Preconditioning Wood Substrates for Greenhouse Crop Production

The use of wood products in soilless greenhouse substrates continues to increase in popularity and demand around the globe. As more research is conducted and reported, we are learning more about the performance, potential, and possible pitfalls of using different wood products as well as higher ratios of them in our mixes. As growers continue to adopt (or trial) mixes with some percentage of wood in them, there are new questions always being discovered that need investigating/solving.

One such question pertaining to hammer-milled pine wood products is the potential of substrate toxicity affecting crop growth. In this article, we will highlight some of the recent efforts we have made in preconditioning fresh pine wood substrates (PTS) to mitigate toxins found in freshly harvested pine trees.

SUBSTRATE PREPARATION AND PRECONDITIONING

In August 2019, logs of freshly harvested 12-year-old de-limbed loblolly pine (Pinus taeda L.) trees were shredded in a wood shredder before being further processed in a hammer mill at the North Carolina State University Substrate Processing and Research Center (SPARC) in Raleigh, North Carolina. The fresh PTS (within three days of the trees being harvested) was preconditioned in a variety of methods to investigate potential strategies of mitigating harmful phytotoxic compounds in the fresh wood that could negatively affect plant growth if used fresh.

Researcher and grower trials have reported the stunting or severe deficiencies that can occur in young seedlings and herbaceous plugs when planted in substrates containing over 20% (by volume) fresh pine wood. Finding economical, efficient and reliable methods of removing the toxins (without composting) will provide greater confidence in the use of hammer milled wood products, which among other things can be acquired and produced at low cost and can be made by growers themselves or at numerous substrate manufacturer sites around the U.S. using the existing equipment (hammer mills) most already have.

including pine tree substrate (C), ForestGold (D) and GreenFibre (E).

Once the PTS was processed, the preconditioning treatments included oven drying the fresh wood at high temperatures (to volatilize chemicals in the wood), steaming the PTS for 30 minutes at 100° C in a soil steam cart, and soaking the PTS in hot and cold water for various lengths of time. An aged PTS treatment also was used in this trial, which was created by aging PTS produced the same way as previously described but three months earlier in May 2019 and stored outdoors in 1 ½ cubic yard totes. These PTS treatments (Figure 1C) were compared to two commercial wood substrate products currently available and used in greenhouse crop production across the U.S.; ForestGold (Pindstrup) a disc-refined wood fiber (Figure 1D), and GreenFibre (Klasmann Deilmann) an extruded wood fiber (Figure 1E).

EVALUATION TRIALS

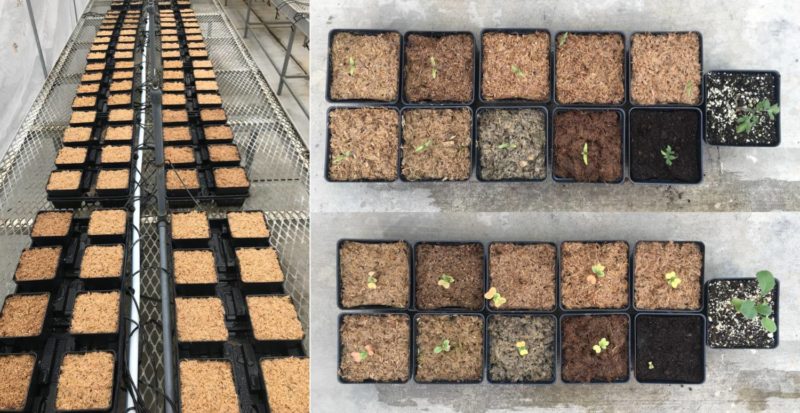

To test for substrate phytotoxicity, seedling germination and survival tests are one of the most common ways to identify the presence of plant-inhibiting toxins. Five seeds of radish (Raphanus sativus ‘Early Scarlet Globe’) and tomato (Lycopersicon esculentum ‘Better Boy’) were separately sown in 4-inch plastic containers filled uniformly with each substrate treatment and placed under mist on a greenhouse bench (Figure 2).

Two weeks after planting, the number of germinated seeds was recorded and seedlings were thinned to one plant per pot if more than one seedling was present. After two additional weeks, final seedling survival data were recorded, and seedlings were harvested. Results indicated that seed germination was not inhibited in any of the different treatments but compared to the peatlite control were smaller and discolored. Subsequent fertilization of the stunted seedlings quickly showed a reduction/reversal of symptoms but still not to the extent as the control seedlings. For the short duration of this trial, and others like it, the preconditioning treatments did show improved seedling growth compared to the fresh PTS substrate.

Poinsettias and marigolds were also grown in all wood treatments at 100% plus substrate blends which were formulated with 20% and 40% of each preconditioning treatment with peat moss (Figure 1A-B). An 80:20 peatlite substrate was used as a control treatment. These blends of 20% and 40% are more indicative of current wood component incorporation rates used in crop production.

All plants in 100% wood substrate treatments were watered by hand and fertigated with 300-ppm nitrogen (derived from a 20-10-20 fertilizer) based on previous research that showed additional nitrogen is needed for comparable plant growth to plants grown in peatlite. All plants in 20% and 40% wood products were watered by hand and fertigated at 200-ppm nitrogen. Marigolds were grown for four weeks and the poinsettias were grown for 12 weeks.

As a representation of some of the findings from these growth trails, Figure 3 shows the growth difference in poinsettia after 12 weeks across some of the treatments. Plants in 100% fresh PTS were the smallest compared to 100% oven dried PTS and the peat blends (Figure 3A). The improved plant growth in 100% PTS that had been dried support previous research trials that showed drying to be an effective method of removing wood toxins. Plants in 20% dried PTS were similar in size (mass) to the plants in the peatlite control.

When compared to the commercial wood products (Figure 3B-C), the 100% fresh PTS also grew the smallest plants which also supports previous observations that the commercial food fiber products do not contain plant growth reducing toxins due to the manufacturing processes they undergo. It is believed that the growth differences seen with the GreenFibre and the ForestGold at 100% were due to nutrition or physical properties (not toxicities) and could be overcome if managed differently.

Marigolds grown in all substrate treatments exhibited similar growth trends to the poinsettias, though not always as visually obvious (Figure 4). Plants in fresh 100% PTS were the smallest, along with the hot and cold water washed substrate treatments. Aging PTS for three months was the most effective preconditioning treatment, with plants having about a 30% increase in dry weight compared to the plants in fresh PTS. Despite differences in dry weight, plants from all treatments (including the commercial products) were of saleable quality.

The marriage of peat and wood fiber, or in some cases coconut coir and wood fiber, remains the best and most reliable option for greenhouse growers due to the familiarity and reliability that peat and coir offer. While we researchers may test and trial crop growth in 100% wood materials, that does mean it is the best scenario or recommendation to follow. Our goal is to better understand the properties of wood and ways to mitigate, manage, or alter those properties of the raw material so that when used as components in mixes, more consistency and reliability is ensured. One of the most exciting prospects of using engineered wood products (other than economics, regional availability for many consumers, sustainability, etc.,) is the uniqueness of new peat-wood, coir-wood or barkwood substrate blends that manufacturers are developing and commercializing.

Video Library

Video Library