An Introduction to Integrated Pest Management for Indoor Hemp

Integrated pest management (IPM) is a comprehensive approach for preventing and managing insect, mite and disease pressure. When it comes to indoor hemp production, an effective IPM manager should have a clear understanding of how chemical, biological and cultural strategies can be used in combination with each other to ensure a clean operation. This article will outline fundamental characteristics of an indoor hemp IPM program centered around crop protection, sanitation and scouting for insect and mite pests.

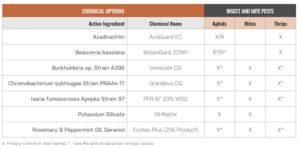

Chemical Control Options

Crop protection chemicals are a strong ally in managing pest pressure. The majority of the chemicals currently approved for hemp usage are microbial or naturally based. These are sometimes referred to as “softer chemistry” or biopesticides as compared to “harder chemistry” or synthetically derived chemicals commonly used in ornamental production. Harder chemistry products typically have longer residuals and may have systemic activity against insect and mite species; whereas softer chemistry products have fewer resistance issues and are safer to use on crops being consumed by humans.

Because hemp growers have an overall smaller chemical “toolkit,” it is important to utilize effective chemical control products based on the pests being targeted (Figure 1). The crop protection chemicals mentioned in this article were referenced from the current EPA list (as of February 2021) of pesticides

registered for use on hemp. Several states currently only allow the use of 25(b) minimum risk pesticides. It is the grower’s responsibility to follow all chemical label instructions as well as contact their state’s hemp regulatory agency to determine specific pesticide regulations for their state before making chemical applications.

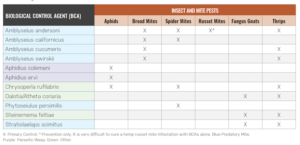

Biological Control Options

Depending on the state’s regulations, chemical crop protection options may be limited or not available altogether. Fortunately, biological control agents (BCAs) provide a desirable solution for pest control and prevention. In essence, we are fighting fire with fire by implementing insects and mites that naturally target the pests we do not want to feed on our plants. There is a wide range of BCAs on the market that can effectively control specific pests (Table 2).

Proper use of BCAs can greatly reduce or eliminate the use of pesticides, and there are even biological-based pesticides that are compatible with most BCA species. BCAs require a proactive strategy in which action is taken prior to pest presence or at the first sign of pest presence. BCAs are most successful by preventing the buildup of pest populations and can be applied to the crop in various ways (e.g., bulk releases, slow-releasing sachets, blister packs and breeder piles). It is also important to recognize that releases must be planned and executed over the entire crop cycle.

Sanitation

Sanitation should be an ongoing process both between and during crop cycles. Clear and repeatable procedures should be in place to prevent the spread of pests that become introduced and/or established during production. Since control measures are often limited during active crop production, complete sanitation between crops is one of the best protective protocols an indoor hemp producer can employ.

Choosing an effective cleaner and sanitizer as well as applying them appropriately is crucial to starting off clean between cycles. Hard surface and irrigation line sanitation between crops will drastically limit pest and disease carryover to future crops and help to limit development of algae/biofilm. Insect and mite pests look for any surfaces to cling to when their food source is being taken away such as when rooms are being emptied for harvest. During this time, thorough sanitation of benching, floors, walls, irrigation lines and any containers or other crop supports that will be reused should take place.

Scouting

Understanding the “tools” you have available, how to use them, and when to use them is only half the battle. Even with a strong IPM plan in place, a minor issue can quickly turn into a raging fire if left unchecked. This is where the importance of scouting comes into play. Daily scouting should be considered as a top priority outlined by clear standard operating procedures (SOP). Proper use of yellow sticky cards and plant inspections are critical parts of proper scouting.

Yellow Sticky Cards – Used to monitor flying insects (thrips, whitefly, fungus gnats, shore flies, winged aphids, several beneficials). Inspect, record counts and change cards on a weekly basis (mark cards with date and location when placed). Place one card per 250 to 500 square feet with the bottom third of the card in the canopy. Be sure to place cards near doors and vents. Consider horizontal card placement at 6 to 8 inches above the media to monitor for fungus gnats.

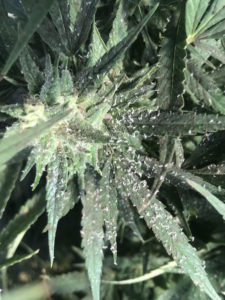

Plant Inspections – Physically inspect plants for insect and mite presence, including the presence of eggs and signs of feeding injury (including presence of honeydew and/or sooty mold). Examples of this can be seen in Figures 1 through 4. Inspect all parts of the plant, including the roots. All cultivation team members should be able to confidently identify key insect and mite pests and distinguish them from beneficials. Beat tests can also be done to check for insect and mite presence, especially for those less likely to be trapped on sticky cards (e.g., aphids, spider mites, immature thrips and beneficial mites). This involves using a piece of white paper held to a clipboard to help visualize the insects knocked off plant foliage. Hold the clipboard under the foliage and gently tap the plants to dislodge insects and mites onto the white paper.

As with any type of plant production setting, each facility is unique in how it was built, how it is managed, and the issues it experiences. An IPM manager should use a broad stroke when designing a program that works for them, but they should also be comfortable adapting and enhancing their strategy as changes within the operation occur. Detailed record keeping and active communication between team members can help in the revising your plan as needed. The word “integrated” cannot be prioritized enough when developing a sustainable IPM program, because it truly does require an integration of crop protection, sanitation and scouting knowledge to be successful.