Precision Control of Supplemental Lighting

Supplemental lighting is important in facilitating winter-time greenhouse crop production in many areas of the United States. LED fixtures are becoming increasingly popular due to their higher efficacy and longer lifespan, as compared to HPS fixtures. However, one other advantage of LED fixtures, the ability to precisely dim them, is typically overlooked.

Most, though not all, LED fixtures are dimmable, providing exciting new opportunities to precisely control how much supplement light is provided. However, in most cases, LED fixtures are largely treated like HPS fixtures, with on/off control based on a light threshold or using a timer. Such supplemental lighting strategies typically do not provide good control over the daily light integral (DLI), resulting in either excess lighting costs or suboptimal light levels for the crop. Given the importance of light for crop growth, good control over how much supplemental light is provided will affect the profit margin of the greenhouse business.

TAKING ADVANTAGE OF DIMMABILITY

The dimmability of LED fixtures provides unique opportunities for precision control of supplemental lighting that cannot be achieved with HPS fixtures. The light output from LED fixtures can be adjusted continuously to maintain a consistent light level at the crop canopy, without a negative effect on the life expectancy or efficacy of the fixtures. Maintaining a consistent light level at the canopy throughout the growing season helps to achieve consistent crop growth and increase the predictability of crop production.

HOW DOES IT WORK?

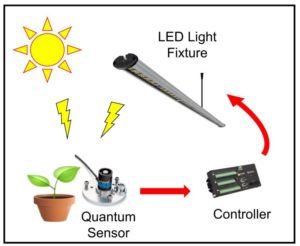

We developed an Adaptive Lighting Control (ALC) system that measures the amount of light at the canopy level and adjusts the amount of supplemental light that is provided in real-time to ensure that the desired DLI is reached by the end of the photoperiod (Figure 1).

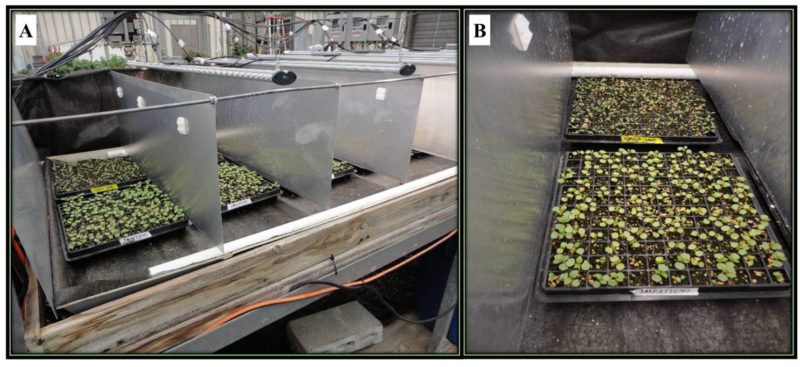

We tested the performance of the ALC system in a greenhouse to compare the daily light integral (DLI) we achieve with our ALC system to a timer-controlled system. Impatiens ‘Accent Premium Violet F1’ was grown using three different lighting treatments: no supplemental light, 100 μmol·m-2·s-1 for 14 hours per day (timer-controlled), and ALC with a DLI target of 8 mol·m-2·d-1 within a 14-hour photoperiod (Figure 2, page 26).

WHAT HAVE WE FOUND?

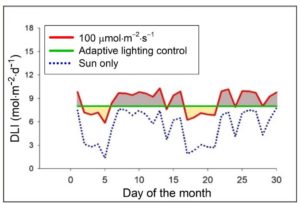

During the 30-day study, the plants received an average DLI of 5.4 mol·m-2·d-1 from sunlight and 8.6 mol·m-2·d-1 with the timer-controlled lighting. The lowest DLI received from sunlight was 1.4 mol·m-2·d-1 and the highest was 7.8 mol·m-2·d-1 within the 30-day period.

On overcast days, timer control of lighting did not provide enough light to achieve the target DLI, while it provided excess light on sunny days (Figure 3). On the day we had 1.4 mol·m-2·d-1 of sunlight, plants in the timer-controlled treatment received a DLI of only 5.9 mol·m-2·d-1 at the plant canopy, 2.1 mol·m-2·d-1 lower than the target DLI. On the other hand, the day with the highest sunlight, plants in the timer-controlled treatment received a DLI of 9.8 mol·m-2·d-1, 1.8 mol·m-2·d-1 extra light than the target DLI. In comparison, the ALC system provided the exact amount of supplemental light to reach the target DLI, regardless of weather conditions (Figure 3); the DLI was exactly 8 mol·m-2·d-1 every day. The ALC system ensures the crop gets adequate light on overcast days, while ensuring that no excess light is provided on sunny days.

At the end of the study, impatiens seedlings grown with ALC system had well-developed root systems and shoots (Figure 4A and 4B). When comparing the shoot and root dry weights of those seedlings with the seedlings grown under timer-controlled treatment, we did not observe a difference in growth. However, due to the consistency of the light output that can be provided with the ALC system, it is possible to precisely time seedling growth regardless of the weather condition, which fluctuates in timer-controlled systems.

When comparing the seedlings grown under the sunlight only treatment with the treatments with supplemental light, we observed poor shoot and root growth. We also calculated the plant compactness of seedlings, a measure of quality, by dividing shoot dry weight by height of the plants. Seedlings grown under the ALC treatment and timer-controlled treatment had a similar level of plant compactness (1.2 and 1.5 g/m respectively), while it was much lower in seedlings grown with sunlight only (0.6 g/m). Thus, supplemental lighting can increase seedling growth and quality, while ALC can ensure that the crop gets the desired amount of light.

We transplanted the seedlings into 4-inch pots and kept them in the greenhouse without supplemental lighting for several weeks to observe the growth (Figure 4C). We observed a uniform vegetative growth and flowering from those impatiens plants (Figure 4D).

TAKE-HOME MESSAGE

Adaptive lighting control can effectively control the light output of LED fixtures to provide the same DLI to the crop, regardless of weather conditions. This can increase both consistency and the predictability of seedling production, allowing growers to meet delivery dates and production schedules.

Video Library

Video Library