Growing from the Ground Up: Poinsettia and Mum Production in Wood Substrates

Confidence in the utilization of wood substrate components has increased since their introduction to growers in the U.S. in 2004. The confidence that some growers and other industry partners have in the evolving world of wood in growing media comes after many years of public and private research trials and testimonials. To get to where we are today in our understanding of wood substrates, there have been some bumps along the way, including occurrences of poor/failed crop growth, issues with pH and nutrient tie-up, growth stunting due to toxicities, and irrigation management struggles, among others. Over time, research has found solutions to many of these issues and significant problems are not being reported as often by growers who have adapted their growing practices to best manage crops grown in substrates containing some percentage of wood.

EARLY TRIALS

From 2004 to 2012, researchers across the U.S. did a lot of work on developing, understanding, and trialing hammer-milled pine wood materials. These included pine tree substrates (PTS), WholeTree, clean chip residual (CCR) and pine wood chips (PWC), among others. During this time, researchers were investigating the feasibility of using these hammer-milled pine materials at high rates, including substrates composed of 100% processed wood. During this “heyday” in wood substrate research a lot was understood about the limitations and potential benefits of them being used in greenhouse substrates.

Multiple trials with poinsettia as the model crop were published that showed successful crop growth in numerous container sizes ranging from 5-inch to 10-gallon (Figure 1). Trials on poinsettias grown in 100% PTS (in 6-inch pots) showed that plant shoot growth, flower timing and quality, and post production days (time) to wilt in an indoor environment could be similar to plants grown in 80:20 peatlite if 1) plants were fertigated with an additional 100-ppm nitrogen, 2) particle size of the PTS was reduced to have similar water holding capacities, or if 3) 25% peat moss was blended with the PTS.

Early fertility trials were also published showing that 100 ppm additional nitrogen was needed for chrysanthemum’s grown in 100% PTS to be comparable to plants grown in a peatlite control. These, as well as many other published works offered a foundation of knowledge about what was needed to be able to successfully grow greenhouse crops in wood substrates. Since these early years of evaluating 100% wood substrates, more emphasis has been placed on using wood in smaller percentages with peat moss to mitigate the challenges that 100% wood posed.

Additionally, there are advantages of the peat moss itself that made crop production easier and crop management more reliable for growers. Since about 2013, the majority of research emphasis and grower trials have been conducted with 20 to 40% wood as an amendment to peat. These formulations have been more readily adaptable to current growing conditions, with few if any management changes needed.

Also since 2013, several commercial wood fiber products have been introduced on the market from companies that use different machines and processing technologies to engineer very unique wood fiber materials that differ from the hammer-milled materials we had been working with. With the introduction of these commercial wood fibers, much of what we knew about wood substrates (PTS) and growing crops in them had to be re-evaluated or changed completely.

Today, research continues to support efforts to better characterize and understand these materials as well as investigate solutions to production problems and opportunities for substrate manufacturers to formulate novel, highly functioning substrates based on the marriage of traditional materials with wood products.

FOCUSING ON MUMS AND POINSETTIAS

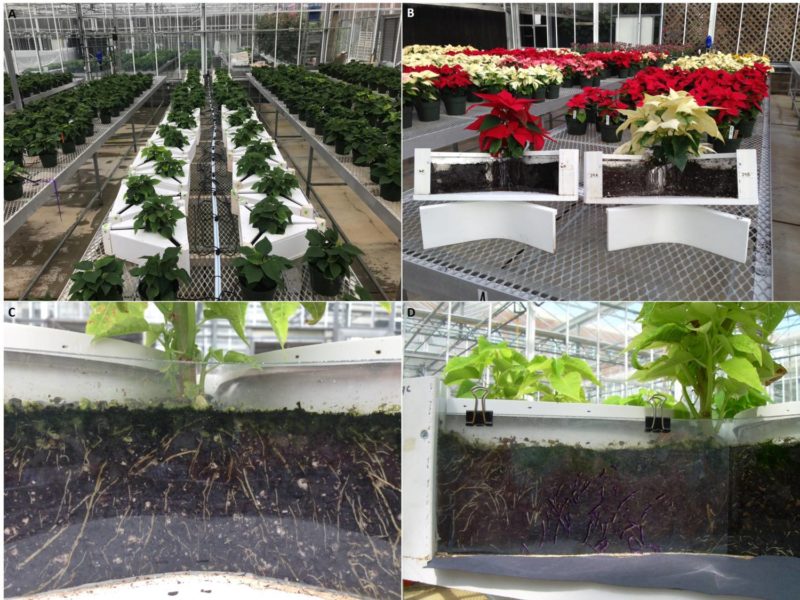

Of the many areas of needed and on-going research in the realm of substrate science, one area of recent work conducted by the Horticultural Substrates Lab and North Carolina State University has focused on understanding and quantifying the root growth of mum (Figure 2, page 24) and poinsettia (Figure 3, page 25) cultivars and the effect that wood substrates have one them. To investigate the effect wood components have on rooting and root growth, trials have been conducted in the summer/fall of 2017, 2018, and 2019 to evaluate peat moss amended with numerous North American and European commercial wood products, including freshly processed hammer-milled PTS, extruded GreenFibre (Klasmann), and disc-refined ForestGold (Pindstrup) at various rates (between 10 and 50%). Each of these specific wood materials represent different processing technologies which result in different particle characteristics (as well as some chemical differences) and substrate formulation properties. Several other commercial products of each of the manufacturing methods were also evaluated for comparison.

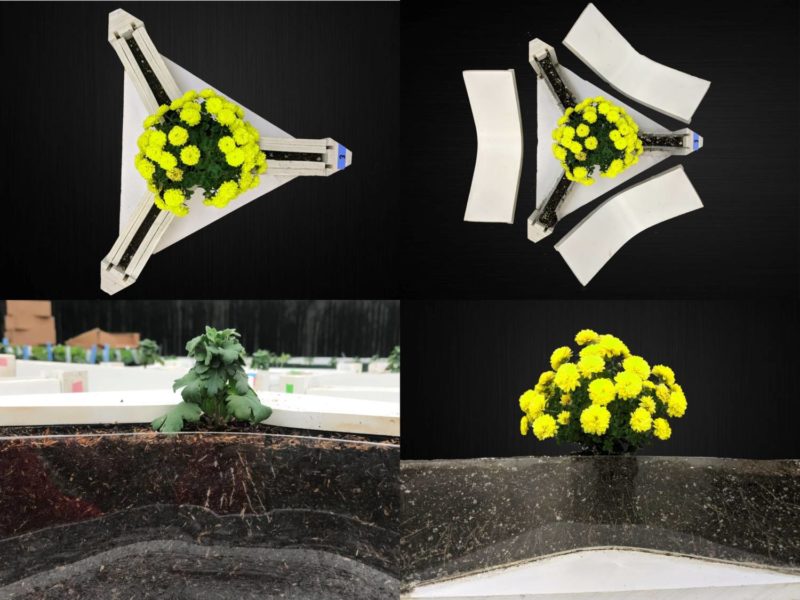

The Mini-Horhizotron was used in some of these growth trials as a tool to visually (qualitatively) and quantitatively assess root initiation, speed, branching/diameter, overall development, and health over time. Based on the design of this chamber, root initiation from stuck cuttings all the way through several weeks of growth (until roots reach the end of the arms) can be assessed.

Data can be collected by counting and measuring roots along the surface as they appear/emerge and/or by tracing roots over time (Figure 3 C and D, page 25) and analyzing the tracings to convert to total root length. In many trials with mum and poinsettia cuttings we have observed root initiation to be accelerated with increasing percentages of wood fiber in peat substrates, up to about 50%. While this (cutting propagation) needs much more investigation, our results were attributed to the increased humidity found in the more porous matrix (spaces between particles) that substrates comprised of wood fiber have as a result of the physical nature and interaction of peat and wood fibers.

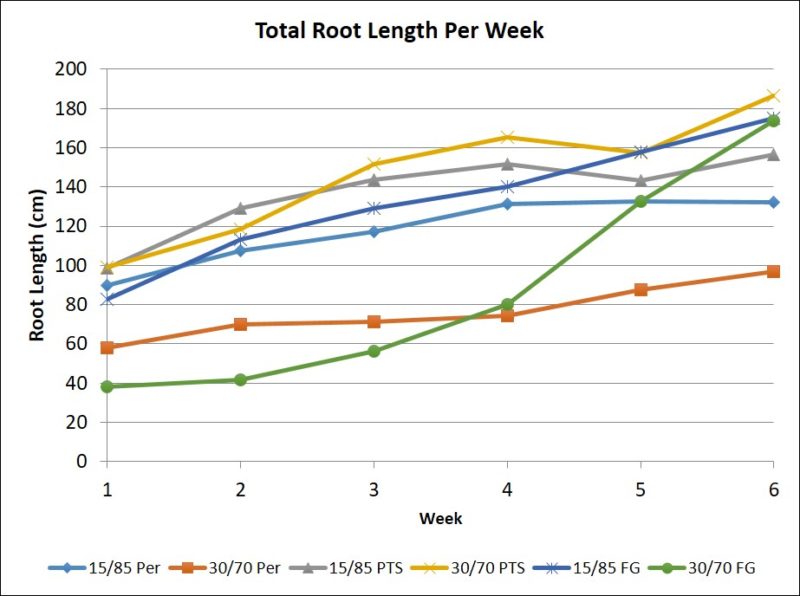

Cultivar trials of mums and poinsettia also have shown similar trends across years, that certain percentages of wood products enhance the speed of root growth during the first several (five or six) weeks of production. As seen in Figure 4 (page 25), root growth of poinsettia (‘Astro Red’) was initially accelerated in substrates containing PTS (15 or 30%) but overall growth was similar to 15% perlite and ForestGold treatments. The higher amendments of 30% perlite and ForestGold had the least amount of total root growth through the first month of the study. Overall, data from these trials provide evidence that the rooting and root growth of mums and poinsettias are as good or sometimes enhanced by wood products compared to perlite, until the percent wood inclusion gets too high, which changes the physical environment that is optimal for rooting (not a toxicity or nutrient deficiency issue).

The future role of wood products as substrate materials will continue to rely on their consistency, availability, performance and cost. At present, the main driving forces leading the surge in the national (and international) use of these materials stems from their cost and performance compared to traditional materials. Continued research and awareness now and in the future must remain focused on identifying and addressing (if possible) any associated threats or issues when using forest/wood resources for the production of ornamental and consumable crops.

Video Library

Video Library