How Much Does It Cost to Sanitize Your Water?

Plant pathogens, algae and biofilm are problems commonly associated with irrigation water. The water molds Pythium and Phytophthora are examples of pathogens that can spread from plant to plant in water. Ponds and recirculated water sources are more likely to harbor or spread plant pathogens than well and municipal water.

Algae is especially problematic in warm, humid environments such as propagation greenhouses, and accumulates on the surface of growing media, inside pipes and floors. Biofilm is a combination of bacteria, algae and other microbes that accumulate in main irrigation lines and causes clogging of emitters.

Growers rely on water sanitizers to minimize the risk of crop loss and reduce labor cost from plant disease, algae, and irrigation emitter clogging from biofilm. We analyzed treatment cost and found a wide variation between water sanitation options used by greenhouse growers.

Sanitation Options

Water sanitation options include chemicals (activated peroxygen, hydrogen peroxide, bromine, chlorine, chlorine dioxide, copper, quaternary ammonium and ozone), physical treatments (membrane filtration, ultraviolet radiation and heat treatment), and biological options (slow media filtration, constructed wetlands and biopesticides).

The ability of a treatment technology to control microbes depends on the target organism. For example, infective spores of Fusarium are more resistant to sanitizers than Pythium zoospores. Efficacy tends to increase as the applied concentration and contact time increase. Poor water quality (for example a high level of suspended solids and turbidity, a high concentration of salts, high pH, as well as low temperature) typically reduces the disinfestation strength of water treatments. You can search an online database of research studies on water treatment by using the Waterborne Solutions tool at cleanwater3.org/gsearch.asp.

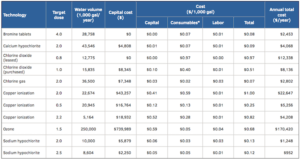

Table 1: The cost to treat irrigation water based on data obtained from commercial greenhouses.*

The Cost of Sanitation From Commercial Greenhouses

We estimated the cost of water sanitation based on data obtained from commercial greenhouses (Table 1). The size of the surveyed operations varied widely, and the final cost can be affected by economies of scale. Costs were calculated per 1,000 gallons of water treated.

- Capital costs refer to purchase of equipment, shipment and installation. We used a 10-year linear depreciation for copper ionization and ozone equipment, and a five-year depreciation for other equipment such as chemical injectors. The capital cost per 1,000 gallons equaled the upfront investment divided by depreciation years, divided by the water volume treated (per 1,000 gallons).

- Operational costs represent consumables (such as chemical reagents or electricity) and labor required to run and maintain the equipment.

- Total costs represent the sum of the capital plus operational costs per 1,000 gallons of water treated.

The total cost of water treatment for the surveyed greenhouses ranged between $0.07 for chlorine gas to $1 per 1,000 gallons for copper ionization (Table 1). Labor was up to $0.03 per 1,000 gallons for all treatments, except ozone which required more skilled management than other technologies.

Bromine was a low-cost treatment at only $0.08 per 1,000 gallons. This system consisted of a basket placed where return water flowed from sub-irrigation floors into holding tanks, with bromine tablets being dissolved as water flowed through the basket (Figure 1, pictured at top of page). Therefore, the only cost was the tablets and labor to check and add tablets. This simple system had an uncontrolled dose and is unlikely to be effective at controlling pathogens. We estimate the applied dose was approximately 4 ppm of boron, which is considerably lower than the dose previously published in research on plant pathogen control.

Chlorine based-products had a low total cost of up to $0.13 per 1,000 gallons, which favors the use of chlorination when large water volumes require treatment. Chlorine is also the treatment technology that has received the most scientific testing for pathogen control. Chlorine is available in several ways, including liquid sodium hypochlorite (Figure 2a, pictured above left) and chlorine gas (Figure 2b, pictured above right), solid calcium hypochlorite, concentrated hypochlorous acid and electro-chemical activation (ECA).

The capital cost of copper ionization systems (Figure 3) varied depending on the scale, equipment manufacturer and ionization equipment design. The most expensive option was a customized system to treat the water inside holding tanks. In lower-cost options, irrigation water passed through an inline copper ionization unit.

Chlorine dioxide systems generated concentrated chlorine dioxide onsite from two chemical components, which were then dosed at a lower concentration into the irrigation line (Figure 4). One operation that purchased the equipment had a higher capital cost compared with an operation that leased the equipment. However, the consumable cost (which consisted of annual service fees and chemicals) was lower when purchasing the equipment. Equipment leasing provides the opportunity to assess efficacy of equipment prior to purchasing equipment, thereby reducing financial risk.

Ozone is an integrated system with high capital investment that includes equipment to pre-filter, pump, concentrate oxygen, generate ozone, mix the ozone into solution and control the dose. The main consumable cost associated with ozone was electricity.

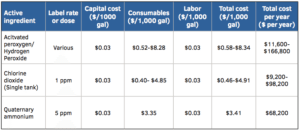

The Cost to Sanitize 20 Million Gallons of Water Per Year

We standardized water treatment cost for a hypothetical operation using 20 million gallons per year so we could compare injected chemicals (activated peroxygen, chlorine dioxide and quaternary ammonium chloride, Table 2). Twenty million gallons was approximately the median water volume used in our grower survey. We estimated the consumable cost based on the low continuous label rate, based on the largest available container size of the sanitizing chemical.

The cost to sanitize 20 million gallons of water per year with the three injectable chemicals ranged from $9,200 to $166,800, depending on the product (Table 2). The majority of the cost for these technologies was from consumables, and the chemicals could all be applied with simple and low-cost chemical-injecting pumps or dilutors. The cost of competing injectable sanitizing agents with similar active ingredients varied by brand by more than a factor of 10.

Technologies that have a high consumable cost are more suited to operations treating a low water volume, for example in an operation that only treats water used in a mist propagation zone where high water quality is particularly important. In contrast, capital-intensive technologies with low consumable cost have advantages when large volumes of water are treated, where all incoming water is centrally treated.

Take Home Messages

- When treating large water volumes, select treatments that have a low cost per 1,000 gallons.

- When treating small water volumes, an injectable chemical may be simple to install and manage despite the higher consumable cost.

- Where available, consider leasing equipment to reduce capital expenditure.

- With complex equipment, ensure there is a service agreement for safe and effective operation.

- Do your research to evaluate different competing products with similar active ingredient.

- Ensure equipment is correctly sized for your operation to avoid excess cost or incorrect dosing.

- Cost is only one of the criteria when selecting a water sanitation method. Make sure it has been proven to be effective for your water quality issue, is safe and easy to use, meets regulatory requirements, and does not cause other issues such as phytotoxicity.

In the next article, we will present the cost of water sources. By adding the cost of water sources, water- soluble fertilizers, filtration and sanitation, you can estimate the true cost of irrigation water.

Acknowledgements. Thanks to funding support and collaboration from industry partner the Floriculture Research Alliance.

Click here to read part one of this series on the cost of irrigation water.

Video Library

Video Library