Technology — Modeling Greenhouse Energy Use

No longer the “new kid on the block,” Virtual Grower continues to provide growers the ability to model greenhouse energy use. In this free decision-support software program, first released in 2005, users build a virtual greenhouse — such as an existing structure, a planned retrofit or a new dream facility.

Based on location, heating and lighting systems selected, and desired greenhouse conditions, Virtual Grower will estimate energy usage (and costs). It includes crop models for 40 ornamentals, allowing users to identify target plant or finish dates based on selected light and temperature setpoints. Running simulations in the program allows you to experiment with a variety of “what-if” scenarios before making a final decision. Note: while it does not supplant an actual energy audit, it will estimate energy use and cost savings that may be attained by making small or large changes to your greenhouse.

Some scenarios and simulations possible with Virtual Grower include:

- compare energy costs for different greenhouse designs and materials;

- compare energy costs across multiple geographic locations;

- compare energy costs for different fuels based on current and predicted pricing;

- estimate cost savings achievable by retrofitting an existing structure with energy-efficient components;

- see the impact to crop timing and overall energy use of adding supplemental lighting;

- assist in crop scheduling by calculating a start date for a crop based on a target finish date (or vice versa), based on temperature and lighting setpoints; and

- assess carbon footprint for greenhouse energy consumption based on local electricity resource mix.

Currently, Virtual Grower is a Java-based program, compatible with Mac and PC computers, and available in three languages (English, Spanish and French). Version 3.1 is available for download at www.virtualgrower.net.

CURRENT TEAM

Our small team has grown in the past 18 months and currently consists of three individuals. Kale Harbick joined in early 2020, and his expertise in agricultural engineering and energy modeling complements Jennifer’s expertise in crop production and modeling plant responses to light and temperature. Together, they co-lead the development of Virtual Grower. Yahia Hegazy joined ARS in summer 2020 and is the software programmer for Virtual Grower.

WHAT’S NEW

In its 15-year history, Virtual Grower has undergone many iterations and advancements. What’s in store with the next version?

New interface: We are developing a web-based version that users can run on any browser without having to install any software locally. This will allow growers to seamlessly run the latest version with a simple refresh, and to store models in the cloud if desired.

Engineering/modeling updates: This will standardize energy modeling calculations according to the American Society for Heating, Refrigerating and Air-Conditioning Engineers heat balance method and improve simulation accuracy.

Expanded lighting section: First, LEDs will be included as a lighting option. Second, additional lighting programs, such as target daily light integral (DLI), will be available. This will allow you to compare lighting costs for different lighting strategies. For example, if you are lighting for supplemental and not photoperiodic purposes, you could compare no lighting versus having supplemental lights on for a set duration daily versus running lights during the day (if cloudy) and into the evening only as long as needed to attain a target DLI.

Cooling/ventilation section: A new tab will include energy use and cost estimates for fans, evaporative cooling, and ventilation. This can be considerable, especially in hotter months and locations. This will also enable estimation of sensible cooling from evapotranspiration.

Cost calculator to estimate payback periods: A new tab will enable users to input capital costs and energy prices, then calculate the cost of installing an energy-efficient upgrade (e.g., energy curtain), potential energy savings, and an estimated payback window.

Built-in language option: English, Spanish and French will be available in the same download and selectable, like units. This will let users instantaneously switch between languages, as needed, to share simulations with colleagues or a supervisor.

IMPROVING PRODUCTIVITY AND PROFITABILITY

Let’s run through two case studies.

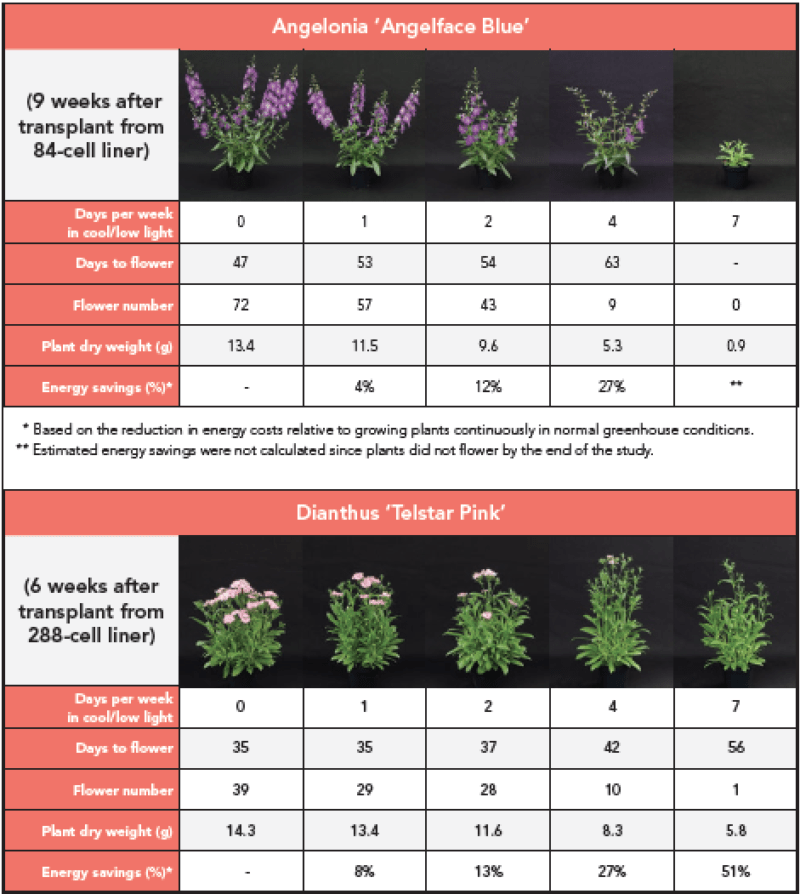

Case study #1: Growing plants at lower temperature/irradiance to save energy costs: A few years ago, we looked at the potential of growing annuals at lower than optimal temperatures and DLIs for one or multiple days per week as a potential strategy to reduce greenhouse energy costs. The working hypothesis was it should be feasible, but it would likely delay flowering. Would a longer production window increase or decrease total energy costs? The “normal” greenhouse was 72/65° F day/night, with a DLI ~15 mol·m-2·d-1 and 14 hour photoperiod. The cool/low DLI greenhouse was 55/50° F day/ night, but with a DLI ~6 mol·m-2·d-1 achieved by closing the energy curtain during the day for heat retention.

In general, “cold-sensitive” or “warm-season” crops (e.g., angelonia, lantana) experienced a delay in flowering with only one day per week in cool/low light and the other six days per week in “normal” conditions. However, “cold-insensitive” or “cool-season” crops (e.g., dianthus, pansy and petunia) could be grown two days per week in cool/low light conditions without impacting crop timing or plant quality (Figure 1).

Furthermore, they could be grown for four or even seven days per week at cool/low light if longer production times and fewer crop turns per season were not critical. For this study, we turned to Virtual Grower to calculate the projected energy savings. At our location in Toledo, Ohio, total energy savings across all crops were estimated to be roughly 10% and 25% when plants were grown two or four days per week, respectively, at cool/ low light conditions. (More details of the study are available at www.doi.org/10.21273/ HORTSCI10289-17)

Case study #2: estimating cost savings by implementing energy-efficient design elements:

Consider a new or existing “bare bones” greenhouse installation with six spans (25 x 100 feet each; 15,000 square feet total). It has a glass roof and bi-layer polycarbonate siding. Including a foam-insulated knee wall would reduce heating costs by roughly 25%. Addition of an energy curtain would further reduce energy costs by roughly 40% (depending on geographic location). Of course, the potential reduction in heating costs would need to be weighed against the cost of installation for any retrofit or upgrade, but the payoff time could range from less than a year to a couple of years (or even quicker if fuel costs increase). With Virtual Grower as your “crystal ball,” you can virtually create as many scenarios as you would like, compare them, and run cost calculations before deciding.

LOOKING FOR FEEDBACK

We would like Virtual Grower to be as useful and user-friendly as possible. Many improvements in earlier versions came from user feedback. Let us know what you like, what could be improved, or features you would like to see added. Also, please reach out if you would like to test the next version when we get closer to release.

Video Library

Video Library