Grower Success Stories: North Carolina Farms

Mitchell Donahue may have started North Carolina Farms as a hobby business selling ferns out of a homemade greenhouse, but now it’s blossomed into an unstoppable force selling wholesale plant starters to greenhouses and garden centers. Today, Donahue’s two eldest sons, Mick and Brad Donahue, share the responsibility of running the family enterprise together — one handling the business side while the other oversees planting production.

While Brad grew up with North Carolina Farms, he wasn’t set on his career path despite double majoring in agriculture education and horticulture at North Carolina State University. He considered the prospect of teaching after graduation, but his time spent driving back and forth from college to the family farm to work in the greenhouse solidified his decision.

“I was going to NC State and then coming home every weekend and working at the greenhouse. I enjoyed it that much that I drove [up to] three hours,” Brad said. “By my junior year, I realized, yeah, that’s what I wanted to do.”

Mick and Brad work alongside their sister-turned-office manager, Karen Bland, to manage a year-round team of roughly 30 employees, and an additional 40 to 50 seasonal staff members. However, the entire Donahue family pitches in when they can — from their “semi-retired” parents, to the siblings and their spouses — by creating the annual catalogue, hosting a marketing course for customers or maintaining payroll and bookkeeping. Everybody has found the thing they are great at, establishing a strong team to carry the load when needed.

CELEBRATING 50 YEARS

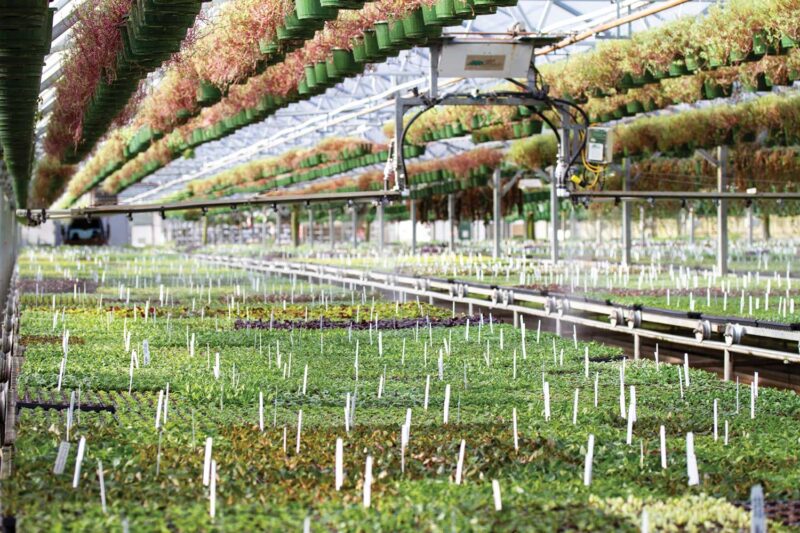

As a teenager in 1973, Mitchell became fascinated with the idea of producing several plants from a single cutting. What began as a bare root backyard dream grew into today’s family-run operation, with 3.5 acres for propagation and stock greenhouses used to produce 10 million starter plants in 2024.

Today, as North Carolina Farms celebrates its 50th year with 13 grandchildren spending their time at the greenhouses, it’s easy to assume North Carolina Farms may continue for another 50 years.

HANDS-ON HEEDFULNESS

In a world that leans toward outsourcing customer service inquiries, North Carolina Farms continues to offer a hands-on approach and stays rooted to the company’s philosophy.

“Our tagline is: We grow your business,” Brad said. “Our goal is to give the customer the support they need. Right before (this interview), I was giving some advice to a guy who’s starting a lavender farm. We’ll ship him some lavender and coach him through it.

“Everyone has the same value to us, no matter how many plants they are getting. We’re just looking to help as much as we can. Myself or my head growers are available to talk on the phone with our customers to work through any issues.”

TRIALS AND TECHNOBABBLE

TRIALS AND TECHNOBABBLE

Donahue said technology, in all its forms, can be the key to handling industry challenges.

“Efficiency is technology,” Brad said. “It’s knowing which automation and technology we should go after, which ones are too new that need developing, and which ones we should implement.”

He believes that technology is something to embrace. “My advice to any grower is don’t be afraid of technology. (Start) small and then grow it as you get a handle on it,” Brad said.

North Carolina Farms has an RFID system that had been years in the making through implementing and trialing before good chips were available for greenhouse production.

“We saw the potential. (Now) when we plant a tray, it gets an RFID sticker on it and we know it’s in inventory, and we can track it to within 20 feet,” he said.

Once the tray is in inventory, it’s placed in the dual temperature range propagation house. Cuttings start on the warm side, and once root development starts they are pushed to the cooler side. Plant trays travel to the coolest end of the greenhouse before shipment.

“Since the [plants are] constantly moving, we need to know where they are and when it’s time to ship,” Brad said. “With the RFID stickers, it helps us know where the oldest tray in the house is, which makes us more efficient and prevents waste.”

GREEN PRACTICES

When it comes to sustainability, North Carolina Farms is focused on what it can control.

“Propagators generate a lot of waste,” Brad said. “The propagation trays are sent out for recycling. We try to not have overspray (because) waste of water is also wasted fertilizer.”

The RFID system also ties into the company’s sustainability efforts.

“The good thing about efficiency is it typically gets rid of waste on all sides — waste of time, waste of product and more. If you grow a plant well and get it ready to go out the door in less time, then you use less water and fertilizer,” Brad said.

North Carolina Farms also takes an eco-friendly approach to mitigate chemical use.

“We use a lot of beneficial insects and biological controls to cut back on pesticides,” Brad said. “There’s a learning curve with beneficial insects but once you figure them out, you can do as good or better of a job controlling the pests.”

LOOKING AHEAD

LOOKING AHEAD

North Carolina Farms keeps customers in mind when doing market research.

“We’ll go to nine different trade shows next year to see our customers and get feedback on what worked well, what didn’t, and what they’d like to see added next year,” Brad said.

North Carolina Farms has recently started to explore seedlings and other new plants. Much like the approach to technology, it’s important to start small and expand once prepared.

“Initially I wanted to start with a tray or two of seedlings and test it out,” Brad said. “We’ve become pretty comfortable with our production schedules on seedlings, so we’re adding [them].”

With a hands-on commitment to customers, nothing is done without first establishing a strong knowledge base to help mitigate any problems growing new products.

“We’re looking to really extend our season by focusing on crops we currently have or adding new crops,” Brad said. “We recently added poinsettias. We bought 3,000 cuttings, rooted them, grew them and actually finished them.”

As a company that doesn’t sell finished product, North Carolina Farms then gifted the finished plants to local nursing homes.

“During our testing we took lots of pictures and documented everything really well, so that as we’re coaching our customers on how to grow and finish a poinsettia, we have actually done it,” Brad said. “We like to be hands-on, because we like talking to our customers.”

Video Library

Video Library