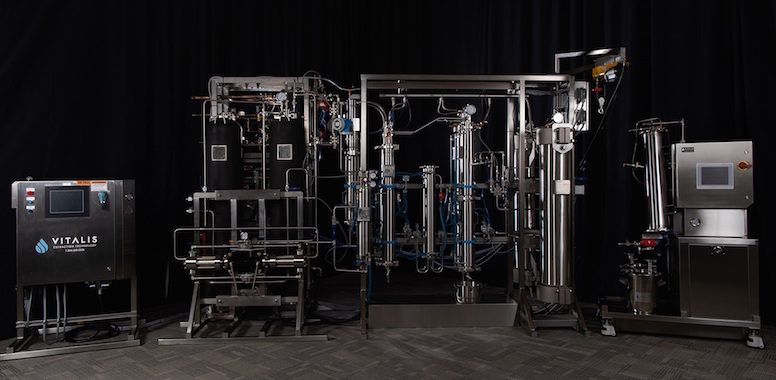

Vitalis Extraction Technology Adds Cosolvent Injection System

Vitalis Extraction Technology, Inc., a provider of CO₂ extraction solutions, has introduced its latest innovation: the Cosolvent Injection System (CIS). The patent-pending technology delivers the purities of CO₂ extraction process while leveraging the power of ethanol to significantly reduce runtime and operational costs, as well as improve post-processing.

Vitalis CIS has been designed to help companies scale their operations, by reducing their cost per gram.

“From the beginning, our innovation has been led by customer collaboration, and the launch of Vitalis CIS is no exception,” said Vitalis CEO Joel Sherlock. “The industry has matured, demand has increased, and our customers need to be able to keep pace. Backed by data from real-world application, we have developed a flexible solution for greater operational efficiency and extraction accuracy.”

The Vitalis CIS provides versatility in extraction and offers a cost-effective solution to future scaling ambitions. By injecting a controlled amount of ethanol into the CO₂ extraction process, the cosolvent system is designed to increase the extraction efficiency for hemp and cannabis processors by leveraging the benefits of CO₂ extraction (capturing terpenes, targeting desired cannabinoids, lowering operating cost) and the power of ethanol.

The novel Vitalis cosolvent option provides flexibility that extractors need to expand their operations and grow their product lines. Compared to a CO₂ extraction using conventional winterization methods, or a cold ethanol extraction, the cosolvent process significantly reduces the volume of ethanol used for each gram of oil produced. Engineered as a plug-n-play add-on rather than alteration to CO₂ extraction equipment, the Vitalis CIS design allows for continued operation of Q-series and R-series equipment for mono-solvent CO₂ processing when desired.

James Seabrook, chief technology officer and co-founder, led the team in developing the Vitalis CIS.

“We set out to create a product that would enhance the extraction process for our customers,” Seabrook. “Vitalis CIS retains the ability to capture terpenes, operate using CO₂ as a mono-solvent if desired, and remediates residual ethanol from the spent biomass as part of its standard design and operation. The system also integrates solvent management controls to automate the collection from the extractor and maintains a non-hazardous room classification. All of this while significantly increasing throughput, reducing the volume of ethanol required, and no compromise on quality.”

The development and launch of Vitalis CIS is the culmination of 12 months of intensive research and controlled real-world testing on both cannabis and hemp with the support of licensed producer partners. While differing operational variables are taken into account, the results from the implementation of the cosolvent system were consistent. Each partner saw a staggering decrease in extraction runtime, lower operating pressures, greater selectivity in the extraction process, an increase in extract quality, and utilized minimal quantities of ethanol.

“The best part is, it can be added to your existing system, with a small footprint designed to fit into any facility layout and casing created to satisfy fire regulations,” Seabrook said. “The Vitalis CIS really has been designed to deliver efficiencies at every operational level.”

The introduction of Vitalis CIS aims to best serve the company’s core customer base that includes producers of cannabis and hemp while maintaining the bar for safety, service and performance. Vitalis CIS is currently patent pending.