Cannabis water use efficiency under more supplemental light

Cannabis cultivation is rapidly increasing and growers are looking into the latest research advancements and technology to boost profitability and differentiate from the competition. All this comes at a critical time when resources and their environmental impact play critical roles in agricultural products’ production and carbon and water footprint.

As the cannabis market opens in the U.S., resources such as water and energy are in higher demand to increase production and quality. However, water shortages are a growing concern in many states due to climate change, population growth and lack of infrastructure, among others. The CEA-NCSU-Coalition at North Carolina University studies how cannabis utilizes water under different lighting levels with the goal of increasing plant growth and yield with less water.

In order to achieve the ambitious goal and help growers, Professor Ricardo Hernández and Current partnered in a 3-year journey. As a leader in horticultural lighting, Current, works with some of the world’s pre-eminent horticulture research institutions to ensure its lighting technology is rooted in science and a deep understanding of plant biology.

The CEA-NCSU-Coalition specializes in Control Environment Agriculture (CEA) from speed breeding in micropropagation vessels to greenhouse and vertical farm production. As part of the team, Cristian Collado, a researcher and agronomist who specializes in indoor crop physiology, production and CEA systems, has designed and led the advanced greenhouse system and projects to produce cannabis crops under CEA conditions.

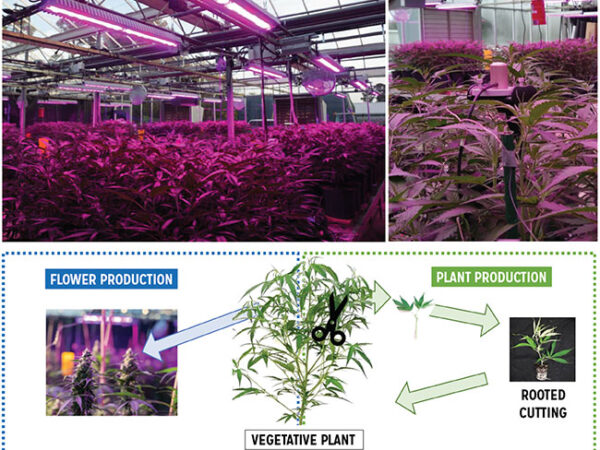

Using Current’s Arize Element L1000 LED top lighting in a greenhouse setting, we explored the impact of light levels on the production of cuttings, plant growth, flower production, quality, and water use of a Cannabis sativa variety commonly cultivated for its high levels of CBD. The impact of different levels of light throughout the vegetative and reproductive phases of growth was isolated by controlling all other environmental factors such as temperature, fertigation, CO2 and water usage.

IMPLICATIONS OF HIGHER LIGHT LEVELS, VEGETATIVE GROWTH AND WATER USE

Maximizing the number of branches and stimulating the nodal points between which cuttings can be taken is critical for nurseries whose primary goal is to produce cannabis clones for sale. In addition, increasing nodal points also increases the potential flower yield. Therefore, the vegetative yield (branching/nodal points) and water-use efficiency (branches per volume of water) in response to supplemental light intensity were studied for greenhouse cannabis.

To achieve our goal, we regulated and analyzed the quantity and demand of resources and plant growth factors on an ongoing basis. To do so, we added light and water- control and measuring capabilities to every plot in the greenhouse in addition to measuring temperature and evapotranspiration.

As shown in Figure 1, the cannabis crops were grown under four light levels using two Current’s dimmable fixtures per plot supplementing sunlight. The L1000 PPB lighting fixtures delivered uniform supplemental light intensities of 150, 300, 500, and 700 μmol m-2 s-1 for 18 hours, while the Daily Light Integral (DLI) from the sun and LEDs were on average around 18, 30, 40 and 52 mol m-2; however, we present preliminary results for the three highest light levels. Moreover, the fertigation system was triggered independently at each plot when the pots’ water container capacities were 80%. This maintained consistent water and nutrient levels in pots regardless of the crop growth rates. Finally, the water use was quantified with load cells (scales) under the plants.

IN A PREVIOUS COMMUNICATION

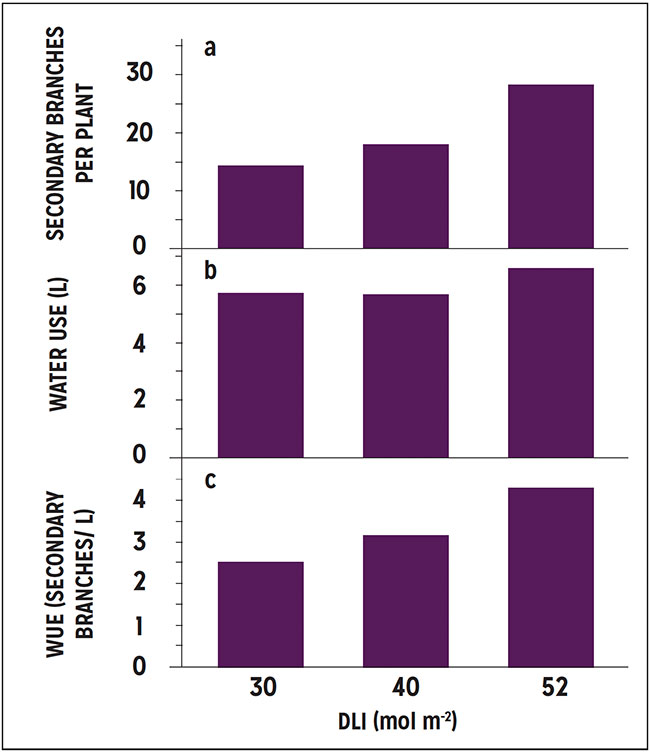

In a recent article, we showed that the light levels marginally increased the number of primary branches (the branches on the main stem). However, the light levels strongly affected the number of secondary branches (branches on the primary branches/cuttings) as shown in Figure 2a.

The results suggest that increasing the light amount, not only increased the number of branches or cuttings per plant but also could increase the water demand (Figure 2b) and water-use efficiency to produce cuttings (less water per cutting) (Figure 2b). In other words, plants grown under an average DLI of 30 mol m-2 d-1 for 21 days produced close to 29 cuttings pe plant while plants grown at 52 mol m-2 d-1 produced 47 cuttings per plant from new secondary branches. Furthermore, plants grown under 30 mol m-2 d-1 produced 2.5 cuttings per every liter of water while plants grown under 52 mol m-2 d-1 produced 4.3 cuttings per the same liter of water. This means the crops were more efficient at transforming water into branches under higher light intensities.

IMPLICATIONS FOR GROWERS

The current research highlights the ability of a cannabis crop to use higher light levels to increase yield and water- use efficiency (higher yield per liter of water). As we saw, the water-use efficiency for cutting production went from 2.5 to 4.3 cuttings per liter of evapotranspirated water when growing plants under 30 versus 52 moles of light per day, respectively. This would mean that to produce 100 cuttings using 52 moles of light, growers needed 23 liters of water instead of 40 liters under 30 moles of light.

WOULD LIGHTING BE COST-EFFECTIVE?

To answer this, we need to consider production and cost levels. A production yield of 0.37 cuttings per every mole of light was reported in our last communication (link above). Using a market value of $2 per cutting, electricity cost of $ 0.11 kW-1, L1000 HPPB efficiencies (3.1 μmol J-1), and our reported yield per light (0.37 cuttings per additional mole of light); growers can generate revenue of $0.73 from the extra cutting production and spend $0.01 on additional electricity per every mole of additional light. This suggests that providing cannabis with high supplemental light intensities is economically feasible for the cannabis nursery industry. Note: This study was conducted on one cannabis cultivar, ‘Suver Haze’, we expect all or most cultivars to increase their vegetative growth under these light levels and optimal production conditions; however, the number and rate of branches per mole of light can still be lower or higher due to genetic differences between strains.

ABOUT THE AUTHORS

Cristian E. Collado

Cristian E. Collado is an agronomist and agronomy engineer who is focused on increasing production and understanding plant and crop physiology while minimizing the environmental impact. He has developed advanced growing systems for greenhouse and indoor farm studies to improve data quality, increase plant and crop physiology knowledge, and reduce resource usage. Additionally, he has designed a vertical farm multi-crop propagation chamber used in precision propagation facilities. Since 2016, Cristian has been a valuable NC State Controlled Environment team member, coordinating CE research projects while completing his Ph.D. Cristian’s team has also been his wife, Laura, and their two young daughters, Aylen and Lucia, whom he has been proud to be a part of for over 12 years.

Cristian E. Collado is an agronomist and agronomy engineer who is focused on increasing production and understanding plant and crop physiology while minimizing the environmental impact. He has developed advanced growing systems for greenhouse and indoor farm studies to improve data quality, increase plant and crop physiology knowledge, and reduce resource usage. Additionally, he has designed a vertical farm multi-crop propagation chamber used in precision propagation facilities. Since 2016, Cristian has been a valuable NC State Controlled Environment team member, coordinating CE research projects while completing his Ph.D. Cristian’s team has also been his wife, Laura, and their two young daughters, Aylen and Lucia, whom he has been proud to be a part of for over 12 years.

Dr. Ricardo Hernández

Dr. Ricardo Hernández, an associate professor at North Carolina State University, focused on controlled environment research, specializing in optimizing environments to maximize plant responses. As the director of the CEA-Coalition at NCSU, he heads a multidisciplinary research group. Collaborating with scientists, engineers, and industry partners, their evidence- based research aims to reshape CE agricultural practices for a more sustainable future. Current CE research projects include Indoor propagation (vegetables, berries), Cannabis, Speed-breeding, Vertical farm molecular breeding, and Agrivoltaics. Beyond academia, Dr. Hernández has a doctoral training in entrepreneurship and co-founded two startups: Grafted Growers (graftedgrowers.com), specializing in vertical farm plant propagation, and Phlora (phlora.com), focused on advancing vertical farm technology development. Dr. Hernández’s work spans academia and entrepreneurship, driving innovation and sustainability in CE agriculture.

Dr. Ricardo Hernández, an associate professor at North Carolina State University, focused on controlled environment research, specializing in optimizing environments to maximize plant responses. As the director of the CEA-Coalition at NCSU, he heads a multidisciplinary research group. Collaborating with scientists, engineers, and industry partners, their evidence- based research aims to reshape CE agricultural practices for a more sustainable future. Current CE research projects include Indoor propagation (vegetables, berries), Cannabis, Speed-breeding, Vertical farm molecular breeding, and Agrivoltaics. Beyond academia, Dr. Hernández has a doctoral training in entrepreneurship and co-founded two startups: Grafted Growers (graftedgrowers.com), specializing in vertical farm plant propagation, and Phlora (phlora.com), focused on advancing vertical farm technology development. Dr. Hernández’s work spans academia and entrepreneurship, driving innovation and sustainability in CE agriculture.