A team approach

The Van Wingerden name is synonymous with greenhouse growing, as Aart Van Wingerden is considered a pioneer in the agricultural medium, opening up his first commercial greenhouses in 1972 in North Carolina.

So, it’s no surprise that his grandson, Ed Van Hoven, founded his own greenhouse business in 1998. After all, he grew up around the industry, learning lessons from his grandfather and his father, Jerry Van Hoven, who also spent the majority of his life in the industry.

In fact, Van Hoven jokes that he probably took his first steps in a greenhouse because he was just always around them growing up, both at his grandfather’s operation and his father’s facility, who started his own venture in Virginia.

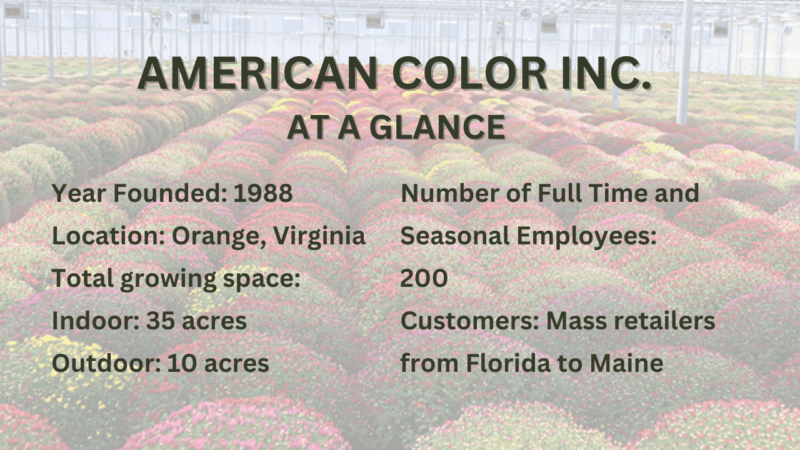

American Color, Inc., began in Orange, Virginia, with Van Hoven relying on a strong work ethic, his faith in God, and the unwavering support of his family — wife Gwen and children Brandon and Brooke.

“We started with an acre of greenhouse on the hayfield, and the idea at the time was to grow for independent garden centers,” Van Hoven said. “Today, it’s 35 acres.”

Both his kids are involved in the business today, carrying on the legacy, ensuring American Color will continue growing gorgeous flowers for generations to come.

EVOLVING THOUGH THE YEARS

While the early days saw Van Hoven handle most everything himself, today the company employs approximately 200 people, numbers that have stayed steady over the last decade.

American Color operates 35 acres of greenhouse and does around $45 million of business each year, delivering product to mass retailers from Florida to Maine.

“Our target customers are wholesale clubs and groceries up and down the East Coast,” Van Hoven said. “We’ll also go over to Central Tennessee.”

During spring, American Color offers a wide selection of flowers from Angelonia to Zinnia. In the fall, some of the most colorful flowers are grown, including asters, garden mums and Montauk daisies. For winter, poinsettias are most popular.

Of course, there have been lots of changes in the industry throughout the years.

“Greenhouses are ever-evolving and the greenhouses of three years ago looks much different than what you see today,” Van Hoven said.

What American Color strives to do better than anyone else is meet customers’ demands, even if an unexpected big order comes in.

Van Hoven’s business philosophy comes down to treating everyone fairly and providing the best quality for the price.

“You just need to be fair,” Van Hoven said. “In today’s environment, you go to a gas station where you’re paying $4 and two years ago you were paying $2. So, if we’re going to have to go from $2 to $4 on a plant, we want to be fair about it. We don’t want to be that company that’s just looking for an extra dollar without giving you anything in return.”

When deciding on new products, American Color’s sales department has a marketing arm that’s always looking for what they are not growing, what customers are asking for and listening to what breeders and brokers are talking about.

“We look to see if it fits the bill for our customer pool, and it’s an ongoing effort,” Van Hoven said. “You lean a lot on what your sales department is hearing.”

One area where change has come is in the advancements of tech and automation.

“We’re fairly highly automated,” Van Hoven said. “We believe in making things as automated as possible. We want to be hospital clean all the time, which makes it easier to automate things because not everything is in the way. We want things to run at 100%, 100% of the time.”

Still, Van Hoven believes that you have to weigh the cost of the automation versus the job at hand.

“There has to be a rate of return on automation,” he said. “We make sure that that return rate is there by the time the piece of equipment is expired.”

For example, adding shade systems and curtain systems made sense financially because it had a legit payoff.

“We’ve been fortunate that since our inception 25 years ago, as you’re building on so much, as you automate, it doesn’t cut into the current labor pool,” Van Hoven said.

Since American Color’s beginnings there has been a focus on being highly sustainable. “All of our water water is 100% recaptured and our chemicals are in a closed environment and has remained sustainable,” Van Hoven said.

Over the last five years the company has switched to using PTS (pine tree substrates), the less biodegradable materials in a person’s garden with a wood chip that’s highly biodegradable and also utilizes as much recyclable plastic as it possibly can on containers.

A TOP TEAM

Across the greenhouse spectrum, most companies strive to grow the best product and give the best price by getting it in front of the customer at the right time, so there’s not as much things to distinguish one greenhouse grower from the next as it was a decade ago.

The biggest key to success through the years, Van Hoven noted, is the team he has surrounding him, starting with son Brandon who runs most of the day- to-day operations, his daughter, Brooke and son- in-law, Curtis.

“Our uniqueness comes from the strong string of people we have,” Van Hoven said. “Our heads of departments are a well-oiled machine. Everyone knows what they’re doing every day without needing to discuss it. The second generation in a lot of places start to fall apart; not always but it’s a smaller pool when the next generation does things better.”

The strength of American Color comes from its team, with some strong young players running the show and some older players inserting wisdom and experience to make everything run like clockwork.

GIVING BACK

Another big part of American Color’s philosophy is giving back to the community and the world as a whole. “Naturally, we’re in business to make money and progress, but we’re also here to give back and help those less fortunate,” Van Hoven said. “At American Color, we are involved in mission work abroad as well as locally, and that becomes a key focus for us.”

That’s one of the reasons he started the Bountiful Plant Ministries along with his cousin Ron van der Hengst and Estuardo Arriaga after a survey trip to Guatemala in 2007. The 501(c)(3), develops clinics, schools, churches, and orphanages in Guatemala, using plant farming to generate income and support services.

“We are a Christian family, so we do believe that it’s what’s commanded of us, as well as the fact that it is the right thing to do,” Van Hoven said, explaining there are also ministry efforts going on in Honduras and Nicaragua as well. “You do what you can do to help others.”

CHALLENGES

One of the biggest challenges American Color has faced post- COVID is the skyrocketing costs associated with virtually all things involved in the industry, including fuel, freight and equipment.

“The costs of plants have risen, not skyrocketed, so that dips into profitability unless you are operating efficiently,” Van Hoven said.

Increasing government regulations are also an annual issue, and though the greenhouse operator has overcome these by working through them or with them, it’s still time consuming, he admits.

“These are some of the things that has bitten greenhouse operators the last couple of years, and I think it’s going to continue to bite them,” Van Hoven said.

With the next generation of his family chiefly on board, Van Hoven has positioned American Color to continue thriving in the decades ahead.

Video Library

Video Library