Take Control of Managing Your Inventory

Many challenges come with managing production. Predicting demand, accounting for losses, ordering the right number of materials, managing seasonal workers and tracking inventory are some that probably sound familiar.

Running your complex business with simple spreadsheets is no longer the best option, says Ali Al-Abbasi, business development director at Argos Software. Production management software can enable growers to track material and labor costs in detail, with built-in analytics for improved forecasting. A modular and flexible software solution can be used by today’s growers to manage orders, personnel, delivery fleets, farm equipment and more, he says.

Sharon Nuss, CEO of Starcom Computer Corp., says focusing on having accurate inventory numbers is the best way to reach efficiency, with sales and the production process coming in second place. “Controlling inventory can feel like trying to hold onto a fistful of sand at the beach,” says Nuss. When she asked a business owner why they initially hesitated to fully implement an inventory software system, the response was, “We just never really believed it would make that much of a difference. Once we fully committed to doing it, we learned how important it is.”

DEALING WITH NEW PROBLEMS

Today, growers are faced with higher prices everywhere; shipping and fuel, raw materials, labor costs, and supplies have all increased. Al-Abbasi agrees that inflation is impacting demand as customers don’t have as much money to spend at the garden center, resulting in many large retailers dramatically cutting orders for plants.

Furthermore, he says some growers’ customers are moving to a “pay by scan” model, which only pays the grower once the retailer’s customer buys the product. This transfers most of the risk onto the grower; if there are poor sales from bad weather or sudden downturns in the economy, products often must be thrown out at a total loss, says Al-Abbasi.

“This makes it vitally important for growers to know their actual costs, not in aggregate but on a per item basis. For this reason, cost accounting can be extremely helpful in analyzing costs associated with running the business and finding areas to save.”

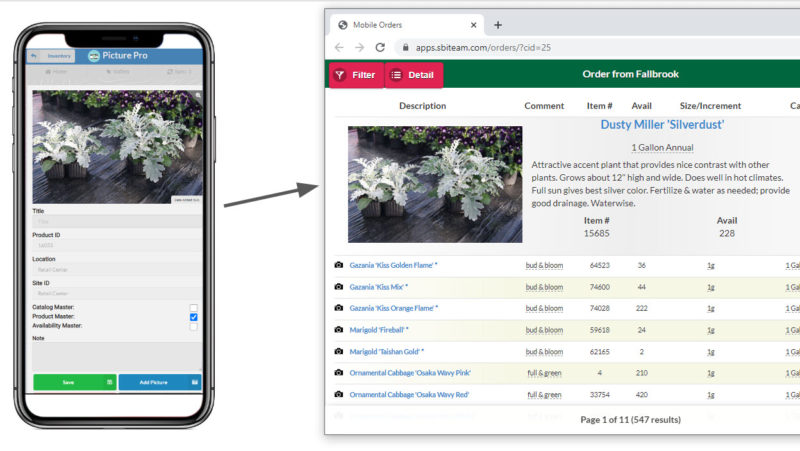

Working on mobile inventory control software since 2002, Aaron Allison, co-founder and CEO of SBI Software, has spent countless hours in the field seeing what works to enable growers to improve inventory visibility and increase sales without increasing labor and costs. Being able to share comments for sales or customer availability, grades or status for internal production teams, and crop photos has shown to be valuable.

“With staff turnover and lack of technical skills of the available work pool, we are now working to simplify down to just the functionality that the user is expected to utilize,” he says.

OPTIMIZE YOUR OPERATIONS

A helpful first step in implementing inventory control is to interview staff from all departments, including production, sales and shipping. Nuss says this is to find out what their frustrations, slowdowns and obstacles are in their daily tasks. “Inventory control then moves from an abstract concept to a set of identified benefit goals that keep all eyes on the prize,” she says.

Your product mix, space and sales channels will dictate the level of information detail you need to work with. “At the beginning of inventory control implementation, we have a lot of discussions to dissect the workflow and piece together the different levels of detail each department needs at each step,” says Nuss. Once this is understood, she says the right information processing steps and responsible parties are outlined to match. Documenting the steps in an inventory control standard operating procedure (SOP) document will keep everyone on the same page moving forward.

While software provides essential tools for inventory control, there are still “people problems.” Success comes when you exercise the discipline needed to not skip steps in your SOP, advises Nuss. “Assigning an inventory manager, who takes the lead and provides the accountability for the SOP, will help in leading you to success in your software usage.”

The immediate benefit of using software is being able to control the important aspects of your business. Production software provides the ability to automate production processes and schedule activities, so workers know where to be and what to do through a mobile application, Al-Abbasi says. Everything is recorded within the software and tracks the type of information growers need to be successful like fertilizing and watering schedules.

“Inventory software is the best way to accurately track inventory down to a specific location,” says Al-Abbasi. “The software enables growers to find and ship the product they need, knowing it will be where — and in the quantity — the system says it is. Barcode scanning tools keep the information up to date at all times. This has an immediate, positive effect on labor, with much less wasted effort. In addition to giving management more visibility into inventory, it is easy to set up automation for re-ordering supplies and raw materials when they reach predetermined levels.”

When production and ordering software are integrated with inventory and accounting tools, you no longer have double-entry of data as each component flows details into the other, says Al-Abbasi. This integration allows for visibility in cost accounting, so you can track material and labor costs at many levels.

CONSIDERING SOFTWARE SOLUTIONS

Ready to find your inventory software solution? It’s a great idea to look at the reporting tools beyond record keeping. “Your software should have the ability to provide deep dives into your spending and revenue, look at trends and generally help you determine how to optimize your business processes,” says Al-Abbasi. “Additional dashboards can put the most critical numbers on display for a quick glance at your business health in real time.”

Getting the data set up initially is an investment and takes time — and some trial and error — to refine processes and dial everything into a smooth flow. Nuss suggests “planning for a couple trips around the sun of continuous improvement, but once you get through it, you will agree it was worth it.”

Having applications that can be used to track moving inventory, transplanting, order picking, losses and incorporating production task assignments helps growers get the most from their inventory systems, says Allison. He sees a future where field teams will use a mobile device all day to access their work to-do list and connect with the full team all in one place.

Sidebar: Making Your System Work

Volumes can be written on inventory management for growers, says Sharon Nuss, CEO at Starcom Computer Corp., but here is her quick list of key points and benefits of an inventory control system to help guide you:

• Record accurate numbers and locations coming off the production line and put that data into the system as you plant.

• Integrated space planning can help direct crop placement and create a better fit for your production schedule.

• Record adjustments when containers move or get dumped instead of doing physical counts; the software will automatically reduce physical inventory when orders are pulled for shipping.

• Availability is all about monitoring crops to predict readiness.

• Information should be organized the way growers need it and provide flexibility for adjustments in crop readiness. Integrated mobile applications will increase the speed and accuracy of monitoring.

• When the database has the right inventory information, then software can help do the heavy lifting.

• If there are crop issues, affected orders are quickly identified and you can rapidly process order changes. Oversold issues are resolved before the pulling process starts, so last-minute substitutions are eliminated and preparing delivery paperwork is simplified.

• An inventory system has a detailed audit log of inventory adjustments and reason codes to identify waste. It can track chemical applications and analyze areas of improvement so you can refine your product mix and growing methods.

• Good inventory control supports more accurate cost analysis and overhead allocation.

For an enhanced reading experience, view this article in our digital edition by clicking here.

Video Library

Video Library