Light Fixtures and Their Photon Fluxes

Until recently, there were only three major types of lighting fixtures used for the production of plants in controlled environments: incandescent bulbs for photoperiodic lighting, high-pressure sodium fixtures for supplemental lighting in greenhouses, and fluorescent tubes for plant production indoors.

The light output of new fixtures was relatively constant for a particular type and wattage. Tremendous advances in the technology of light-emitting diodes (LEDs), as well as burgeoning cannabis and indoor farming industries, have increased the demand for plant lighting. This has led to a myriad of LED fixtures that come in all shapes, sizes and outputs — more technically, photon fluxes and spectra. This article explains the photon flux emitted by a light fixture and why it is important.

Photons are particles of light with different wavelengths. Flux is the action of flowing. Therefore, photon flux is the number of photons that flow per

unit of time. In plant lighting applications, we use the unit micromoles (μmol) for instantaneous photon measurements (per second, s) and moles (mol) for daily photon accumulations (per day, d). With lighting fixtures, we usually quantify photon flux on an instantaneous basis and use the unit μmol/s or μmol·s–1. Note that there is no mention of area, so photon flux does not describe density.

In most cases, we are specifically interested in the number of photons with wavelengths between 400 and 700 nm, since these photons have the energy that power photosynthetic reactions. This traditionally defined waveband is called photosynthetically active radiation (PAR). Therefore, the photosynthetic photon flux (PPF) of a lighting fixture refers to the flow of photosynthetically active photons. The output of UV and far-red light, which are outside of PAR, are also relevant because those photons cause biological responses. In particular, research has shown that far-red light can directly and indirectly increase plant growth. However, the PPF only includes photons in the PAR waveband.

The PPF of a lighting fixture is measured by an integrating sphere, which is a hollow sphere whose inside is covered by a white coating that is highly reflective and diffusive. A fixture is placed inside the sphere under environmentally controlled conditions, and a detector measures the light output. Therefore, the PPF is not something that growers or most academics can measure.

The PPF of a fixture enables one to compare outputs of various conventional and LED fixtures. When the power draw to emit the PPF is also measured, one can calculate the photosynthetic photon efficacy of a fixture, which describes the number of photosynthetically active photons emitted per unit of energy.

These values, in the unit of μmo·J–1, quantify the relative efficiencies of different lighting products.

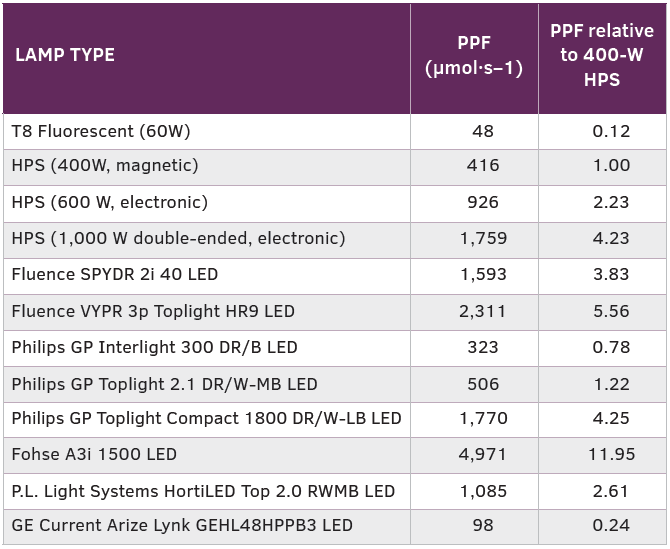

Table 1 provides examples of the PPF emitted by various lighting fixture types and products. The values range tremendously for conventional fixtures as well as LEDs. The fixtures have a range of applications; for example: T8 fluorescent and GE Current Arize Lynk are for indoor plant lighting; Philips GP Interlight is for inter-canopy lighting of high-wire crops such as tomato; and high-pressure sodium (HPS) and several of the other LEDs are for supplemental, overhead greenhouse lighting. While the applications of these fixtures may differ, their PPFs can be compared to a particular fixture, such as a 400-W HPS. For example, the P.L. Light Systems HortiLED emits about 2.6 times more photosynthetic light than a 400-W HPS.

Most horticultural lighting companies report the PPF for each of their lighting products. Growers can use that information to get ballpark estimates for how many LED fixtures would be needed to replace existing HPS fixtures, assuming they have been well maintained. In many cases though, the output of HPS fixtures is lower than that in the tables, since their output decreases with bulb life, as reflectors get dirty, etc. In addition, LED lighting can be more targeted than HPS fixtures, meaning that less light is lost to non-target areas such as walls and walkways.

Finally, fixtures that emit a large PPF are not necessarily better than those that emit a lower PPF. Generally, the distance between a lamp and the plants must increase as the PPF increases to achieve reasonably good lighting uniformity. Growers with short greenhouses will usually have more uniform lighting with more low-PPF fixtures than with fewer high-PPF fixtures. Growers are encouraged to work with lighting companies and their distributors to obtain lighting plans specific to their operation.

Video Library

Video Library