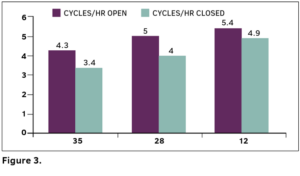

SGAFT: Energy curtain performance

The Small Greenhouse and Farm Technology (SGAFT) project is collaborating with GPN for a series of research reports and articles on small scale technology application. SGAFT’s mission includes providing small greenhouse and farm operators with technology guidance tailored to their scale of operation.

This article’s research was conducted by Konjoian’s Horticulture Education Services and designed to better understand energy curtain performance in a small greenhouse setting. This report transitions to the SGAFT website (sgaft.com) with additional pictures, data graphics and discussion.

CURTAIN STUDY 2023

Six overnight data-generating sessions occurred Feb. 25-March 19, 2023. Yes, you read that correctly, six all-nighters were pulled over three weeks, each thirstily stimulated by caffeine followed by a day or more of recuperation. It was a fun experience that generated pages of spreadsheet data. The first part of the study covered three nights: Feb. 25, Feb. 27 and March 1. Main variables included three different outdoor temperatures and alternating energy curtain positions between open and closed through the night. The greenhouse temperature was controlled by Bartlett Instrument Company’s Climate Boss system. The curtain fabric, Svensson’s Tempa 5557 (55% shade, 57% heat retention), was part of a Wadsworth Control Systems curtain package.

The second part of the study included a third variable of alternating between Climate Boss and a mechanical thermostat through the night and is presented on the website.

The high-efficiency Modine propane fired hot air furnace and curtain in a closed position. Each furnace cycle included three manufacturer presets: 20 seconds between thermostat heat call and ignition, 30 seconds between ignition and heat exchanger fan start and two minutes post-ignition fan cool down. Total ignition (burn) time and total fan run time varied for each cycle and were recorded. Also recorded were the cycle start and end time (duration) and time between cycles (frequency).

Air temperature was monitored at two locations, 18” above the bench and 6” above the curtain, at the start and end of each furnace cycle. Staged pair of sensors monitored temperature above and below the curtain as the curtain opened after a closed session.

The above/below curtain temperature gradient shown is 46.0º F/62.7º F, the post-opening period called a morning cold air dump.

Following each curtain position change (open or closed) the first heat cycle served as a transition cycle and was excluded from data analysis. Regarding bench temperature, this cycle neutralized the cold air dump following opening. Regarding above curtain air temperature, the transition cycle allowed for cooling of the warm air after closure. Excluding transition cycles more closely simulates continuous curtain use through the night.

OUTDOOR TEMPERATURE

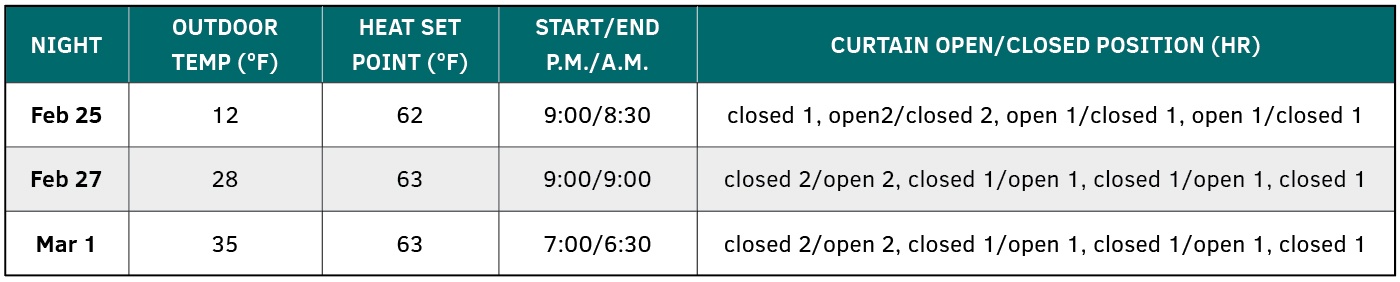

Three parameters in Figure 1 were averaged over both curtain positions, open and closed, to present the effect of outdoor temperature on greenhouse heating. Total minutes of furnace burn (ignition) time and the number of furnace cycles are presented on a per hour basis along with the average burn time in minutes per cycle. Graphs appear in order of descending outdoor temperature: green-35º F, blue-28º F, and red-12º F.

Three parameters in Figure 1 were averaged over both curtain positions, open and closed, to present the effect of outdoor temperature on greenhouse heating. Total minutes of furnace burn (ignition) time and the number of furnace cycles are presented on a per hour basis along with the average burn time in minutes per cycle. Graphs appear in order of descending outdoor temperature: green-35º F, blue-28º F, and red-12º F.

The left set of bars shows total minutes of burn time/hour with burn time (fuel consumption) increasing as outdoor temperature decreased from 35º F to 28º F to 12º F. Burn time increased from roughly 10 to 13 to 16 minutes/hour as outdoor temperature fell. Between the warmest night (35º F) and coldest (12º F) the total minutes of burn/hour increased 59% (10.3 to 16.4 minutes).

The center set of bars presents furnace cycles/hour and shows cycles increased as outdoor temperature decreased. As temperature dropped from 35º to 28º F the furnace required 0.6 of an additional cycle to maintain temperature and another 0.7 of a cycle as temperature dropped from 28º F to 12º F. The right set of bars shows average cycle burn time in minutes, which also increased as the temperature fell but less dramatically. Allowing for rounding of numbers, within each temperature minutes of burn time/hour = cycles/hour x average burn time/cycle.

CURTAIN OPEN VERSUS CLOSED

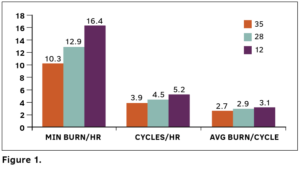

Figure 2 shows total minutes of burn/hour for the three-night temperatures with the curtain open (purple bars) versus closed (green bars). At 35º F the curtain open versus closed split was 11.5 versus 9.1 minutes, a 21% reduction. At 28º F the 14.5 versus 11.3 split was 22%, and at 12º F the 18.2 versus 14.5 split was 20%. Closing or “using” the curtain resulted in 20-22% less fuel consumption.

Figure 2 shows total minutes of burn/hour for the three-night temperatures with the curtain open (purple bars) versus closed (green bars). At 35º F the curtain open versus closed split was 11.5 versus 9.1 minutes, a 21% reduction. At 28º F the 14.5 versus 11.3 split was 22%, and at 12º F the 18.2 versus 14.5 split was 20%. Closing or “using” the curtain resulted in 20-22% less fuel consumption.

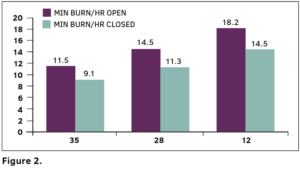

Figure 3 shows the number of furnace cycles/hour for the three-night temperatures with the curtain open or closed. At 35º F and 28º F closing the curtain reduced the number of heat cycles by about one cycle/hour. At the lowest temperature of 12º F, the curtain reduced the heat cycles by one half of a cycle/hour.

temperatures with the curtain open or closed. At 35º F and 28º F closing the curtain reduced the number of heat cycles by about one cycle/hour. At the lowest temperature of 12º F, the curtain reduced the heat cycles by one half of a cycle/hour.

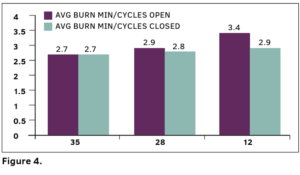

Figure 4 presents minutes of burn time/cycle which was minimally affected through the warmer nights of 35º F and 28º F by curtain position. However, through the coldest night, 12º F, cycle burn time increased by half a minute when the curtain was open versus closed. Reciprocally, during warmer nights closing the curtain did not significantly reduce the furnace’s burn time/cycle but on the cold night closing the curtain resulted in a shorter cycle time.

Figure 4 presents minutes of burn time/cycle which was minimally affected through the warmer nights of 35º F and 28º F by curtain position. However, through the coldest night, 12º F, cycle burn time increased by half a minute when the curtain was open versus closed. Reciprocally, during warmer nights closing the curtain did not significantly reduce the furnace’s burn time/cycle but on the cold night closing the curtain resulted in a shorter cycle time.

CONCLUSION

Energy curtain use in this small greenhouse study reduced fuel consumption by 20-22%. Differences were observed over both main variables; three outdoor temperatures (35º F, 28º F, 12º F) and two curtain positions (open versus closed).

This report continues at sgaft.com with the second part of the study. Additional pictures and data are discussed as well as an interpretation of the entire study’s science from my perspective as a commercial greenhouse owner/operator.

Video Library

Video Library