or μmol·s–¹) divided by the input power (watts, or W) to produce that light. Thus, the unit becomes μmol·s–¹·W–¹, and because one watt (W) equals one joule per second (J·s–¹), the ratio can be simplified to μmol·J–¹ (μmol per second/joule per second).

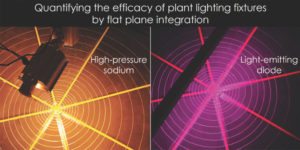

The total output of a lamp can be measured by either flat plane integration (Figure 1) or by an integrating sphere, which is a hollow sphere that is covered with a white, highly reflective coating inside to reflect light. A lamp is inserted, and light output and the electrical input (including any ballast) are measured. An integrating sphere is expensive to purchase and requires expertise to operate and thus, these measurements are regularly done by independent lighting laboratories and lighting companies.

A 400-W single-ended high-pressure sodium lamp (HPS) with a magnetic ballast has a PPE value of approximately 0.9 μmol·J–¹ while a double-ended 1,000-W HPS lamp with an electronic ballast has a PPE of around 1.7 μmol·J–¹. The value for LED products ranges considerably, and many new fixtures now exceed 2.0 μmol·J–¹. The higher the PPE value, the more effective it is at converting electricity into photosynthetic photons.

The PPE of LEDs continues to increase and purchase costs are decreasing, so some growers are hesitant to invest. The theoretical maximum PPE for LEDs is 4.6 to 5.1 μmol·J–¹, depending on the composition of the LEDs used in an array. We are unlikely to achieve these values in our lifetimes, but an efficacy of 3.5 μmol·J–¹ is possible in the next decade.

We do not recommend waiting for better technology. Many growers still operate old, dirty, 400-W HPS lamps, and upgrading to modern lighting technology can reduce electric cost by more than 50 percent. Growers who operate lamps for more than 4 months of the year (2,000 hours or more) and whose electricity prices are above average ($0.12 kWh) could realize payback in two to three years — especially if energy rebates are available. Perform your own case- specific economic analysis to help you decide what lamp type is the best investment.

Video Library

Video Library