Cover Story — Innovation in Action

Efficiency, plant quality and profitability. These are some top priorities of every grower. They roll right off the tongue, but are they easy to achieve?

Maybe … if you put in the upfront effort. Big Grower is on a mission to find out what the most efficient operations are doing to maintain smooth-running facilities while producing the best plants profitably.

We sat down with a few of the country’s top growers to learn about what processes and innovations they’ve recently implemented in their operations to help them save dollars and improve production. From software to lighting and everything in between, every grower is different. What works for one may not work for the other. But we discovered various ways that these growers are boosting their bottom line. Read on. Maybe one of these methods will work for you!

DIRECT STICKING AT DUTCH HERITAGE GARDENS

Labor. It’s a dreaded source of stress for almost any large grower. Whether it’s finding skilled labor or being able to afford a fair wage or anything in between, labor is one of the issues that is a constant hurdle.

Three years ago, management at Dutch Heritage Gardens (Larkspur, Colorado) expected they would be down on labor, so they began exploring ways to work around this challenge.

“It’s not that we were looking to cut labor,” says Brian Austin, head grower. “It was just an adjustment we needed because it’s very hard for us to find labor where we are located.”

“It’s not that we were looking to cut labor,” says Brian Austin, head grower. “It was just an adjustment we needed because it’s very hard for us to find labor where we are located.”

According to Austin, the team started putting together ideas they thought might help. They borrowed an idea from another large grower that was direct sticking cuttings into finished containers.

“Growers have been direct sticking poinsettias forever,” says Austin. “And they’re not exactly the easiest plants to grow.” So he asked himself, “Why aren’t we direct sticking an easy crop, like petunias?”

He also factored in the way multi-liner combinations are created. “With Confetti liners, you’ve got three different genuses stuck together in an Ellepot,” explains Austin. “So we figured we could take that same concept, and now our Ellepot becomes a 10-inch basket. We’re sticking them together but in the final container.”

So, three years ago, the grower began a trial with direct sticking. There was no limitation on crop type. Dutch Heritage Gardens grows pretty much everything, from petunias and osteospermums to perennials to poinsettias and mums. The trial was successful, so the next year they amped it up to about 50 percent of their production. The results were again quite encouraging and so this past season they went up to about 65 percent of their production, which is about as much as they can do because of space limitation.

By choosing to skip that early liner stage, the grower saves four or five weeks on crop time, says Austin. And they were subsequently able to save on labor by not having to transplant anymore.

“You’re always going to have to stick the cutting anyway, so that labor is always going to be there, whether it be in an Ellepot, a liner or in a finished container. But this is just pure, time saving and labor saving with skipping an entire process,” says Austin.

What does skipping this process really amount to? Well, three years ago, Dutch Heritage grew a certain amount of product with 120 people. “Now three years later, by doing direct stick, we grow the same — maybe even a little more — product with 90 people. So it saved us 25 percent in labor,” shares Austin.

Along with the quick crop times, they were also able to grow more crops. Austin says they were able to achieve an extra turn or half a turn of the entire space. An example: A calibrachoa quart would typically take, from cutting to out the door, about 11 weeks. That’s four weeks in a liner and seven weeks to finish. “Now sticking that cutting right in the finish container, we are shaving off four weeks. So it’s seven weeks from stick to ship. We just bought ourselves four more weeks in the spring to grow another crop,” explains Austin.

Everything isn’t perfect, and there is a minor drawback to the process. According to Austin, this system is space limited. “We always run into that bottleneck in the middle of spring. So while we have the available space, we direct stick as much as we can and we fill up the space as fast as we can, but there’s a point for us around week 16 where we have to go back to the traditional method of liners just because it condenses that large plant amount into a smaller space.”

And once they ship that product out, they create more space and go right back to direct sticking.

While Dutch Heritage Gardens has reached it’s max with direct sticking, they are exploring ways to make the process even more efficient. Stay tuned!

ROBOTICS AT FOUR STAR GREENHOUSE

When it comes to sticking millions of cuttings, labor costs and product quality are major challenges. To combat these challenges, Four Star Greenhouse (Carleton, Michigan) is using automated sticking machines to not only save on labor but also to maintain (and improve on) the quality of its Proven Winners products.

The team at Four Star needed a solution that would help offset these challenges, so the company purchased two ISO 2500 robotic sticking machines (pictured above) in 2016 from the ISO Group in the Netherlands. After the success of the first two machines, a third one was purchased in October 2017.

“We stick over 50 million cuttings a year. We have the ability to run the ISO machines 24 hours a day five to six days days a week during our peak production season,” says Jeff Back, Four Star’s director of greenhouse operations. “This is a very labor intensive job, and our products have short windows to be produced. This requires us to bring around 180 extra employees into our production department between December and March.”

The ISO machines stick every cutting to the same depth which provides product uniformity. They have self-learning vision software, so different cutting types can be planted in a short time. The user-friendly interface ensures the easy and fast input of new plants.

“The ISO machines are great in that we have the ability to program every individual genera and variety into the control system, which allows us to stick a wide range of cuttings with a high degree of accuracy,” Back says.

Each robotic sticking machine can stick approximately 2,400 cuttings per hour. Not only do the machines do the physical work, they also provide critical data to help analyze cutting quality and process efficiency.

“We were very excited to see how well the [ISO] control systems integrated with our computer system. This was a huge advantage in helping us fully automate the sticking line front to back,” states Back.

“With their computer system integrated into our production software, we are still able to do our product verification, labeling, lot tracking, location tracking and all of the steps we do with manual sticking but the machines control all of it with only two operators. With so few operators needed, it is easy to find folks who are willing to work each shift needed during our busy season. Each machine does the work of 2.5 to 2.75 people. This does not sound like much until you figure in running the machines 24 hours. This is where you really start to make up labor hours,” Back remarks.

Four Star also worked with ISO to add in the ability to disinfect the robot gripper to help meet its strict sanitation guidelines. The two companies also worked together to integrate a way to add rooting hormone into the automated sticking process — eliminating another manual task.

According to Back, the production team is always trying to find ways to utilize the ISO line (currently made up of the three units) beyond their peak season to help offset sticking labor.

He says that this past September they were already programming all of their new varieties into the machines for the 2019 season. “Our goal will be sticking a minimum of 20 percent of our total production on the ISO line.”

Four Star continues to look for innovative ways to cost effectively grow high quality plants. Last month, Four Star was scheduled to install another robotic transplanter — a Visser Autostix machine — to help out with their workload using the biodegradable cutting strip system.

Back says the plan is to run the AutoStix machine 24 hours a day during peak season along with the ISO line. The goal is “to continue to offset our seasonal labor demands and allow our full-time employees to focus on other labor intense processes such as topcutting, quality assurance and maintaining our high product quality standards.”

You can view a video of Four Star’s ISO 2500 machines in action at https://pwfourstar.com/ resources/video-library#20170110-robotic-sticking.

LED LIGHTING AT IWASAKI BROS.

Over the past five or so years, LED lighting has become increasingly appealing to growers. With researchers, like Erik Runkle from Michigan State University, performing trials with successful results, LEDs are hard to ignore.

While obtaining efficient amounts of lighting is a challenge for almost any grower, it’s an even bigger issue when you’re located in the dreary Pacific Northwest like Iwasaki Bros. (Hillsboro, Oregon).

Three years ago, Iwasaki Bros. was using high-pressure sodium (HPS) lights throughout its 17 acres of greenhouses. “Fifteen years ago, they were cutting edge,” says Kathleen Baughman, operations manager. “But they do use so much energy. And they’re hot.”

Three years ago, Iwasaki Bros. was using high-pressure sodium (HPS) lights throughout its 17 acres of greenhouses. “Fifteen years ago, they were cutting edge,” says Kathleen Baughman, operations manager. “But they do use so much energy. And they’re hot.”

“And what’s really hard for us is Mother’s Day,” shares Boughman. “We have to start everything in December or January. So not only is it kind of dark here anyway comparatively, but then we’re starting the majority of our crops in the darkest time of the year.”

The HPS lights were helping, but all the research was pointing out that at least 10 mols of light per day of accumulated light is what will build the best quality cutting, says Baughman. So as Jim Iwasaki, owner, continued doing more and more research into available lighting options and trials, he pushed for the company to figure out a new plan for lighting.

Iwasaki asked Baughman to set up a four-way trial between the HPS lights and various types of LED lights in their seed range. She says the big take-home message was plants really like light! And the results were majorly in favor of Philips (now named Signify) LED lighting.

“What used to happen before is we would get a lot of top burn on the plants,” says Baughman. “The leaves were bigger, and they were kind of expanding and trying to capture as much light as they could. You would look at the top and there would be a lot of growth in the plug trays. But if you checked to see if it was ready for transplant, the roots would not be there yet. And there was a lot of PGR application until the roots caught up.”

Once the plants received the appropriate spectrum of light through LEDs, the grower was able to almost eliminate the use of PGRs completely in the seeding range. “The plants are just more compact, and the root growth is really strong,” says Baughman.

With a slam dunk in the seed range, the following year, they went all in with the LED lighting and redid their unrooted cutting range the following season. And that’s where they saw even more success.

“That cut down the rooting time, in some cases, in half,” shares Baughman. “It easily took off a week, sometimes two. And in a few instances, three weeks.”

With unrooted cuttings, Iwasaki Bros. is typically growing specialty items like premium annuals and unusual petunias. So those crops get started even earlier than seed. “I think our biggest stick week on unrooted cuttings is week 1 or week 2,” says Baughman. “So the lighting absolutely helps because all of that stuff is being rooted at the darkest time of the year.”

With a successful trial in the seed range and new installations in the unrooted cutting range, this past season Iwasaki Bros. went ahead and installed LEDs in a portion of the seed range. “The biggest thing there is the quality of the cutting, says Baughman. “It makes the cutting more stacked. So, you get more nodes and a more shapely plant at finish.”

An added bonus: Because of the energy savings gained through LED lighting, Iwasaki Bros. was able save on the total investment by partnering with Energy Trust Oregon.

“The rebates offered are more attractive if you already have HPS lights because you can demonstrate how much less electricity you will use,” explains Baughman. “When we did our last installation this last spring, they paid for half of it.”

A few things to keep in mind for other growers looking to transition to LED lighting: It does affect your timing. “That first year with the unrooted cuttings, we were completely surprised by how much faster the calibrachoa was rooting. And that is a plant that does not like being root bound. It will decline quickly if it sits too long in the plug tray.”

Another thing they realized was how much the new lighting affected their feeding regimen. “It’s really hard to think about applying 200 parts per million of fertilizer in February, and that’s just not something we used to do,” says Baughman. “You bump it up, and they’d still be hungry!”

However, those minor drawbacks have proven to be worth it to Iwasaki Bros. And they plan to continue exploring ways to improve their lighting capabilities going forward.

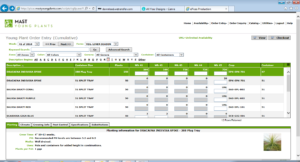

PRODUCTION SOFTWARE AT MAST YOUNG PLANTS

Finding the right software to manage your greenhouse and business operations is vital to the overall health of a grower. “It’s the lifeblood or heartbeat of our operation.” That’s how Brian Weesies, general manager of Mast Young Plants (Grand Rapids, Michigan), refers to Picas software that helps keep the company on track all of the time.

The software from Innovative Software Solutions has many core modules, each one focusing on a different aspect of the business. Growers can work with ISS to come up with the right modules and applications for their specific needs.

“Picas ultimately drives everything we do in the young plant business,” Weesies says.

Here are just a few of the things the software helps MYP do: be more efficient in ordering cuttings; double check order accuracy; and keep everyone informed on what is growing at any minute and where in the greenhouse it can be located.

Weesies says the software also can generate reports so they can supply MYP’s sales reps with accurate information on how their booking season is going and prompt them on which customers still need to be booked.

It also provides detailed information so MYP can provide its cutting suppliers with data on what is selling or which items are up or down in sales.

The software also eliminates miscommunication between people and machines. “It allows us to do a significant amount of business-to-business (B2B) or machine-to-machine [communication] which cuts down on human touches and delays,” Weesies says.

The software also eliminates miscommunication between people and machines. “It allows us to do a significant amount of business-to-business (B2B) or machine-to-machine [communication] which cuts down on human touches and delays,” Weesies says.

Weesies also likes the collaboration that MYP has with ISS. Picas offers customers a specific number of development hours each year. “Throughout the year, we log an incident report to note any changes or enhancements we would like added to Picas. Then after the spring rush is over, they will tell us how many development hours we have and send us the list of projects we identified and ask if we have anything to add to the list.

“Then they assign how many hours of development these enhancements will take and let us choose cafeteria style which ones are most important and fit into our hours. Through the years, we have created reports that were truly a wish list idea that became reality and then became very useful.”

Another benefit that MYP experienced over the past five years is changing to a direct business-to-business communication system to purchase cuttings. In years past, all cuttings were purchased by a purchasing manager who manually reviewed each line item in the MYP program each week to monitor how many cuttings were booked versus how many the customer service department had put on orders. This was a very laborious process and often required two people to manage the 1,200 varieties to ensure that enough cuttings had been purchased.

“Once we changed to B2B, our system is linked directly to the cutting farms availability. It then takes into account our grow time in the liners and translates their cutting availability into our rooted liner availability some weeks later (5 week grow time then URC availability week 5 shows up as rooted liner availability week 10),” Weesies states. “This allows MYP customer service to keep booking orders without fear that they are overbooking the URCs purchased. They can clearly see if cuttings are available or not as what is showing on their screen translates right back to the true farm URC availability.”

MYP will continue to work with ISS to develop the solutions it needs for its operations. “Right now, our future plans are to keep using the development hours to improve how the system works for our users. Each year we feel like the improvements that are done truly make the next year run more smoothly.”

Picas has been around for a while and continues to evolve for its users — something Weesies appreciates. “With Picas, we feel that it is truly a relationship where we are both working to make the other one better,” he says. “We have found a technology that is standing the test of time and getting better with age, like a fine wine.”

Video Library

Video Library