Energy-Saving Climate Control for Cultivating Greenhouse Ornamentals

On both sides of the Atlantic, greenhouse growers are faced with the challenge of how to reduce energy costs in greenhouse cultivation. As a company that has developed horticulture lighting for more than 10 years, BLV Licht- und Vakuumtechnik is also frequently confronted with the issue of conserving energy.

Our experience with growers and research facilities all over the world has shown that precisely coordinating climate control and lighting holds a great potential for savings. We will therefore take a brief look at the German market, where a climate model developed at the Weihenstephan-Triesdorf University of Applied Sciences (HSWT) has been gaining ground in recent years.

Developing an Energy-Saving Model

Germany has more than 8,000 producers of ornamental plants with a total of more than 2,000 hectares of greenhouses. These companies generate a significant share of their revenues at the start of the garden and balcony planting season in the first weeks of spring and during the Christmas season with winter plants.

Winter and early spring are thus important cultivation periods in Germany. Many of the plants cultivated at this time, e.g. Euphorbia pulcherrima, need warmth and light, so greenhouses require heating and some lighting during these periods. The resulting energy consumption constitutes a considerable share of production costs. Therefore, an energy-saving model for cultivating ornamental plants was developed at Weihenstephan University (the Weihenstephan model), which has been adopted by many producers in Germany.

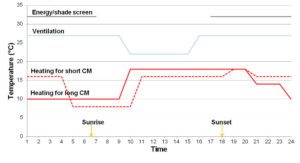

In contrast to conventional cultivation with constant day and night temperatures, the energy-saving model is based on dynamic temperature control. This involves using natural sunlight in the early afternoon to build up a heat reserve and closing the ventilation system early to retain this heat in the greenhouse. The energy reserve is used to provide heat during the early evening hours. Later, the heating level is reduced to a temperature that is still tolerated by the plants. The greatest savings are achieved by lowering the temperature in the greenhouse in the morning. Studies have shown that this cultivation model can lead to a reduction of 25 to 40 percent in energy costs with no major investment and no loss of plant quality.

A New Approach

Dynamic temperature control in greenhouses is a new and unfamiliar concept for the horticulture sector. It required a completely new approach to climate control parameters. Numerous studies have shown that with this model, the quality of the plants is comparable with that of those cultivated conventionally, (at least) under the light conditions in southern Germany.

In practice, the Weihenstephan model is implemented by setting the ventilation temperatures at 77 to 81° F three hours before sunset (warm evening). Optimally, three hours are enough to create a sufficient energy reserve in the greenhouse for the early evening hours. At dusk, the energy screens are closed. The heat loss can be further reduced by using shade screens. Additionally, under-table heating is recommended due to the reduced air volume (under the energy or shade screens), less energy is lost. Because of the higher temperatures, the effect of supplemental lighting is highest during this time (assimilation). In addition, the heat from the lamp is added to the heat reserve. As the heat from a sodium-vapor lamp increases leaf temperature by two to three degrees, the temperature control may need to be adjusted.

In the morning, the heating temperature, but not the ventilation temperature, is lowered (cool morning). This involves reducing the heating temperatures to a plant-specific lower limit at least one to two hours before sunrise. In this cultivation phase, the greenhouse can cool down naturally.

At dawn, the energy and shade screens are opened and the cold air from the upper levels of the greenhouse is mixed with the warm air from the plant area.

Minimum temperature limits are set to protect the plants, but they are rarely reached. The lower temperatures in the morning have the additional positive effect of reducing elongation growth (internode elongation). Concerns that this effect could be eliminated by lighting with discharge lamps have not been confirmed in studies to date. However, the effect of supplemental lighting tends to be less in the morning than in the afternoon due to the lower temperatures. Because the heat radiation of HPS lighting increases the leaf temperature, some growers use their lighting to prevent water condensation during this period of time.

Especially on sunny days, natural sunlight warms the air in the greenhouse. The heating is switched on only if the greenhouse is insufficiently heated after four to five hours. Figure 2 shows the schematic representation of the control settings. From an energy conservation perspective, it is not reasonable to heat the greenhouse during the morning hours, only to later give off the costly energy through the ventilation.

However, the model must be adapted to the specific plants and regional conditions. In some cases, for example, it may be useful to provide higher heating temperatures in the evening hours and start the cool morning just shortly after midnight.

Growers with high-tech equipment have the advantage of being able to set the heating and ventilation parameters individually. Energy or shade screens are additional options for reducing heating requirements at night. However, practical experience has shown that regular monitoring and maintenance of the sensors is necessary, especially if temperatures in the greenhouse are set at the limits. Dry cultivation supports the overall result. If watering is scheduled before noon, humidity does not increase unnecessarily in the evening. Regional weather conditions such as the hours of sunlight also affect the cultivation success.

Proven Success

The model was developed at HSWT in 2008 and has been tested continuously. The Institute for Horticulture thus has many years of experience. Today, around 50 percent of growers in Bavaria (largest federal state of Germany with an area of 70.550 square kilometers) use the approach. The results throughout the past eight years have shown that by increasing the greenhouse temperature in the late afternoon (warm evening) and the systematic use of energy screens, heating does not need to be turned on until significantly later.

At the same time, less energy is used for heating when the temperature is lowered in the morning, while achieving a nearly identical daily mean temperature (DMT). As tests have shown, between 25 and 80 percent of the energy normally required for heating was saved (Figure 1). For a greenhouse of 1 hectare, this results in energy savings of at least 250 MWh.

Over the years, the model has been tested on nearly all relevant ornamental plants. The results show that these crops can be grown with no loss of quality. Figure 1 presents the energy savings achieved in a few economically significant crops.

As the model uses natural sunlight as a heat source, energy savings increase with the number of hours of sunlight. Interested growers should therefore first determine the hours of sunlight at their location. For comparison, in southern Germany, where the model is used primarily at this time, there are approximately 120 hours of sunshine in October and March and 50 hours in December and January. To compensate for the lack of sunlight, we recommend the use of high-pressure sodium lamps. With the combination of high photosynthetically active radiation and intensive thermal radiation, sodium-vapor lamps support growth and also build up the necessary heat reserves.

For any questions on energy-saving climate control or supplemental lighting, please feel free to contact the BLV Horticulture team.

Video Library

Video Library