Cover Story — Learn by doing

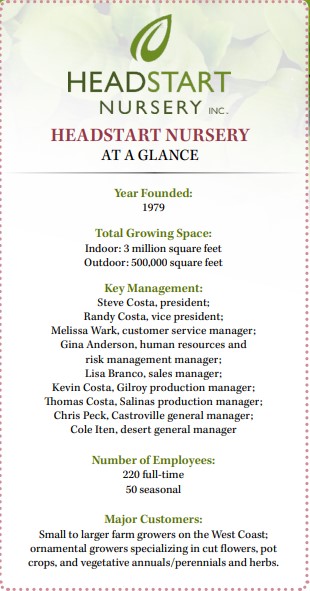

Headstart Nursery is owned by brothers Steve and Randy Costa, in partnership with garlic grower Christopher Ranch. The operation has grown into six different locations throughout California since its conception, but it originally began as a senior project in college.

Finishing up his senior year at California Polytechnic State University, Steve Costa was presented with an opportunity by a family friend to grow bell peppers. Don and Bill Christopher of Christopher Ranch needed to grow bell peppers in greenhouses, and Steve decided to make that his senior project to finish out his last year in college.

Steve built six greenhouses in Gilroy to grow bell peppers for Christopher Ranch, and Headstart Nursery was born in February 1979.

A successful first season resulted in more pepper orders and projects. Steve’s brother Randy soon joined the company, and together they built more greenhouses, then a few more in the years following to keep up with the increase in orders.

They quickly added cauliflower to the production schedule to fill in around pepper season and branched out into specialty flower crops soon after. In the early 1980s, California cut flower growers had a demand for snapdragons, lisianthus and asters, but the seed was difficult to germinate, so Headstart Nursery began providing them with a better start with plugs.

“Some of our local farmers that did some of the peppers had these side projects,” says Mel Wark, customer service manager at Headstart Nursery. “They would ask, ‘Hey, would you be interested in growing some lisianthus and delphinium and snaps and aster seed in your greenhouses and try it out that way, doing the same method of this plug transplant?’ We said yes, and that was a huge hit.”

So, they began working with local brokers in the early ‘80s to grow ornamentals and it expanded into a huge production. “We had houses and houses, hundreds of thousands of snapdragons here,” Wark says.

They soon became an industry leader in specialty cut flower plugs and have continued to build their ornamental offerings over the years.

Headstart became a player in the organic world in 1993, gaining organic certification by the CCOF (California Certified Organic Farmers) and becoming one of the first growers to provide organic vegetable transplants. Now, this accounts for about 25% of overall business — with production around 300 million certified organic transplants per year.

PRODUCTION

Pepper and watermelon continue to be a staple in the business and by dollar value are Headstart Nursery’s biggest crops. “We’re big in the pepper and watermelon game, and we send out over a billion plants a year of all crops, for sure,” Wark says. They also provide a large variety of other vegetable transplants like Brussels sprout, artichoke, celery and cauliflower; with the latter two being the largest crops by volume in production.

Ornamental plugs take a piece of the pie, too, but numbers are not as high as they used to be. When Wark began working in ornamentals at Headstart about 10 years ago, “we were doing much higher numbers than we are now, and that’s for a few different reasons,” she says. “A lot of people are doing their own direct sticking and, especially on the ornamental side, we’re sticking to crops that work best for the West Coast.”

Celery transplants are ready for planting.

Pepper transplants growing from seed.

Watermelon transplants are one of the top selling products at Headstart Nursery.

FILLING IN THE GAPS

During the winter months, most ornamental and vegetable production slows dramatically due to the cold weather of northern California and production shifts to the southern locations. Years ago, Steve and Randy began growing poinsettias at the Gilroy and Castroville locations to fill in the gap through the off-season. “While we do it to keep employees employed year round up North, it also is an opportunity to give back to our community. Poinsettias are sold to nonprofits and fundraisers in order for them to raise money for their organizations. The program continues to grow each year — in 2021 we sold roughly 78,000 plants and in 2022 we sold close to 100,000,” Wark says.

ALL HANDS ON DECK

Steve adopted the Cal Poly college motto and is always promoting “learn by doing,” encouraging everyone at Headstart Nursery to be involved and get their hands dirty as they grow the business.

Headstart wants to be known for its high quality transplants and exceptional customer service. “We invest heavily into our overhead, which we do in order to give a level of service that I don’t think other plug producers give. You call, you get an answer; you send an email, you get an answer. We have a team that is built to manage our big orders, and we have a specific customer service team that is for the small- to mid-sized growers, because all are important to us,” Wark says.

Headstart has a team that can support the years and years of growing that it continues to do.

“We have a huge production team, we have certain people in place at each location that play just such a specific role into making sure all procedures and protocols are met,” Wark says. We spend a lot of time and resources to anticipate and exceed our customers’ expectations. It’s not just about growing a great transplant, but meeting specific needs of each customer. Each order is unique and custom sown for every one of our customers.

“We make sure everything is correct at the time of entry. That way when it flows to our production team, it can do so without any hiccups,” says Wark. Then, the shipping department continues with its own protocols to keep everything on par through delivery.

TRIALING FOR SUCCESS

Steve and Randy have a sister company to provide a value added service to the greenhouse side of their business. Radicle Seed Co. is a dealer of high quality vegetable seeds and through their trialing efforts they are able to stay up to date on the latest varieties and genetics hitting the industry. They do a lot of trial work in customer fields when new products are available to gain important data and be able to provide better options to growers in the coming seasons. Headstart Nursery supports these efforts by growing the plugs for trialing.

On the ornamentals side, Headstart Nursery supports Danziger through yearly trials. “We actually hold the spring trials here [in Gilroy], which we’ve done for over 10 years. We’re a stop on the California Spring Trails route, so we grow all of their plants, all their finished stuff, to help them and showcase new varieties from Danziger,” Wark says.

SUSTAINABILITY

Headstart Nursery has incorporated growing technology products like Ellepots and PlantTape to reduce seed waste and labor costs, while also making transplanting easier for growers.

Water usage in California has been an important topic for years, as shortages continue to be an issue. Some growers have been denied access to water for farming usage on their land and were forced to cancel orders and close business. Headstart continues to be mindful of the amount of water they use daily and to keep consumption to a minimum without sacrificing plant growth.

Multiple locations have steamers that sanitize hard plastic and Styrofoam growing trays, so they are safe to be reused. “We’re always trying to use [trays] until they’re totally broken and can’t be used anymore,” Wark says. They also make sure to recycle materials when possible.

CAUSE OF COVID

Wark says it’s been an interesting few years at Headstart, especially with the new challenges COVID presented. Sales were not affected as much as they expected once the pandemic was in full force because many people were home, leading to an increase in home gardens. Any unsold plants were placed on an availability sheet that was turned out weekly and those plants were gone every single week, according to Wark.

“Sales-wise, we weren’t as affected as we thought we might be, but what we and the world had was supply chain issues. That was our biggest mountain to climb, just not being able to get anything. We couldn’t get any vermiculite, peat moss and trays,” she says.

They began trialing trays without vermiculite, using less peat moss, all different trials with crops to determine what they could do if they really did run out of these products. “It was quite worrisome, and then when we did get supplies, it was twice, three times more than what we normally would pay. So, then the costs went up, creating more difficult challenges that lead into pricing,” Wark says.

When Headstart customers have already sold the product to their customers at a specific contracted price, changing the cost mid-season due to these input increases isn’t happening, so ultimately Headstart takes the hit.

Diesel fuel increases have made challenges in shipping products through services like FedEx. The product in the box costs less than what the box alone costs to ship, so as a customer, does it make sense to pay those fees? Probably not. Headstart has been feeling the pinch in labor like most growers recently. “It’s hard with labor costs going up, as well as getting and keeping good labor.

“We put a lot of money into our overhead because we have people that have been working here for 20-plus years. We have people in the office that have been here 10-plus years. I think that’s because we put time and care into our employees that we have,” Wark says. “But when we’re busy and we’re trying to look for more help and more labor, it’s much different now getting a good laborer and then keeping the good labor.”

Delays in shipping have improved but are still not back to where they used to be pre-pandemic. “Supply chain issues continue to impact our business and it has caused us to be more proactive in our procurement of supplies, as well as customer outreach,” Wark says.

TECHNOLOGY

Headstart uses Picas software to keep everything in sync between locations for both ornamentals and vegetable transplants. This is a huge help when transferring products between the six facilities and allows the company to track important aspects of the business like how much it costs to transport between locations. “That helps us to also look at what crops could we move [to Gilroy] and not be grown in the desert so that we could cut some of those transfers out and save a little bit of money,” says Wark.

“Across the board, we just put a lot of procedures and protocols in place with our whole company, making sure that seed is here and available for our seed room to prepare it, get paperwork run, labels run, make sure our crews can get trays filled with media and ready to go, all that the week before. We’re really trying to operate much more systematically,” she says. As a small, family-owned business, it was much easier 40 years ago to plant orders within days of being placed by the customer. Today, many questions need to be answered before moving forward to avoid costly mistakes, says Wark. “Do we have the manpower? Do we have the time? Do we have the seeds? Do we have the trays? Do we have vermiculite? Do we have all the things? So, lead times have been a big challenge as well, just internally, changing the mindset of making sure that we aren’t operating off of 911s all the time.”

TRANSITIONING FOR THE FUTURE

“I remember being at Spring Trials and I would say, ‘We can do it all. We can do anything. Here are our programs, and this is just a starting point.’ But if you have a customer who wants a different crop or wants the same crop but in a different tray size, we can do it,” Wark says.

As good as it feels to say you can accommodate any customer request, time showed Wark that it was better to concentrate more on growing plugs for West Coast growers, especially in ornamentals. “I got pushed into it a little bit because freight was just astronomical, and it killed me to invoice something where the box alone was more than the product inside of it, sometimes double what the product was inside of it,” she says.

Headstart now focuses a lot of effort on growing products that will benefit and make sense for West Coast growers. Shipping rates are better because it’s more local, and they can often deliver the orders themselves, keeping prices at a reasonable rate. Changing the structure of the ornamental department and how it operates has ensured that the crops they are growing are being managed well and customers receive the best quality.

Today, Randy’s sons Kevin and Thomas, and Steve’s son Kyle are all working for the family business. They’ve grown up around Headstart Nursery and are excited to be a part of the group. Kevin manages production at the Gilroy facility, Thomas is production manager in Salinas, and Kyle works in seed procurement.

Everyone on the Headstart team has a specific role that is crucial to the overall success, not just at each location, but collaborating as a whole. Production meetings take place every week to keep everyone in the loop and connected, allowing for discussions about current issues, what’s going well, reminders, etc. “I think creating a place where we can just continue to strive and do better and keep doing what we love and do it really well,” Wark says, “that’s how we’re going to continue for another 40 years, hopefully.”

Sidebar: Location, Location, Location

The main hub in Gilroy, California, is where it all began and where everything is still initiated from today. “All seed is sent here to Gilroy where it’s inventoried, it’s allocated, it’s put into our tracking system, and then it’s also stored here in our seed room, which is a temperaturecontrolled environment. Even though we do sow seed on a sow line at two or three other locations, we still have all the seed come here to the main hub first,” says Mel Wark, customer service manager at Headstart Nursery.

When Headstart began selling plants to growers farther south in the desert areas of California, they were loading trucks and transporting plants down often. So, in 1993, Headstart started building greenhouses in Mecca in the Coachella Valley. This gave them the ability to grow during the winter months, as the desert environment was much different than Gilroy, with higher light and warmer temperatures year-round. Eventually another southern location was opened in Thermal, providing more space to grow throughout the year and allowing service to the southern areas of California, Arizona, New Mexico and Nevada.

Three more locations opened in 2011 in Castroville and Salinas. Here, the weather is fairly mild and cool allowing for production expansion of cool weather crops like artichoke and gerbera. “Steve was really strategic in the way of picking places that would be ideal for growing conditions,” Wark says.

Being able to shift production between locations enables Headstart the flexibility to grow high quality plants all year long.

For an enhanced reading experience, view this article in our digital edition by clicking here.

Video Library

Video Library