Cover Story — Improving Controlled Environment Food Growing Operations

AppHarvest began harvesting tomatoes out of its new 60-acre greenhouse operation in Morehead, Kentucky, in January. The company is expected to harvest about 40 million pounds of tomatoes annually from this facility. The greenhouses contain about 720,000 tomato plants, consisting of a mix of beefsteak and tomatoes-on-the-vine.

The company is also expanding its controlled environment food production in the state with a 15-acre facility in Berea, Kentucky, which will produce leafy greens, and a 60-acre facility outside Richmond, Kentucky, which is expected to grow tomatoes.

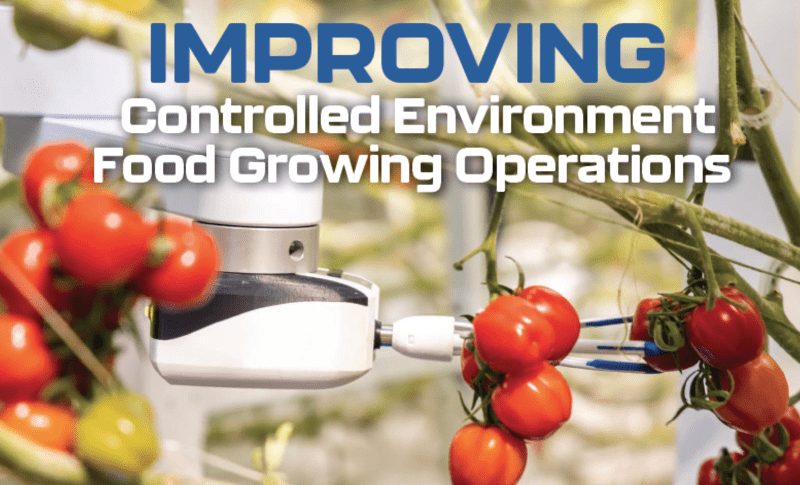

INCORPORATING AI, ROBOT HARVESTERS

In April, AppHarvest acquired Root AI, an artificial intelligence startup that designs intelligent robots for use in high-tech indoor farms. With this acquisition came Root AI’s robotic universal harvester, Virgo.

Root AI co-founder and CEO Josh Lessing has become chief technology officer at AppHarvest.

“I have a two-fold role with AppHarvest,” Lessing says. “My major role is to run TechCo, which will contain AppHarvest’s key technologies including proprietary FarmOps, robotic harvesting capability and AI/ machine learning for growing. TechCo also has the potential to develop a new revenue stream through licensing of CEA technology to global operators.”

He says TechCo is a subsidiary of AppHarvest that is focused on new technology for greenhouses. “We are very committed to CEA and see a bright future in expanding its capabilities. My team is focused predominantly on enterprise software, artificial intelligence and robotics to drive new kinds of efficiencies. The other part of my role is more broadly the technical operations manager for the broader farming company.”

Lessing says one of the biggest reasons to incorporate robots into controlled environment production operations is resilience.

“Harvesting is a very time-sensitive activity,” he says. “If a grower misses the moment of harvest, then all the effort and expense that has taken place to grow that crop is converted into a lost opportunity. Being able to incorporate a harvesting robot as a supplement to the people working in the greenhouse guarantees the harvest is completed in a timely manner.”

Utilizing robots can free up workers to focus on other aspects of crop care. “With crop care, there is so much more that can be done to ensure the plants grow at an optimal level,” Lessing says. “If people aren’t harvesting they can be pruning the plants. They’re making sure the right number of flowers is on a truss, which has a monumental impact on what is the final outcome of the harvest. The harvesting robot also frees up time for workers to lower the plant canopy. The gentler the canopy is lowered, the less heads that are broken on the vines as well as fewer fruits ending up on the floor due to rough handling. The more finessed plant care with the people that we have means better crop outcomes and more quality product.”

One of the biggest advantages of incorporating robots into its production facilities is the data the robots will collect as they harvest. The information collected by the robots will enable AppHarvest employees to evaluate crop health, precisely predict yield and optimize overall operations of the facility.

“When a fruit is harvested we have an opportunity to measure the outcome of an experiment,” Lessing says. “Every variable that is changed in lighting, temperature and fertigation is observed the moment we bring in the harvest. Having robots in the greenhouse allows us to collect a lot more data and allows us to close the loop and understand how to do better the next time so that we can keep driving up quality and yield.”

IMPROVING ROBOT TECHNOLOGY

AppHarvest is developing a robot strategy with the data being collected by the harvesting robots.

“We focus heavily on advancing our computer vision capabilities,” Lessing says. “We’ve built our own custom fully convolutional neural networks and run complex analyses at the edge of the robot. We’re doing a lot of computer vision models, including this is a tomato, this one is ripe or this is a leaf.”

After acquiring this information and the contents of the environment, they can then make judgment calls on how to best harvest a sequence of fruits. Those types of strategy decisions, Lessing says, are the core of modern dexterous robotic techniques.

“Worldwide there’s over $100 billion worth of hand harvesting of fruits, both CEA and field production. Writing the fundamental software that allows a robot to strategize the way humans move their hands in an environment to do sequential complex dexterous actions is a tremendous accomplishment.”

The Virgo harvesting robot has also been used on strawberries and cucumbers. It is the same robot with a slightly different picking hand. A large percentage of what happens with harvesting a berry crop is very similar to the issues that have to be managed with a tomato crop.

The Virgo harvesting robot has also been used on strawberries and cucumbers. It is the same robot with a slightly different picking hand. A large percentage of what happens with harvesting a berry crop is very similar to the issues that have to be managed with a tomato crop.

Much of harvesting with hydroponically grown leafy greens is already automated.

“I expect there is work that could be done with leafy greens in the pack house with quality inspection using robotics,” Lessing says. “It would be more of an industrial kind of manufacturing/packaging processing robotic line.

“One of the advantages with a fully robotic process from end-to-end is that systems can be built that are hyper-sanitizable, which with lettuce is a competitive advantage. Status quo is leafy greens coming from the field where there are so many ways in which crops can be exposed to pathogenic bacteria. Having a fully robotic work flow from the seeding to the growing to the packaging with sanitizable robots would allow delivery of an unparalleled safe crop.”

MAKING TECHNOLOGY AVAILABLE TO OTHER GROWERS

TechCo is AppHarvest’s product company with an international mandate to sell its technologies to other organizations worldwide.

“AppHarvest is focused on being a global leader in reducing the challenges to deliver operational excellence in greenhouses,” Lessing says. “We will lead the charge in selling these types of technologies into new markets, including the Arabian Peninsula, India and China. This technology includes robots and other forms of software and machine learning or more broadly artificial intelligence.”

Their goal is to develop multiple tiers of technology that can be added to other organizations. “Just because growers have a lower technology level in their greenhouse operations doesn’t mean that the technology AppHarvest is developing doesn’t have application,” he says. “There are parts of the world where growers can operate with a less sophisticated control environment infrastructure because they are the beneficiary of an ideal growing climate. These are places where growers don’t have to make big investments to grow their crops. At the same time, these growers would probably appreciate having AI that helps to steer their crops to get the most out of them. These technology products will be offered in different packages to meet the needs of different customers. This is part of AppHarvest’s focus on being an international company.”

For more information: Contact AppHarvest at info@appharvest.com or www.appharvest.com

Video Library

Video Library