Software is to a Company Like Soil is to a Plant

The grower industry is competitive, capital intensive and dependent on good weather. Growers must improve efficiencies and lower costs to fight shrinking margins. Software that is specifically built for growers, not widgets, makes all the difference in trying to achieve these goals.

Grower software, like all software, is ever evolving. There will never be a day when the green industry has “finished” developing software. As the industry changes and evolves, so does the software needed to manage it. Software is the foundation of any healthy business in this day and age. To be competitive, technology is a required tool. It is no longer an option to go without, and the key is simplicity not complexity.

Each department in a growing operation has unique business process needs that must be met. Over time, the business process and the requirements of each department can change, and so must the software. Typical widget software often creates more work — and workarounds — for the user. Widgets are built for businesses with higher margins and often require an army of users to continuously update the massive amounts of data.

Widget software creates more user labor and unnecessary complexity, which results in higher hidden costs. The negative impact on the business is vastly underestimated. Growers also face a more compressed season that requires faster adaptations within the software, thus compounding the high costs associated with using widget software, which is cumbersome and slower to update.

Software developers should be constantly refining and adjusting the software to find simpler ways for users to complete their work, all in the effort to reduce user labor and software complexity. As a general rule, the more complicated the software is to set up and use, the less profit the company secures from using it.

The five tools highlighted here are just a few of our clients’ favorite features. Some features are new and just coming onto the market; yet, they all make it simpler to plan and execute actions in less time, with fewer mistakes. The tools give users the ability to adapt to change, which is an everyday part of growers’ lives. The features presented here were built to help growers decrease the labor costs associated with managing their software, and to speed up the repetitive tasks that every grower dreads.

1. Forecast Tool

The Forecast Tool has simplified sales forecasts for our clients. Growers can forecast their sales individually for large customers, or by customer groups for smaller customers. The combination of these forecasts can be pushed into production to create the production schedule. The forecast being built into the system drives accountability to the production team, and later, to sales to meet their forecast. It puts an end to hours of Excel sheets outside the system that are disconnected, prone to errors and don’t tie into the production plan. The Forecast Tool brings accountability to the team.

If you’re losing sales, it’s nice to know why. The Forecast Tool will help you target the reason for your losses. Perhaps you didn’t produce the product on time and failed to meet sales requests? Or, you did produce the product on time, but sales didn’t move the product as promised? Understanding the weaknesses in the business will help growers save pennies, which add up to dollars, which add up to a healthy business.

2. Size BOM

Size BOM has dramatically decreased the labor- intensive process of setup and management of bill of materials. Using the Size BOM tool, clients can set up unique components — such as pot, tag and UPC code — for when potting for Home Depot versus Lowes, for example. The shared components of each customer are on the BOM. When a customer is entered into the schedule, the unique components for that customer are automatically added onto the BOM.

The efficiency of using Size BOM greatly reduces the labor associated with managing BOMs. When the forecast-by-customer is pushed into production, the customer is assigned to the crop in the schedule and the Size BOM allocates the unique BOM components.

This feature saves growers from manually building unique components for each and every single customer. Need we say more?

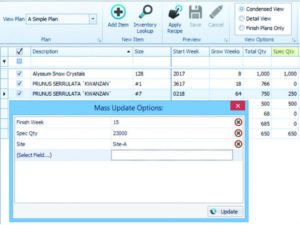

3. Mass Update BOM, Recipes and More

With the mass update feature, growers can cut down the hours to minutes of time they spend making big changes in recipes, BOMs and schedule. They now have the ability to update many fields of similar varieties all at once. The ability to mass update numerous records at once has reduced the labor associated with managing all production recipes, schedules and BOMs.

Growers can customize grow time, loss percentage, start size, and much more with the mass update tool. At SBI, we call most grower software “soul killers” because typical packages require growers to open a form, edit it, close it, and repeat the process over and over again. (Just reading that is exhausting!)

An Excel-like interface allows direct-edits in a grid so users don’t have to open another form. This feature reduces two to three clicks per edit down to one. The user ends up saving vast amounts of time when managing hundreds of varieties in production.

The days of open, edit, close, open, edit, close, are over. The Mass update feature combined with the Excel-like user interface expertly reduces user labor. When growers use mass update, they can select many records to update and pick multiple fields to update all at once, versus editing them individually.

Mass update is truly a time-saver. What are you going to do with all that excess time? Make more money? Grow your business?

4. PO Generator and Subbing

Several SBI clients have reported a two-day job compressed down to two or three hours thanks to the PO Generator. The PO Generator shows the client a list of items that need to be ordered based on the production schedule. The PO Generator auto-generates purchase orders in mass as opposed to clients manually writing each purchase order one by one. The PO Generator is used for ordering all of the raw materials: seed, plugs, liners and hard goods.

Subbing is an enormous time-depleting monster. Subbing consumes the majority of client time when they are building their plan and making purchases. Subbed items flow right through to the production schedule, creating new recipes and inventory items in the system.

Subbing is done in a few short seconds from the PO Generator through schedule. Global duplicate copies recipes, BOM, sizes, racking, pricing and so much more. If you’re feeling a little insanity, try subbing. Put your insanity to an end. Be assured; it does make the job easier.

5. All Digital Purchasing

All Digital Purchasing is the next “big ticket” item being we will be releasing. The availability of plugs and liners will be live in the SBI system for clients. The PO Generator will allow clients to send requests digitally to vendors. There will be no more need for emailing, faxing, making phone calls or sending telegrams! All Digital Purchasing will confirm the buying of all plant material digitally.

With the growing industry’s tight margins, no operation will prosper without the right technology. The time has come for the green industry to modernize along with the rest of the world. Growers must adapt and adopt technology to stay competitive.

Video Library

Video Library