Technology and Automation Help Grow Produce and Profits

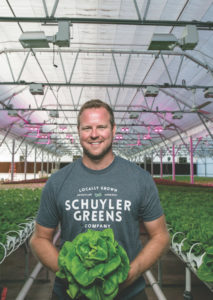

John McMahon, founder and farm manager at Schuyler Greens Co. in Schuyler, Virginia, grew up on a farm and knew he wanted to eventually start his own growing operation.

“The reason I decided to focus on greenhouse production rather than traditional field production was where my MBA in finance came in,” McMahon says. “I always wanted to be an entrepreneur and I wanted to be involved with some aspect of farming. If you are talking about customers and different farming operations, one of the biggest issues with controlled environment agriculture is growing locally.

“When I talked with different customers including restaurants, schools, whoever the end user was, they wanted to buy locally, but they couldn’t find a reliable supplier year-round. When I was doing my homework before I started the operation, I learned a greenhouse offered me the opportunity to control a lot of the variables and produce year-round. I can produce greens on a weekly basis.”

McMahon started his business in 2015 with a 1,500-square-foot Nexus Grand Teton gutter-connect greenhouse. He has since expanded the facility to around 20,000 square feet.

“I started with a gutter-connect greenhouse because it was modular and allowed me to expand in any direction I wanted,” he says. “It was more capital upfront, but it enables me to expand in different directions. If it was free-standing, then a lot of the environmental controls that were installed would be worthless.

“It seems like every nine to 12 months I put up another greenhouse bay. I started very small, but I quickly realized the economies of scale that I needed to be big enough in order to get into some bigger institutional accounts. I have to be able to produce the volumes they are looking for.”

AN EVOLVING PRODUCTION FACILITY

The type of production system McMahon is using has evolved as his facility has grown in size and as he has gained more experience as a grower.

“I started with nutrient film technique (NFT) and am now moving into deep water rafts mainly for automation and nutrient solution temperature control,” he says. “A lot of our bigger customers want cut product including salad mixes and baby greens. I can mechanize with a raft system easier. Right now two-thirds of the operation is NFT and one-third is rafts. By the end of the year, two-thirds will be rafts. We will likely focus the remaining NFT system on head lettuce production as it requires less labor to harvest than baby greens.

“My goal is to be as efficient as possible. Labor is the biggest expense in the greenhouse and that’s the same on farms in general. To be viable we need to automate as much as possible. With a greenhouse facility we do that with environmental controls and fertigation. Now we are automating the production. We won’t require as much physical labor for transplanting, fertilizing and harvesting.”

McMahon has also installed supplemental lighting to improve the production of many crops.

“Originally I started with 1,000-watt high pressure sodium lamps,” he says. “I have switched over mostly to LEDs. The majority of them are Illumitex Power Harvest LEDs. I also have some LumiGrow LED fixtures.

“Initially I thought I would only use the lights during the winter. During summer the days are long enough that we actually want to slow the plants down a little bit. We use the LEDs during the summer to increase the anthocyanin pigment levels in red leaf lettuce. The LEDs help to increase the color from a marginally red to a deep red. This is more for cosmetic purposes. During the winter we’re pushing the plants as hard as we can with supplemental light. We have certain daily light integrals (DLI) that we are trying to hit.”

DATA, AUTOMATION ARE CRITICAL

McMahon says his business education and farming background have provided him with a unique skill set to look at his operation differently than other growers.

“Having a farm work ethic enables me to run a bulldozer and do excavation work,” he says. “With my MBA in finance I’m able to do business modeling and budgets. When I look at everything in the greenhouse, the most valuable part is the data. Our whole greenhouse is in the cloud. I’m trying to model all of the data and identify trends.

“I’m working with different companies to do machine learning or artificial intelligence so we can use our data to make our controllers be more intelligent so they can anticipate changes. I try to break down every process and try to make it better. I’m not married to a certain way. The future is automation and I’m trying to shorten that curve for us.”

“We have everything online,” he says. “We use Autogrow for EC and pH monitoring. The company has a new application called Explore. It is cloud-based and combines monitoring and data analytics.

“Originally I worked with a freelance developer to upload our various data streams into an Amazon web server which I used as a data warehouse. I have modeled the data in an application called Tableau to identify trends and track our performance. I’m now using Explore. I can get on the website and see everything the greenhouse is doing whether I’m there or not and make adjustments remotely. The greenhouse is operating 24/7.

Monitoring the greenhouse enables me to respond during the middle of the night whether that has to do with shutting something off or turning something on. I consider that to be an invaluable form of insurance.”

FOCUSED ON FOOD SAFETY

McMahon is looking to add more products to increase his company’s revenue streams. “Even though we are a small farm our yields are much higher than other local small farms,” he says. “We’re growing year-round. Anything we grow I try to grow in large volumes in order to serve larger markets like distributors, educational institutions, etc. There are so many small farms that go to smaller customers like restaurants and farmers markets. I’d rather deliver a pallet of product to a distributor rather than having to sell at a farmers market not knowing whether I’m going to be able to sell all my product.”

“But the differentiation isn’t always the product. We are GAP certified to service larger markets with larger volumes of product. If a vegetable grower doesn’t have GAP certification then he’s going to be out of business. It’s headed that way. When there are food recalls and newspaper articles saying don’t buy romaine lettuce, that can have devastating effects. If that happened to me I’d be out of business. I’m not big enough to handle those kinds of losses. Whether a grower is producing indoors or in the field, food safety is first and foremost the most critical issue.”

CONSTANT IMPROVEMENT

McMahon’s best advice to new growers is to fail early and to fail often, but not too often.

“I had some big failures including catastrophic equipment failures and lost a lot of plants,” he says. “It was brutal going through those failures, but it made our systems, processes and procedures much more redundant and robust. I read a lot, including academic research studies about plants. That is why I am doing a lot of work with LEDs. I look at CEA research all of the time and have developed relationships with researchers like Neil Mattson at Cornell University.”

“Even though we are small compared to a lot of other commercial greenhouse vegetable growers, we are trying to push the envelope in terms of how we grow the crops. You don’t have to be the biggest grower to be competitive, but you better be good at what you do. I’m always trying to learn as much as I can. I’m driven to be better.”

For more information: Schuyler Greens Co.; 844.351.3276; farm@schuylergreens.com;www.schuylergreens.com.Follow Schuyler Greens at@schuylergreensco on Instagram

Video Library

Video Library