A century of growing

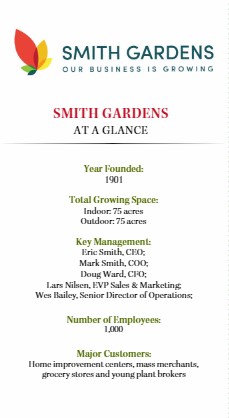

Smith Gardens made its home on the West Coast 122 years ago. Today, it’s owned by the fourth generation — brothers Eric and Mark Smith. The business currently employs 1000 people, has four facilities, 75 acres of climate-controlled greenhouses and 75 acres of outdoor growing space. The large operations make delivering 20 million finished containers across Washington, Oregon, Idaho and Alaska, and 40 million young plants across North America a successful endeavor.

In 1901, Harry Smith immigrated from Scotland and purchased 40 acres of farmland overlooking Bellingham Bay in Washington. Smith Gardens was born here and opened its doors as a vegetable producer for local markets. The property remains a homebase for Smith Gardens and continues to be used primarily for production of annuals now. Harry’s two sons, Andy and Russell Smith, eventually took over the business and began to diversify by slowly adding flower starts in the spring in the 1950s.

Then Interstate 5 (I-5) was completed in Washington in 1969, which connected the entire West Coast allowing year-round access for fresh produce to be delivered from California all the way to the northern border of the U.S. This prompted a necessary shift in the focus of Smith Gardens. In the 1970s, the third generation took over Smith Gardens. Terry Smith understood the need for expansion and implemented changes to its production operations, pivoting to bedding plants and potted flowers as its main focus. During this time, home improvement stores were starting to build garden centers. “It was a real point of separation — nurseries that stayed ‘retail’ onsite, versus those nurseries who strove to deliver on demand flowers to big box stores,” Eric Smith, CEO of Smith Gardens, said. “Our father had the foresight to ‘go big’ and begin shipping, versus keeping a ‘flower stand’ on the farm.”

DELIVERY ON DEMAND

As the demand from big box stores grew, so did Smith Gardens. In 1988, 60-acres were purchased in Marysville, Washington, followed by the purchase of the Aurora, Oregon, facility over the next decade.

“Finally in 1999, we vertically integrated with the purchase of Pacific Plug & Liner in Watsonville, California, converting it from cut-rose production to young plants,” Smith said. “We saw an opportunity to take advantage of the area’s sunny winters and cool summers, and thus Pacific Plug & Liner (PP&L) was born.”

Today, PP&L provides young plants for brokers and growers in North America, as well as the needs of Smith Gardens.

TODAY’S TEAM

“Our greatest strength is in our team’s ability to adapt and grow, which comes from our intentional development of individuals,” Smith said. “It’s important that each person on our team understands why their role is important and what their purpose is in the company — it’s best when teams can put this in their own words and discover how can we be better.”

The Smith Gardens team attends an annual spring kick-off event, where it’s not uncommon for 30 to 40 individuals to be introduced in their new role from internal promotion or new to the company. “Our motto since the 1960s has been ‘Our business is growing’ and, of course, we are in the business of growing flowers, but we are even more so in the business of growing people,” Smith emphasized. “When we do these two things well, we create opportunities.”

Smith shared as Smith Gardens continues to grow in size, it will continue to grapple with: “I can’t do it all,” and “I can’t do it alone.” But this is where development plays a crucial role.

“Last year, we created the position of operations director. Wes Bailey, our Aurora, Oregon, site manager for the past 17 years was promoted into that role,” said Smith. His position was filled by the shipping manager, Andrea Avila-Aragon, whose position was taken by Salvador Ramirez, the selecting supervisor, and his position was given to Georgina Ascencio. “This one change opened the door for a multitude of employee growth opportunities.

“Examples like this are all over our company. Our greatest strength really is in our team and our ability to develop experience within them so that they are ready for our next opportunity to grow and theirs as well,” Smith shared.

CONTINUE CLIMBING

Smith Gardens remains focused on providing finished product to home improvement centers, mass merchants and grocery stores as well as shipping quality young plants across the U.S. and Canada.

Investing in data systems that result in lean processes and increase efficiency throughout the company are key to success. Scan-based trading, the use of data and the ‘Linerbility’ process from PP&L are great examples of this.

SCAN-BASED TRADING

In 2006, scan-based trading began and now 75% of the business is conducted using some form of it. Scan-based trading puts the control of product flow into the Smith’s teams hands, allowing employees to manage forecasting, product readiness, delivery, care and display of finished goods at the big box retailers. This helps drive sales, increase sell-through and reduce waste.

Smith explained the use of data in forecasting sales and scheduling production sets them up for success. “While we end up forecasting units, we really have our eye toward retail dollars scanned so as to take into account price elasticity and promotions that drive footsteps in stores,” he said. “Each year there are changes in container configurations, promotions, retail price points, making each successive season a unique forecasting event. The last three to four years of history guide us, but it is more about where the market is going, consumer trends, new products that supplant incumbent scans that drives our forecasting.

“We remind ourselves that there is a science of bringing data to bare on decisions, but also an art of predicting the success of new configurations and varieties and the ability to flex with supply chain challenges,” he said.

LINERBILITY

PP&L’s online availability process was built in-house and named Linerbility. The program increases efficiency throughout the company, improves methods, and tracks both supplier inventory and Smith Gardens inventory on the bench in real time.

HOW IT WORKS

Product availability is pushed automatically to customers, while employees grab variety availability information from suppliers and send it through the crop planning system, which then shows how much of a product Smith Gardens can grow based on the supplier’s availability. This information is automatically put into the online availability, Linerbility.

“This system has greatly reduced both our risk and unsold extras as we no longer purchase any inputs until an actual young plant order is placed. We, of course, do limited speculation on our bigger programs with long lead times,” Smith detailed.

Smith Gardens sources unique and quality genetics through breeder relationships, often working with smaller breeders looking to break into the North American market. PP&L steps in to share knowledge and act as a guiding force to bring these new genetics into the market.

WEATHER AND WAGES

Two big challenges come to Smith’s mind when talking about issues that face the company today: weather and wage inflation.

Floods, hailstorms and tornados have caused destruction and crop loss for many over the years, but these catastrophes are also happening to our employees and their families, Smith noted.

“This year we witnessed this firsthand with the incredible floods in California. Several of our staff were directly affected, with forced evacuations and property loss. It was important to us to support our team through these events,” he said.

The margin squeeze due to wage inflation, increased materials cost, energy and transportation have been another big challenge. Energy goes up and down, but the labor for young plants, hardgoods and transportation continues to climb. “Long-term, our real ability to combat wage inflation is to invest in a culture of continuous improvement, planning software, and automation that gives us better visibility to data and the ability to plan accordingly,” he said.

Let’s not forget the impacts still being felt from the pandemic. Between March and April 2020, Smith Gardens went from building inventory for spring, to holding daily health briefings and implementing COVID protocols.

“When two of our retailers started limiting the number of shoppers in their stores, we thought to ourselves, ‘This will be how we end our careers in the flower business,’ but two weeks later we were proved wrong,” he said. “The next two years ended up being the infusion that our industry needed to capture a renewed interest in staying home and gardening — hopefully for years to come,” he said.

STRATEGY WITH SOFTWARE

Smith Gardens uses planning software to organize production and shipping, and cut down on wasted hours. This removes waiting and reworking time, helps balance crew workloads, directs crews on smart routes and reduces double handling and travel time. Automation has improved how products are moved and spaced, while also reducing lift-twist/sprain-strain injuries and associated workers compensation costs.

“These investments have allowed us to increase our per unit productivity 37%. We had to because our total cost per hour of labor climbed 43% since 2017 from $18.84 to $26.99 in 2022. This resulted in our ability to control our cost per unit of production,” Smith detailed. “We have also made capital investments transforming 75% of our total indoor space and 65% of our outdoor space to reduce human touches in laydown and spacing.”

He also shared that Smith Gardens is now rolling racks directly into both indoor and outdoor bays, which lessens the number of times a product is touched and moved at shipping time. These types of improvements can be costly — retrofitting floors for $5 a square foot and building modern greenhouses for $30 to $35 per square foot — but the long-term investment will help mitigate wage cost increases in the future.

THE FUTURE IS NOW

Smith Gardens continues to approach its second century with continued development for both the company and its employees, and a commitment to building capacity to serve its customers growth ambitions.

“It is up to us to encourage the next generation,” Smith said. Which is why Cultivating the Future (CTF) was created by Smith Gardens in 2015. This program works with 25 primary and secondary school districts, and community colleges and universities horticulture programs, bringing the industry to students aged 5 to 25.

“It is up to us to encourage the next generation,” Smith said. Which is why Cultivating the Future (CTF) was created by Smith Gardens in 2015. This program works with 25 primary and secondary school districts, and community colleges and universities horticulture programs, bringing the industry to students aged 5 to 25.

“We help their programs succeed and show them the career possibilities that lie within the industry,” he shared. “We are seeing the benefit of CTF, having several students who participated in the program join our team full-time and at a management level.”

Smith Gardens also fosters a more successful customer experience through genetic research and development, trialing, traveling and trying new concepts to bring outstanding quality to the industry. This year will be the 9th Annual Trial Garden Event at the Smith Gardens trials facility in Marysville, Washington.

“We continue to add automation where we can as well as integrating and improving data through smart mobile software systems,” Smith said. “We will focus our efforts on building a culture of continuous improvement and creating a great place to work.”

For an enhanced reading experience, view this article in our digital edition by clicking here.

Video Library

Video Library