Has Your Greenhouse Gone Virtual?

What image first popped into your mind? Virtual Grower? Or perhaps, visions of creating or updating your company's website, Facebook page, Pinterest board, Instagram and Twitter accounts, and/or other social media platforms?

Virtual Grower is a free decision-support software program available from USDA-ARS that allows users to build a virtual greenhouse (e.g., their existing greenhouse or the greenhouse of their dreams). This software program was initially designed to help greenhouse growers estimate heating costs and conduct simple simulations to figure out where heat savings could be achieved. Features have been slowly added, and now Virtual Grower can help assist with a suite of decision-making scenarios. It can, in a sense, be a safety net by allowing users to experiment with "what if" scenarios in a risk-free setting.

Here are just a few of the scenarios and simulations that Virtual Grower can assist with:

• compare energy costs of different greenhouse designs and materials before committing to a new greenhouse structure,

• compare energy costs across multiple locations

• compare energy costs for various fuel sources based on current and predicted pricing

• estimate cost savings that may be achieved by upgrading or retrofitting an existing structure with energy-efficient components

• make real-time predictions of energy use

• see the impact of supplemental lighting on plant growth and development

• assist in crop scheduling by calculating a start date for a crop based on a target finish date

• estimate total energy costs during crop production at different temperature set points.

Virtual Grower, initially released in 2005, was the brainchild of Dr. Jonathan Frantz (formerly with the USDA-ARS in Toledo, Ohio). Since then, we have expanded and enhanced the program so that it now is compatible with Mac and PC computers, is available in three languages (English, Spanish and French), and includes data for more than 40 crops. Since its initial release, more than 20,000 copies have been downloaded by users in 84 countries! At present, Virtual Grower 3.0 is our most recent version and available for download from our website (www.virtualgrower.net).

Case study #1: Estimating cost savings by implementing energy-efficient design elements

Virtual Grower has wide application for greenhouse managers, growers and students. While it will not supplant an actual energy audit, it can provide estimates of heating costs and the cost savings that may be attained by making small as well as large changes to a greenhouse. For example, consider a greenhouse with six spans (25×100 feet each; 15,000 square feet), located in three different sites (Toledo, Ohio; Charlotte, North Carolina; and Orlando, Florida). It is covered with a double poly roof and a single layer of poly on the side walls. It does not seal very well and has several large and small holes, due to rips in the plastic, gaps under doorways, or

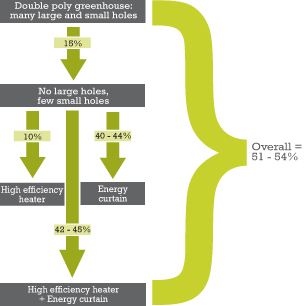

roll-up walls that do not sit snugly along the bottom or along the corners. Estimated heating costs would be approximately $8.07, $3.62 and $0.72 per square foot per year in Toledo, Charlotte and Orlando, respectively (Table 1). Patching the holes and sealing the side walls so there are no longer any large holes and only a few small holes could decrease heating costs by 15 percent. That's a big return on a small investment of time, labor, and supplies! Further decreases in heating costs could be achieved by replacing existing unit heaters with high efficiency heaters, installing an energy curtain, or both (Figure 1). Implementing all of these could reduce heating costs by $4.10 (Toledo), $1.86 (Charlotte) or $0.38 (Orlando) per square foot per year, which adds up to a 51 to 54 percent savings in heating costs!

Likewise, picture a glass roof greenhouse with bi-layer polycarbonate siding. By eliminating holes/gaps and installing knee walls, high efficiency heaters, and an energy curtain, heating costs could be reduced from $5.37 to $2.30/ square feet/year in Toledo or from $2.41 to $1.03/square feet/year in Charlotte, a savings of 57 to 60 percent (Table 1)!

Of course, the potential reduction in heating costs will need to be weighed against the cost of installation for any of these retrofits or upgrades, but the payoff time could range from less than a year to a couple of years (or even quicker if fuel costs increase). With Virtual Grower as your 'crystal ball', you are able to virtually create as many greenhouse designs and scenarios as you would like, compare them, and run the energy cost calculations before deciding whether to invest in an upgrade/retrofit to an existing structure or building a new greenhouse.

Case study #2: When to transplant for a target finish date

Suppose you have a target finish date for a crop and are trying to decide when to transplant and what the most cost-effective greenhouse temperature would be. Transplant date will depend on temperature, which influences crop developmental rate. Growing at cooler temperatures is more cost effective on a daily basis but will lengthen crop production time, which may negate any per day cost savings because of the longer production time. Of course, growers will also need to consider other factors, such as a reduction in the number of crop turns per season as crop time increases and fixed costs per square foot per week, but let's set those aside for now. For a finish date of May 1, pentas grown at 75/65¡ F day/night in a glass roof greenhouse (as described in case study #1) will need to be transplanted on or around March 16 for both Toledo and Charlotte. The estimated heating costs during production at 75/65¡ F are $0.18/square feet in Charlotte and $0.35/square feet in Toledo (Table 2). Growing them at a reduced temperature of 65/55¡ F will increase the length of production to 71 days (i.e., transplant on Feb. 19). Factoring in the increased length of production, estimated total heating costs decrease to $0.17/square feet in Charlotte, but increase to $0.43/square feet in Toledo. A similar example is shown in Table 2 for Wave petunia. In addition to calculating transplant date, we have incorporated a metric of plant quality into Virtual Grower. For example, as temperature decreases from 75/65¡ F to 65/55¡ F, pentas plant quality (indicated as plant weight) decreases. Therefore, even though the heating cost per square foot will be slightly lower at the Charlotte greenhouse at lower growing

temperatures, the reduction in plant size may not be desired. On the other hand, petunia plant weight will increase as temperature decreases, indicating that cooler growing temperatures enhance plant growth. However, heating costs will be slightly increased. The balance between heating costs and plant quality will both need to be considered when making a final determination as to what temperatures during production will be best for your growing operation.

Looking Ahead

After a ten month hiatus in technical support and product development due to staff turnover,

Virtual Grower is once again supported by a research scientist and IT specialist. In May we welcomed Adam Hall to our team as our new

software developer. We are excited to announce that two updates to Virtual Grower will be released in the coming year. Virtual Grower 3.1 will be an update to the current version and will include design updates and improvements (Figure 2). Virtual Grower 4.0 will include program enhancement and expansion. Here is a sneak peek at some of the improvements you can look forward to:

Virtual Grower 3.1:

• Improved graphics •More than 100 new locations added, increasing the total to 930 locations • Additional plant species added •

Virtual Grower 4.0:

•All the improvements from Virtual Grower 3.1, plus

•Built-in language option: English, Spanish and French will be available in the same download. Language will be selectable in the options tab, just like units. This will allow users to create greenhouses and run simulations in one language, then instantaneously switch to another language, if needed, in order to share it with a colleague or supervisor. Additional languages may be added in the future.

•Expansion of the lighting options tab to include LEDs.

•Expansion of plant quality metrics.

• Addition of plant growth models.

We Want to Hear from You

Our goal is for Virtual Grower to be as useful and user-friendly as possible. Many of the improvements in earlier versions came from feedback from users. We want to hear from you — please, tell us what you like or don't like about it, features that you think are missing, or suggestions for what should be added. You can contact us at VirtualGrower@ars.usda.gov with comments, questions and feedback.

Has Your Greenhouse Gone Virtual?

Video Library

Video Library