Seeing Inside Your Container Media

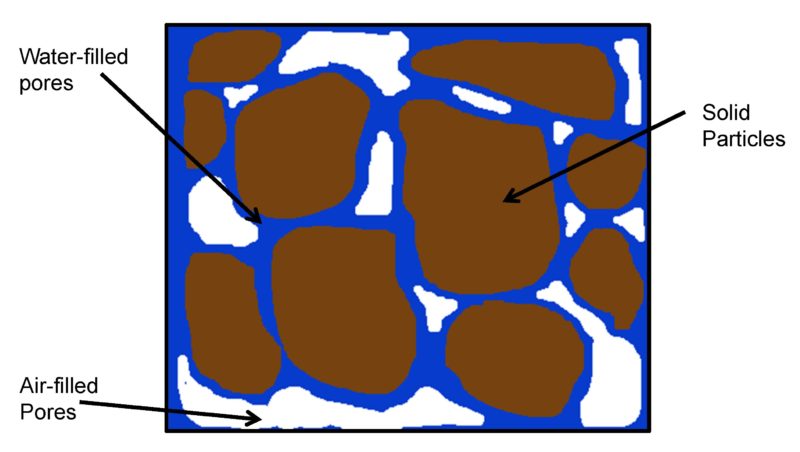

When you buy a good-quality root substrate, you are mostly purchasing holes. Solid particles from peat, bark, perlite, wood fiber and other components typically make up only about 20 to 30% of volume when a pot is filled with root substrate. The rest is made up of spaces, termed pores, which are filled with either air or water.

If we can match our irrigation practices with a substrate with adequate components and particle sizes, it results in a suitable balance of water- and air-filled pores for healthy root growth. It is difficult to visualize substrate physical properties such as porosity, but pores have a major effect on plant performance. In this article, we will try to help you see pores in a new light.

GOLDILOCKS SUBSTRATE – NOT TOO FINE, NOT TOO COARSE

If you have ever received a shipment of fine, dusty container substrate, then you may have experienced that the substrate is hard to dry down and holds excess water. This is because fine particles lead to small pores that are easily water-logged by irrigation, thereby starving plant roots of oxygen and promoting disease. For example, if a fine and compacted substrate is used in hydroponics where the substrate is continually saturated, root growth will decrease (Figure 1).

In contrast, if the substrate is very chunky, the resulting pores are large and filled with air rather than water. Use of large particles, such as the coarse perlite in Figure 2, means we can pour on water during propagation without starving roots of air, but the resulting transplant may fall apart or dry out quickly when shipped.

When we fully irrigate and drain a substrate in a pot, we refer to this level of moisture as “container capacity.” High-quality greenhouse substrates typically have water-holding capacity around 60 to 75% in a 1-liter or 1-quart container at container capacity, and air porosity in the range of 10 to 20%. To test for water and air porosity in your own substrate, go to our website (www.backpocketgrower.org) and select “Training” and “Root Substrates.” You will find porosity testing and other protocols in English and Spanish (Figure 3).

THE DIFFERENCE BETWEEN SMALL PORES AND LARGE PORES

Water adheres to the substrate particles that surround pores, because of attractive forces between both water molecules themselves, and between water and the particle surfaces (Figure 4).

At the micro-level, a root substrate contains a whole world of pores that are both large and small. You can see larger pores between peat particles in the scanning electron microscope image in Figure 5. The larger pores are likely to be filled with air. Within a peat particle, there are “internal” pores that will quickly fill with water. Internal pores may hold onto water so tightly that plant roots cannot extract it as the substrate dries (“plant-unavailable” water).

IRRIGATION’S IMPACT ON PORES

If a substrate is frequently irrigated, such as under mist propagation, it can be possible to completely saturate all pores and fill them with water. When pores are water-logged, there is no air available for root growth. That affects root growth and plant health. For example, callus can form on unrooted cuttings under high moisture conditions, as shown in the scaevola in Figure 6. However, (oxygen) to respire and grow and allowing the substrate to dry at least to container capacity is essential or rooting will be delayed.

formation but delayed rooting.

We have used X-ray computed tomography (CT) scans of mixes to see how the balance between water and air change depending on our irrigation methods and substrate choices. For example, Figure 7 shows a 50-count propagation cell of Oasis foam (bottom) with different moisture levels. We typically want at least 10% volumetric air content to provide enough gas exchange for roots to “breathe” and get the oxygen they need for growth and functioning, which means allowing the substrate to dry to less than container capacity between irrigation events.

Figure 7 shows that as the substrate dries, the pores are no longer isolated holes but form a connected pipeline which allows air exchange and oxygen supply. You can see that the bottom of the substrate is the most saturated at container capacity, because gravity pulls water down whereas capillary action draws water up against gravity. This has practical implications. For example, the water/air balance at the base of a plant cutting will depend on how deeply the sticking is placed into the propagation cell.

You can clearly see the effect of pore size on capillary action in Figure 8, where finer pores draw up water to a greater height.

DIFFERENT PARTICLE AND PORE STRUCTURES

A scanning electron image highlights the different structure of foam and rockwool (Figure 9) compared with peat in Figure 5. Oasis and rockwool do not have as many small pores as peat, have a more even range of pore sizes, and water is easily available for root uptake because water is not held as tightly as peat. This means that water and air is more evenly distributed in peat from the bottom to top of a container, whereas Oasis and rockwool have a saturated zone at the bottom of a container but have less water and more air at the top of the container.

PARTICLE AND PORE SIZE WITHIN A SUBSTRATE TYPE

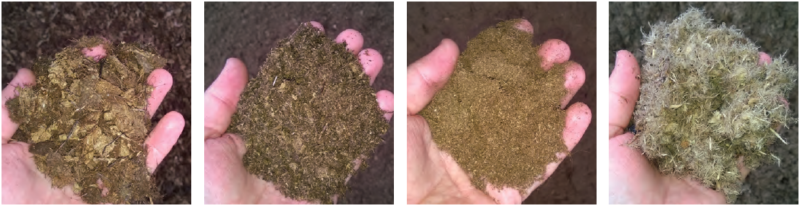

Within any component, such as peat, there can be a wide range in particle and resulting pore size (Figure 10). You may ask if adding a component such as wood fiber to your peat substrate will make it a “wetter” or “drier” mix. Figure 10 clearly shows the answer will depend on the particle size and porosity of the wood component compared with the specific peat source. Each component is like an ingredient in a pie, and you can achieve similar air and water porosity characteristics by understanding and blending the correct materials.

Acknowledgements: We thank our industry partners in the Floriculture Research Alliance (floriculturealliance.org), Specialty Crops Research Initiative, and Clean WateR3 from NIFA-USDA ARSfor supporting this research and extension program. Imaging instrumentation was provided by the University of Florida Herbert Wertheim College of Engineering’s Research Service Centers (RSC).

Video Library

Video Library