Perennials: Size Matters

We’ve all heard the expression “size matters,” but many growers overlook the value or savings larger starting materials provide when planning their perennial programs. So many of us are fixated at the upfront costs of starting materials that we often lose sight of the true costs of producing a perennial crop. As you’ll soon learn, when it comes to profitability, size does matter.

LAYING THE FOUNDATION

To demonstrate how larger starting materials, albeit more costly upfront, can increase profitability, it’s important to consider a couple of key factors to determine the actual costs of production. The first factor is the time factor or the number of weeks a crop will be in production. The next factor is the overhead costs or the costs associated with the space required for producing them.

Overhead is the cost associated with being in business. Although I can’t cover how overhead is calculated in great detail here, I’d like to establish a general idea of what overhead costs are for many perennial producers. In order to do so, it’s important to explain the concept of “square foot weeks” as the cost associated with each square foot in production per week.

Square foot weeks are essentially derived by taking all a business’s overhead costs and dividing them by the total square feet of production space and then dividing this number by the number of weeks that space is being utilized for production. The value for square foot weeks varies from business to business and usually falls somewhere between $0.20 per square foot week for less sophisticated facilities and $0.40 per square foot week for state of the art facilities.

To keep things simple and ease of demonstration, I’ll use an overhead cost of $0.30 per square foot per week in the following examples. For simplicity, I’d also like to assume that the crop spacing is 1.5 containers per square foot in these examples. Now let’s dive in to see how the costs of inputs and time affects profitability.

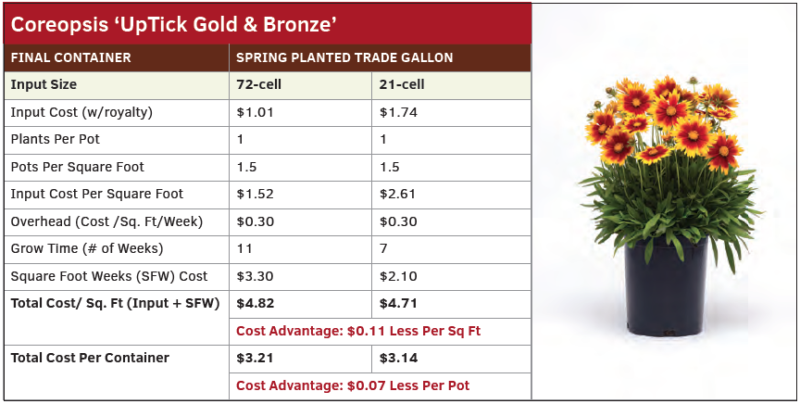

COREOPSIS ‘UPTICK GOLD & BRONZE’

For this example, let’s compare the costs of producing a one gallon crop of coreopsis UpTick when using 72-cell or 21-cell liners and planting them in the spring.

As you can see, the 21-cell liner costs $0.73 more per plug than the smaller 72-cell size. However, the larger sized starting materials can be grown in grown and sold four weeks faster. Therefore, the total overhead or square foot weeks (SFW) cost to produce this coreopsis using the larger 21-cell liners is $1.20 less than the cost to produce them using 72-cell liners.

The end result is the larger sized starting materials costs $0.07 less per container or $0.11 per square foot to produce than when growing them using the smaller sized input which requires more production time.

Now this might not seem like much savings, but consider the following. An $0.11 per square foot savings is equivalent to saving $110.00 per 1,000 square feet of production space. Still not impressed, if you’re a large grower the $0.11 savings per square foot amounts to an impressive cost savings of $1,110.00 per 10,000 square feet or $4,791.60 per acre. These savings go right to the bottom line — your profits.

Wait, there’s more. If you’re like most growers, I’m guessing you’re interested in double cropping your production space. I won’t show the math here, but how valuable would it be to reduce the crop time and be able to get the second use of the production four weeks earlier? For some growers, this would likely be just as — but probably more — valuable than the cost savings obtained from the first crop.

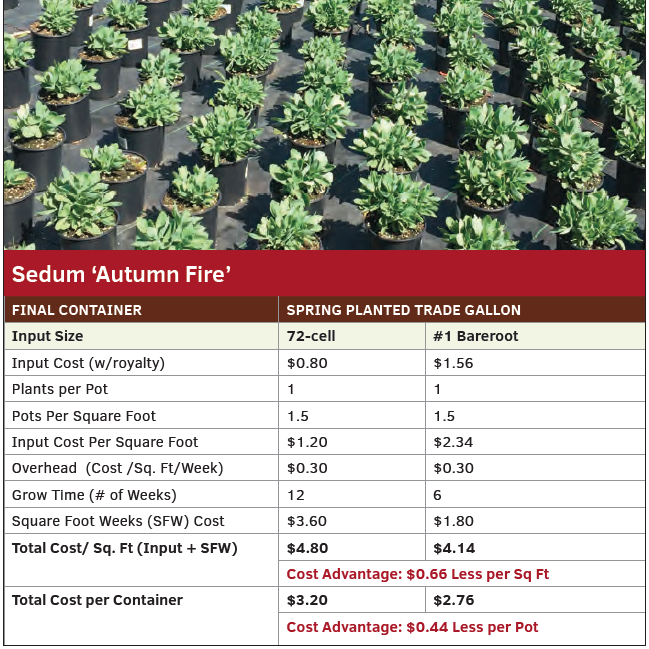

SEDUM ‘AUTUMN FIRE’

Using bareroot starting materials is another great example of how to obtain a cost savings for many perennials. Let’s take a look at the production costs with sedum ‘Autumn Fire’ using bareroot and 72-cell liners.

I hope you’ve noticed that the bareroot starting materials costs nearly twice as much as the 72-cell liners. I understand that it might seem like a stretch for me to ask you to consider doubling the costs of your inputs. However, I assure you that you’ll likely consider this a viable option once you look at the numbers.

Sedum from bareroot can be finished (non-flowering) in half the time of the smaller inputs. The reduced production time is where the cost savings comes from. In this example, the grower would realize a cost savings of $0.44 per container or $0.66 per square foot when opting to use the larger bareroot starting materials.

How much does this add up to? A savings of $0.44 per container adds up to $44.00 per 100 pots or $440.00 savings for every 1,000 pots produced. If you prefer to look at the reduced production costs in terms of square footage; the $0.66 per square foot savings amounts to $660.00 per 1,000 square feet or $6,600.00 per 10,000 square feet or $28,749.60 per acre. As you can see this adds up to some pretty serious cash.

In addition to the cost savings, I’d like to add that the plant quality (fullness) using spring planted bareroot sedum will be considerably higher than what can be obtained when 72-cell liners. More fullness, no pinching, faster crop times and

a significant cost savings, now doubling the cost of the input doesn’t seem so bad does it?

HEMEROCALLIS ‘STELLA DE ORO’

In this last example, I’d like to emphasize another important factor growers should take into consideration when purchasing perennial starting materials. To reduce the production times, improve plant appearance/quality and to maximize profitability, utilize starting materials that are appropriate for the size containers they are going into.

Both of these images to the left show hemerocallis ‘Stella de Oro’ in the same-sized trade 1-gallon containers. The top image is planted using #2 grade bareroot plants. The bottom image was planted with #1 grade bareroot starting materials. I think it’s obvious, but which crop is going to finish faster and have a better appearance for the consumer? That means the other crop is going to be on the ground significantly longer, cost more to produce and will likely not be as full. Just looking at the image on the left, I wonder how many additional weeks it would take to produce a high-quality plant? And, with the increased production time, is using smaller, less expensive starting materials even profitable to produce?

SIZE DOES MATTER

I think you can see from these examples that size does matter. I’m not asking you to change your entire program by shifting everything to larger inputs. In many cases, it’s not necessary to do so. At the very least, I hope I inspired you to take a look at some of your perennials and given you a few ideas on how you can possibly increase plant quality, decrease production times and increase the profitability.

There are several factors that will influence the price of starting materials and overhead costs; therefore, your input and production costs and potential savings will vary from the examples I’ve shown here. I encourage each growing operation to conduct their own calculations using their actual costs, crop spacings and grow times. Crunch the numbers and choose the starting materials that make the most “cents.”

Video Library

Video Library