Oasis Grower Solutions reveals carbon footprint assessment of foam substrate

Oasis Grower Solutions, an engineered growing media company and division of Smithers-Oasis, recently released the results of a cradle-to-grave carbon footprint assessment of its OASIS AeroMax engineered foam substrate.

Launched in 2021, OASIS AeroMax was the first in a line of ultra-low density, next-generation OASIS AeroFamily substrates that represent a new core technology for the company’s engineered growing media.

Launched in 2021, OASIS AeroMax was the first in a line of ultra-low density, next-generation OASIS AeroFamily substrates that represent a new core technology for the company’s engineered growing media.

Oasis Grower Solutions director of global grower operations and research Vijay Rapaka, Ph.D., lead scientist in the development of the substrate technology, explained that the carbon footprint assessment was an important next step after the new technology’s 2021 launch, particularly with the substrate’s focus on precision hydroponics and controlled-environment agriculture (CEA).

“Sustainability is very important to us at Oasis Grower Solutions and Smithers-Oasis. We understand how important it is to our customers, too. It’s one of the most commonly asked questions we hear. We felt a responsibility to educate ourselves and our customers,” Rapaka said. “CEA is built on sustainability, and we want to do our part. We wanted to really understand the big picture surrounding the sustainability of this new engineered substrate and its carbon footprint.”

OASIS AeroMax Carbon Footprint Assessment Details

OASIS AeroMax Carbon Footprint Assessment Details

Conducted by U.K.-based Carbon Footprint, Ltd., the carbon footprint assessment focused on the 2021-2022 production period. In addition to assessing the cradle-to-grave product carbon footprint of OASIS AeroMax, the study also assessed two peat products for comparison: gravity filled loose plugs (OASIS Fertiss gravity-fed stabilized peat plugs) and pressed peat.

To determine the greenhouse gas emissions associated with OASIS AeroMax and the two peat products, Carbon Footprint Ltd. conducted a full assessment following established cradle-to-grave carbon footprint boundaries for each product, including the following:

- extraction, processing and transport of raw materials

- manufacture, processing and packaging of product (including offcut waste)

- product distribution, usage and disposal

- relevant transport/freight elements

OASIS AeroMax Carbon Footprint Assessment Results

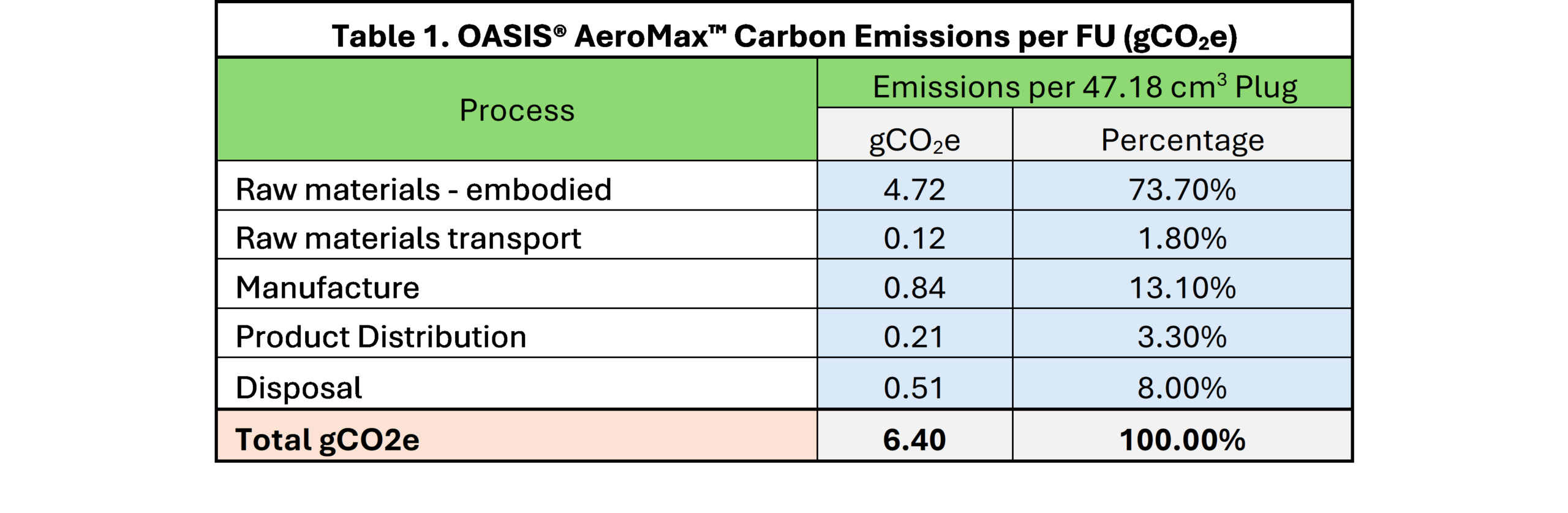

The results of the product carbon footprint assessment, specific to OASIS AeroMax substrate, can be seen in Table 1 below.

The cradle-to-grave carbon emissions of OASIS AeroMax engineered foam substrate were assessed to total 6.40 grams of CO2 equivalent emissions per functional unit (FU) — one 47.18 cm 3 plug (3.175 cm x 3.90 cm x 3.81 cm). As noted, embodied emissions of raw materials accounted for more than 70% of that total.

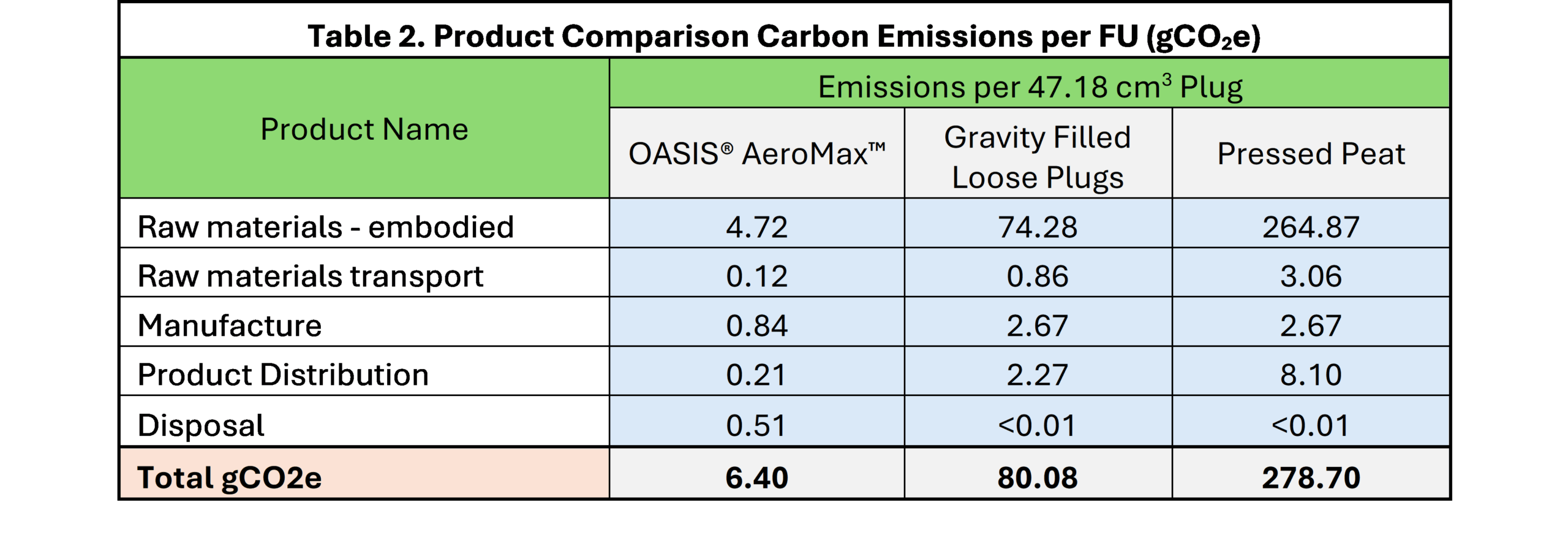

The results of the carbon footprint assessment’s plug-to-plug product comparison can be seen in Table 2 below, again based on the Functional Unit of one 47.18 cm 3 plug. The cradle-to-grave CO2 equivalent emissions of OASIS AeroMax substrate, gravity filled loose plugs and pressed peat were assessed at 6.40 grams, 80.08 grams and 278.70 grams respectively.

As shown, the CO2 equivalent emissions for Pressed Peat were assessed at 278.70 grams per plug, more than 40 times higher than an equivalent OASIS AeroMax plug. Gravity filled loose plugs, at 80.08 grams of gCO2e per plug, were assessed as 12.5 times higher than an equivalent plug of OASIS AeroMax engineered substrate.

Rapaka said the results surprised even the Oasis Grower Solutions RI&D (research, innovation & development) team. But the carbon footprint assessment represents a starting point, not an end in itself.

“We’re going to continue to work on finding ways to lower the carbon footprint of our next-generation engineered OASIS AeroFamily substrates even more — and our gravity filled loose plugs, too. And we’ll use this information to help guide how we develop the next generation of products,” he said.

For more information about the OASIS AeroMax carbon footprint report and why Oasis Grower Solutions engineered substrates are environmentally sound choices for precision propagation and production, you’re invited to contact the company at info@oasisgrower.com.

About Smithers-Oasis:

About Smithers-Oasis:

Smithers-Oasis’ global expertise in the plant and flower business stretches from propagation to presentation. With locations in more than 19 countries and resources around the world, Smithers-Oasis manufactures and markets floral foam and floral media, postharvest products, growing media, floral sprays and dyes, and flower arranging supplies for the floriculture and horticulture industries. OASIS, FLORALIFE, and DESIGN MASTER are three of the company’s most recognized brands founded in 1954, 1938, and 1961, respectively. With 70 years of experience in foaming technology, Smithers-Oasis also manufactures and markets specialty foams for a wide variety of applications including temperature control packaging, cast-alternative impression, absorption, and molding. The company’s driving purpose is Improving Lives Worldwide. Smithers-Oasis, a privately owned company, is headquartered in Kent, Ohio.

Video Library

Video Library